RVS-DX, Digital Soft Starter Instruction Manual—4/01/04

5-3

Start/Stop Features

The RVS-DX incorporates many features that assist in starting and/or stopping various applications.

These features are described within this section.

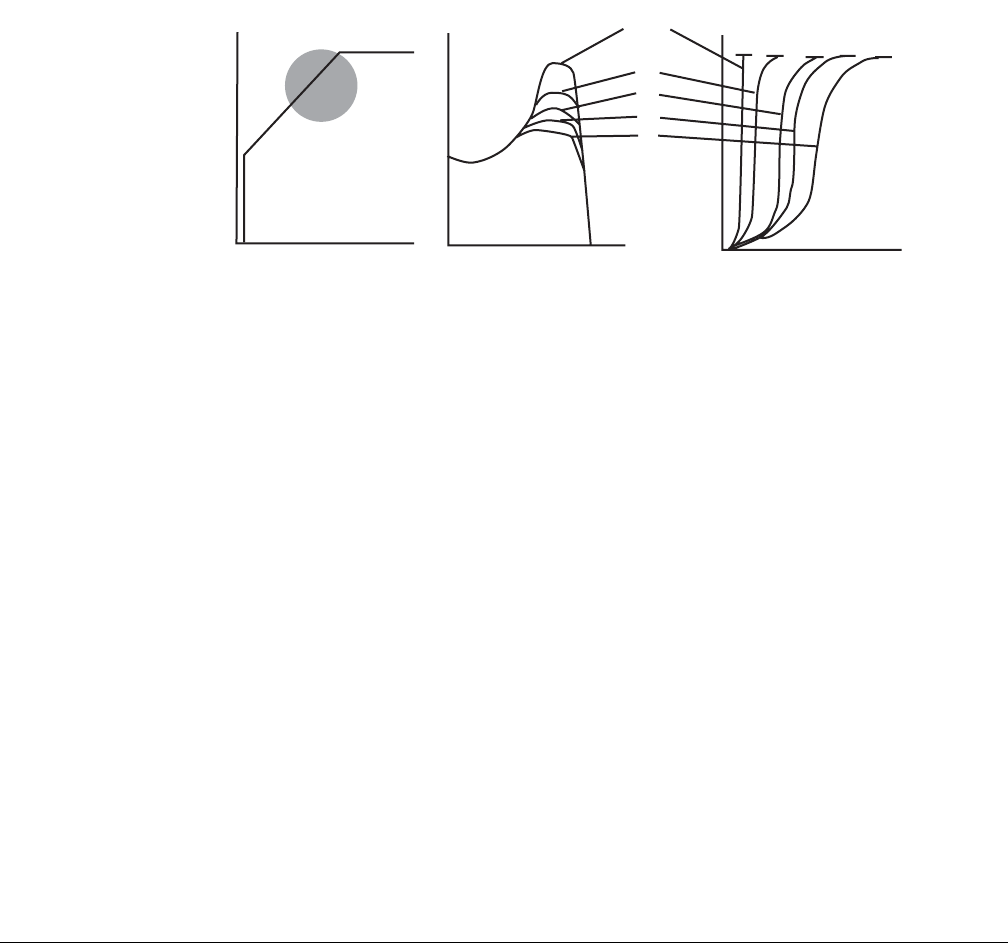

Pump Control (Start Curves)

Induction motors produce peak torque up to three times the rated torque. This peak torque can occur

towards the end of the starting process. In pump applications, this peak torque may cause high

pressure in the pipes.

The RVS-DX incorporates four different starting curves. The start curve (curve 0) is the standard

curve and the default. It is the most stable and suitable curve for the motor, preventing prolonged

starting and motor overheating. Pump start curves (1, 2, and 3) automatically control the voltage

ramp-up to reduce peak torque. The multiple starting curves are shown below:

NOTE: Always start with Start curve 0. If towards end of acceleration, peak torque is too high,

proceed to curve 1, then 2 and 3 if necessary.

Tach Feedback (0-10 VDC)

The tach feedback provides linear acceleration and deceleration curves according to RPM feedback.

Twelve tachometer gain levels can be selected for closed loop control for starting and stopping.

NOTE: Always begin with minimum gain (0) and proceed with higher gain levels if required.

Pulse Start

The pulse start feature is used to break away high friction loads. High friction loads may require

close to across the line starting torque for a very short duration of time. The pulse start feature

accomplishes this with an 80% voltage boost (without current limit) for a period of 0.1 to 1 second.

After this pulse, the voltage is ramped down to the initial voltage setting where it begins ramping up

again to full voltage.

V

oltage

Torque

DOL

0

1

2

3

Speed

Tim

e