SOLID STATE ECONOMIZER SYSTEM

63-2484—2 8

CAUTION

Personal Injury Hazard.

Spring-return assembly can release.

Leave end covers attached to the motor.

Location and Mounting

Locate motor as close as possible to the equipment to be

controlled. Refer to Fig. 4 for mounting dimensions.

1. Mount motor with the shaft horizontal to ensure maxi-

mum life.

NOTE: Operation in other positions is possible when required

by the application.

2. Remove crank arm (secured with two screws) from the

motor hub.

IMPORTANT

Position crank arm on hub so it does not strike motor

mounting surface during any portion of full stroke.

See Fig. 8.

3. Reposition the crank arm to accommodate specific

damper requirements.

NOTE: Crank arm position is adjustable in eight degree

increments.

4. Reconnect crank arm to the motor hub.

5. If there is an excess length of linkage rod, cut it to size.

Make necessary minor adjustments until desired opera-

tion is obtained.

6. Tighten all nuts and set screws.

Fig. 8. Limits of crank arm rotation.

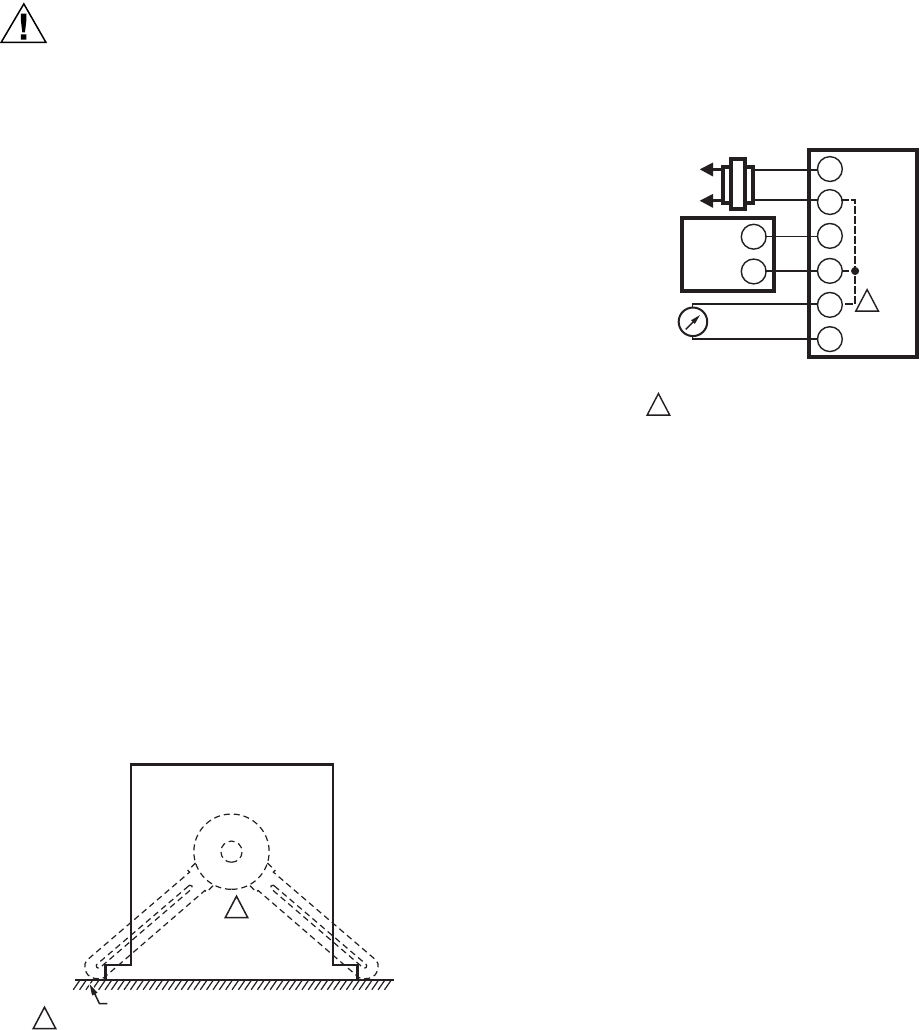

WIRING: M7215, M7415, M8405

All wiring must comply with applicable codes and ordinances.

Refer to Fig. 9 for typical hookup.

Fig. 9. Typical M7215 wiring.

C7046C Discharge Air Temperature Sensor

The sensor assembly consists of an aluminum sensor probe

(element housed internally) with attached flange that can be

mounted on a flat duct or plenum surface, or in a 2 in. by 4 in.

(51 by 102 mm) junction box, using two no. 8 screws.

Connections to the sensor are made through two 6 in. (152

mm) leadwires.

Location

Locate the sensor in the air duct or plenum where it can

sample average air temperature. Avoid locations where air

stratification can cause sensing errors.

Mounting

To mount the C7046C Sensor on a flat duct or plenum surface

(see Fig. 10):

1. Cut a 1/2 in. (13 mm) hole in the duct or plenum surface

at the desired location.

2. Insert the sensor probe into the duct or plenum hole until

the flange rests against the duct or plenum wall.

3. If necessary, use the flange as a template to mark and

drill two holes for no. 8 mounting screws.

4. Fasten the sensor to the duct or plenum surface with the

two no. 8 sheet metal screws (not provided).

1

1

CRANK ARM FIELD ADJUSTABLE IN 7.5 DEGREE INCREMENTS.

MOTOR MOUNTING SURFACE

M3850

MAXIMUM

OPEN

POSITION

MAXIMUM

CLOSED

POSITION

M17365

TR1

TR

M7215

2-10

VDC

CONTROL

METER INDICATING

MOTOR POSITION

(2-10 VDC)

L1

L2

IN+

OUT

–

IN–

+

–

OUT

+

DOTTED LINE REPRESENTS INTERNAL

CONNECTIONS OF THE M7215 ACTUATOR.

1

1