locknut and turn the adjuster nut on the

handbrake primary rod (photo).

3 Raise the rear roadwheels and check that

they turn freely when the handbrake lever is

fully released.

17 Handbrake cable -

renewal

1

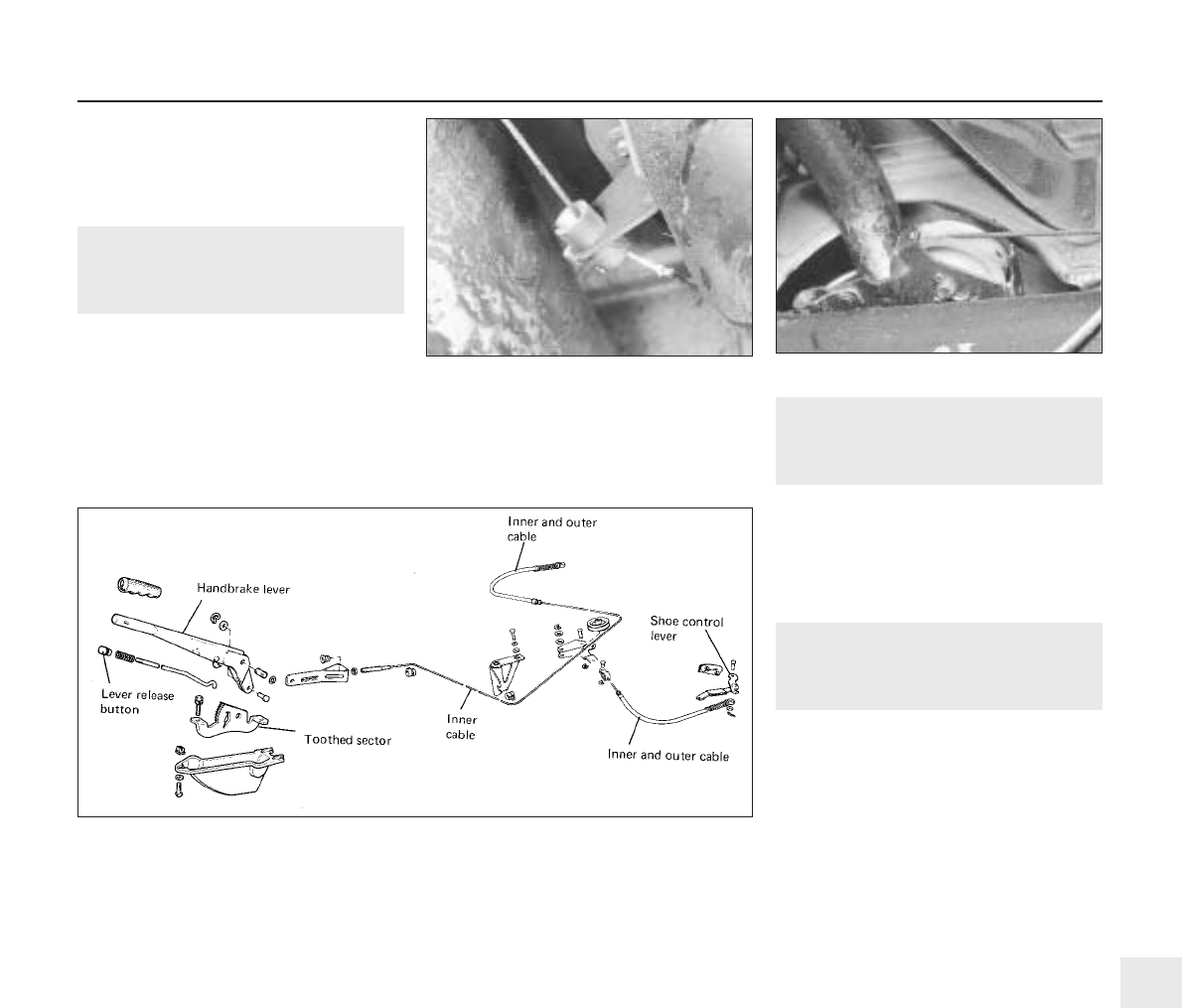

1 There are two cables, either of which may

be renewed independently

2 Disconnect the cable, which is to be renewed,

from the shoe lever at the brake backplate.

3 Disconnect the longer cable from the

primary link or rod and release the cable from

its retainers. On later models with a plastic

fuel tank, a cable bracket is moulded into the

side of the tank (photo).

4 Disconnect the shorter cable from the pivot

lever at the pulley on the rear axle (photo).

5 Refit the new cables by reversing the

removal operations and then adjust as

described in the preceding Section.

18 Brake pedal -

removal and refitting

1

1 The operations are described in

conjunction with the clutch pedal in Chapter

5, Section 4.

2 The brake pedal pushrod will slide out of

the servo unit as the pedal is withdrawn.

19 Stop lamp switch

1

1 The brake stop lamp switch is of plunger

type acting on the pedal arm.

2 Adjust the position of the switch by turning

the locknuts until the stop lamps illuminate

when the pedal arm is depressed through 1.0

mm (0.039 in).

Braking system 8•9

Fig. 8.13 Handbrake components (Sec 17)

17.4 Handbrake cable pulley

17.3 Handbrake cable guide on fuel tank

8

Fault finding - braking system

Excessive pedal travel

ⅥⅥ Pads or shoes excessively worn

ⅥⅥ Incorrect pedal or servo pushrod adjustment

ⅥⅥ Automatic adjusters faulty

ⅥⅥ Seized wheel cylinder or caliper piston

ⅥⅥ Master cylinder seals worn

Pedal feels spongy or soggy

ⅥⅥ Air in hydraulic system

ⅥⅥ Low fluid level

ⅥⅥ Loose connections

ⅥⅥ Flexible hose perished

ⅥⅥ Defective wheel cylinder or caliper seal

Pedal feels springy

ⅥⅥ New pads or linings not bedded-in

ⅥⅥ Master cylinder mounting loose

Pedal vibrates when brakes applied

ⅥⅥ Discs or drums distorted

ⅥⅥ Friction linings excessively worn

ⅥⅥ Loose backplate or caliper mounting bolts

ⅥⅥ Wear in steering or suspension components

Excessive effort required to stop car

ⅥⅥ Worn or contaminated linings or pads

ⅥⅥ Incorrect grade of lining or pad material

ⅥⅥ Servo vacuum hose leaking or disconnected

ⅥⅥ Faulty servo or non-return valve (55 or 70 models)

ⅥⅥ Seized caliper or wheel cylinder piston

ⅥⅥ One circuit defective on dual circuit hydraulic system

Brakes pull to one side

ⅥⅥ Friction linings contaminated on one side of car

ⅥⅥ Seized hydraulic piston on one side of car

ⅥⅥ Different types of linings fitted on different sides of car, or new

linings on one side only

ⅥⅥ Seized automatic adjuster on one side of car

Brakes drag

ⅥⅥ Handbrake linkage overadjusted or seized

ⅥⅥ Seized caliper or wheel cylinder piston

Brakes squeal

ⅥⅥ Drums or discs rusty or damp (temporary fault - no action

necessary)

ⅥⅥ Dust or grit in brake drums

ⅥⅥ Linings excessively worn