1

2

4

3

5-3E

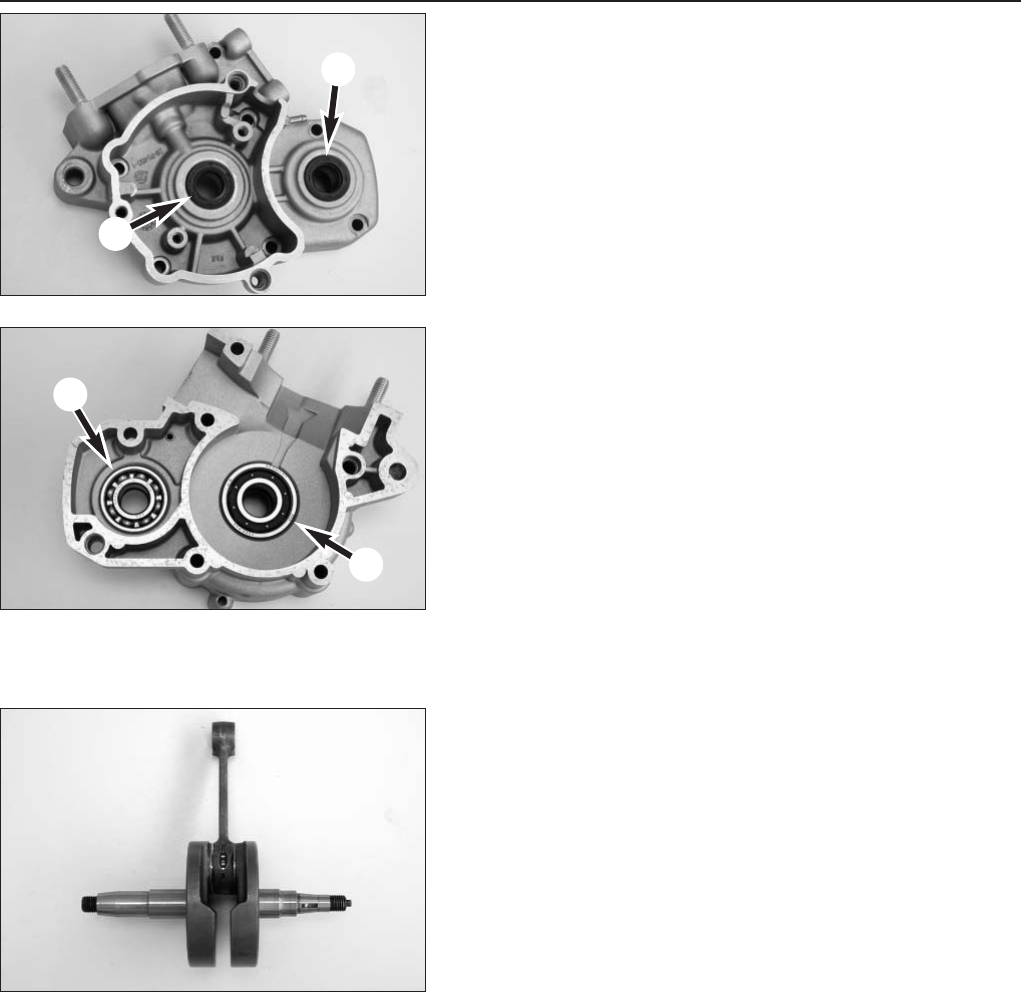

Working on the left half of the engine case

Remove shaft sealing rings 1/2 and heat engine case halves on a

heating plate to approx. 150° C.

NOTE:

– If the engine case is heated to 150° C and struck on a wooden

surface, the bearings usually fall out of the bearing seats

automatically. If necessary, the bearings must be pushed out.

– The devices (mandrels) to press the new bearings in place should be

designed such that they only rest on the outer ring of the bearing,

otherwise the bearings will be damaged when fitted.

Grooved ball bearing for crankshaft

3

Use a suitable mandrel to press the grooved ball bearing into place.

Press the new grooved ball bearing all the way in.

NOTE: the grooved ball bearing of the crankshaft will protrude approx.

1 mm from the surface of the case.

Grooved ball bearing for output shaft

4

Use a suitable mandrel to press the grooved ball bearing into place.

Press the new grooved ball bearing all the way in.

NOTE: the grooved ball bearing of the output shaft should fit flush with

the surface of the case.

Shaft sealing ring for crankshaft

1

Press a new shaft sealing ring into place with the sealing lip to the

inner side.

After the engine case halves have cooled, check bearings for firm

retention.

Measure the crankshaft

If continuing to use the crankshaft, check crankshaft journal for lateral

runout.

The lateral runout of the crankshaft journal should be no more than

0.05 mm

NOTE: Conrod bearing and crankshaft can only be checked in

dismantled condition, this should be done in a special workshop.