4D68 ENGINE (E- W) -

Crankshaft, Cylinder Block and Flywheel

11A-12-5

CYLINDER BLOCK

(1) Visually check for cracks, rust, and corrosion, and inspect

the cylinder block using a flaw detecting agent. Rectify

defects where possible or replace the cylinder block.

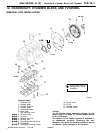

(2) Check th e cylinder block’s top surface for distortion using

a straight edge and thickness gauge. Be sure to make

measurementswith thestraightedge placedin thedirection

of A, B,.. a n d G as shown in the illustration. Before

measurements, make sure that the top surface is free

of gasket chips and other foreign material. If the distortion

is excessive, replace t he cylinder block.

Standard value: 0.05 mm

Limit: 0.1 mm

(3) Check the cylinder sleeve wall for scratches and seizure.

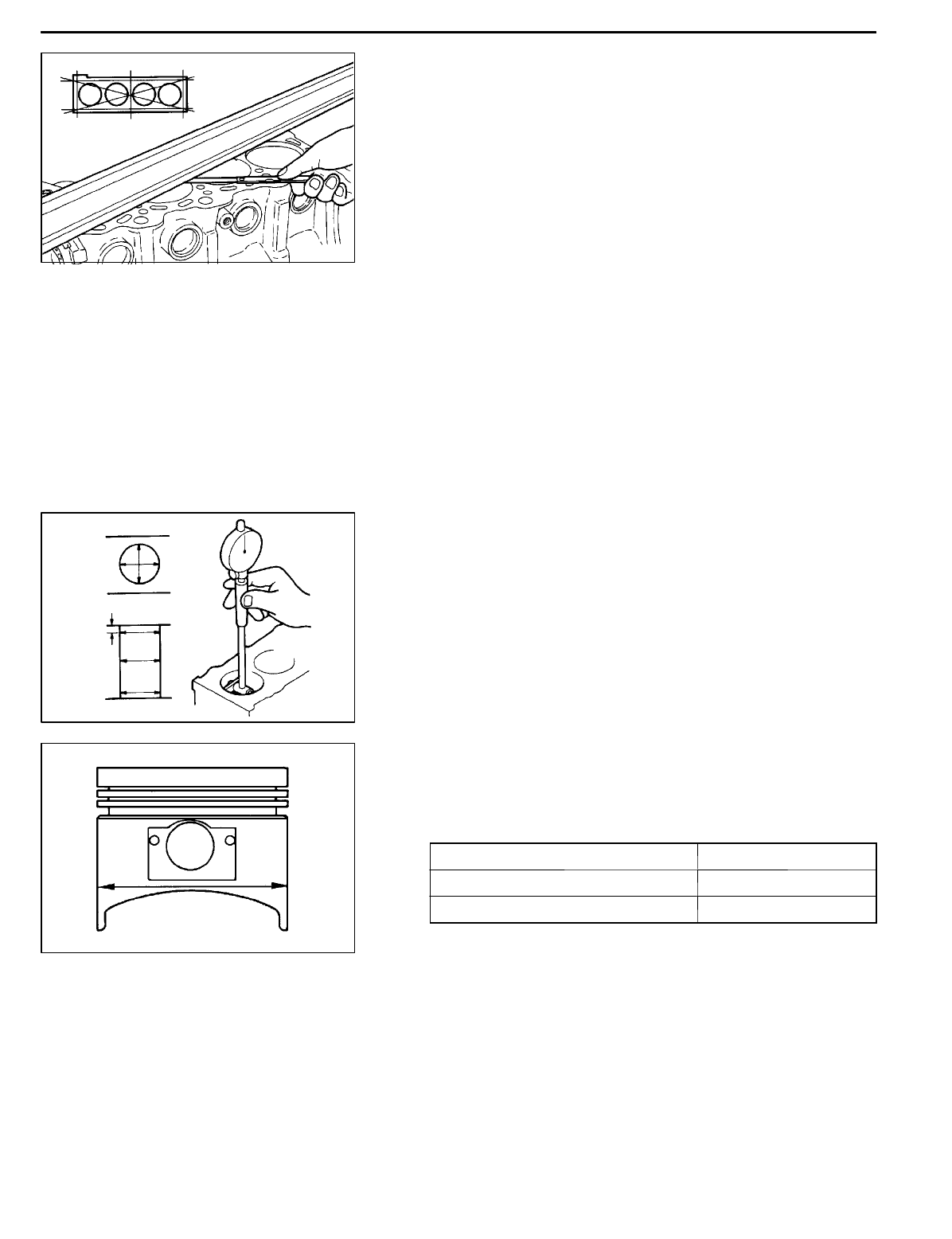

If defects areevident, replace the cylinder sleeve.Measure

the cylinder sleeve inner diameter at the points shown

in the illustration. If it is badly worn, replace.

Standard value: 82.70 - 82.73 mm

Conicity: 0.01 mm

BORING CYLINDER

(1) Oversize pistons to be used should be determined on

the basis of the largest bore cylinder.

Piston size identification

Size Identification mark

0.50 mm O.S. 0.50

1.00 mm O.S. 1.00

NOTE

Size mark is stamped on the piston top.

(2) Measure outside diameter of piston to be sued. Measure

it in thrust direction as shown.

(3) Based on the measured piston O.D., calculate the boring

finish dimension.

Boring finish dimension = Piston O.D. + (Clearance

between piston O.D. and cylinder) - 0.02 mm

(honing margin)

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

9EN0074

A

B

CD E

F

G

6EN0553

12 mm

Bottom

Center

A

B

6EN0554

Piston O.D.

Thrust

direction