Setup

Continued onnext page JS56696,00005061909DEC081/3

TCM Calibration

PC11066—UN—29FEB08

TCM Calibration

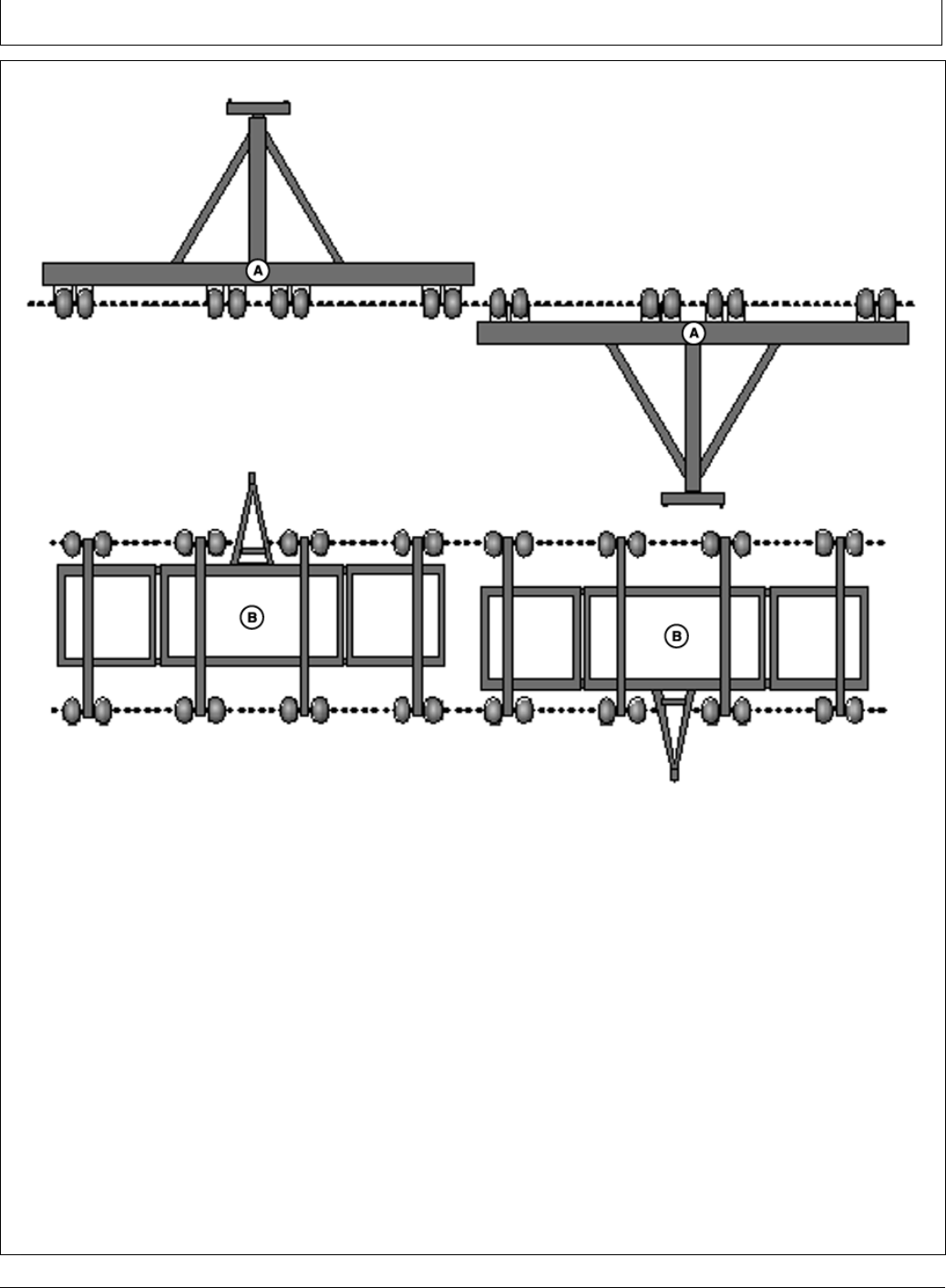

A—Implement with one main axle B—Implement with carrying

wheels at the front and rear

One of the most important steps in making iGuide function

at its peak performance is the TCM Calibration for both

the machine and implement. If the TCM calibration is

not performed correctly then a bias could occur in the

machine, implement or both. A bias is when the machine

AutoTracs down and back on the same path and the wheel

tracks do not line up. This can be caused by a poor TCM

calibration or the receiver is not centered on the machine.

A bias can be fixed by either recalibrating the TCM or

entering a machine or implement GPS lateral offset.

NOTE: When checking for bias, turn iGuide to “none”

and use AutoTrac to check the machine bias.

If you need to check implement bias, use

iGuide. Use Straight track only.

NOTE: When performing a TCM calibration on the

implement receiver, the wheels of the main

frame need to be in the same location after

turning implement around so that the righthand

wheels are in the same place as where the

lefthand wheels were.

NOTE: A TCM calibration should be performed

each time the receiver is moved to a different

implement or vehicle.

Tips for a good TCM calibration:

•

Let the receiver warm up for 10—15 minutes, especially

if the air temperature is cold.

•

Calibrate on a flat surface.

•

Make sure the machine or implement are level with

respect to the ground by having proper tire inflation,

correct ballasting, and the same tire sizes.

•

Follow diagram example for proper rotation of

implement during the calibration process.

For more information refer to your StarFire iTC users

manual.

1515

102110

PN=28