advance points than the earlier system.

Comparison of Fig. 13.82 with Fig. 4.2

illustrates the difference in layout. Note that

the distributor is mounted on the rear end of

the cylinder head and is driven by the

camshaft.

63 When working on the Digiplex 2 ignition

system or associated components, the

precautionary notes outlined in Section 9 of

Chapter 4 must be adhered to.

64 As with the earlier system, test

procedures possible on the Digiplex 2 system

are restricted due to the need for specialised

testing equipment. The following checks are

possible, however, using a conventional test

meter.

Ignition coil check

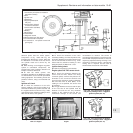

65 To check the resistance of the coil’s

primary windings, connect the probes of an

ohmmeter between the positive terminal and

the negative terminal as shown in Fig. 13.83,

and check that the resistance reading at 18 to

28ºC is 0.45 ohms ± 10% (photo).

66 To check the resistance of the coil’s

secondary windings, connect the probes of an

ohmmeter between the positive terminal and

the HT lead terminal as shown in Fig. 13.84.

Check that the resistance reading at 18 to

28ºC (64 to 82ºF) is 4800 ohms ± 10%.

Ignition timing check

67 Refer to paragraph 2 in this Section.

Engine speed and TDC sensor check

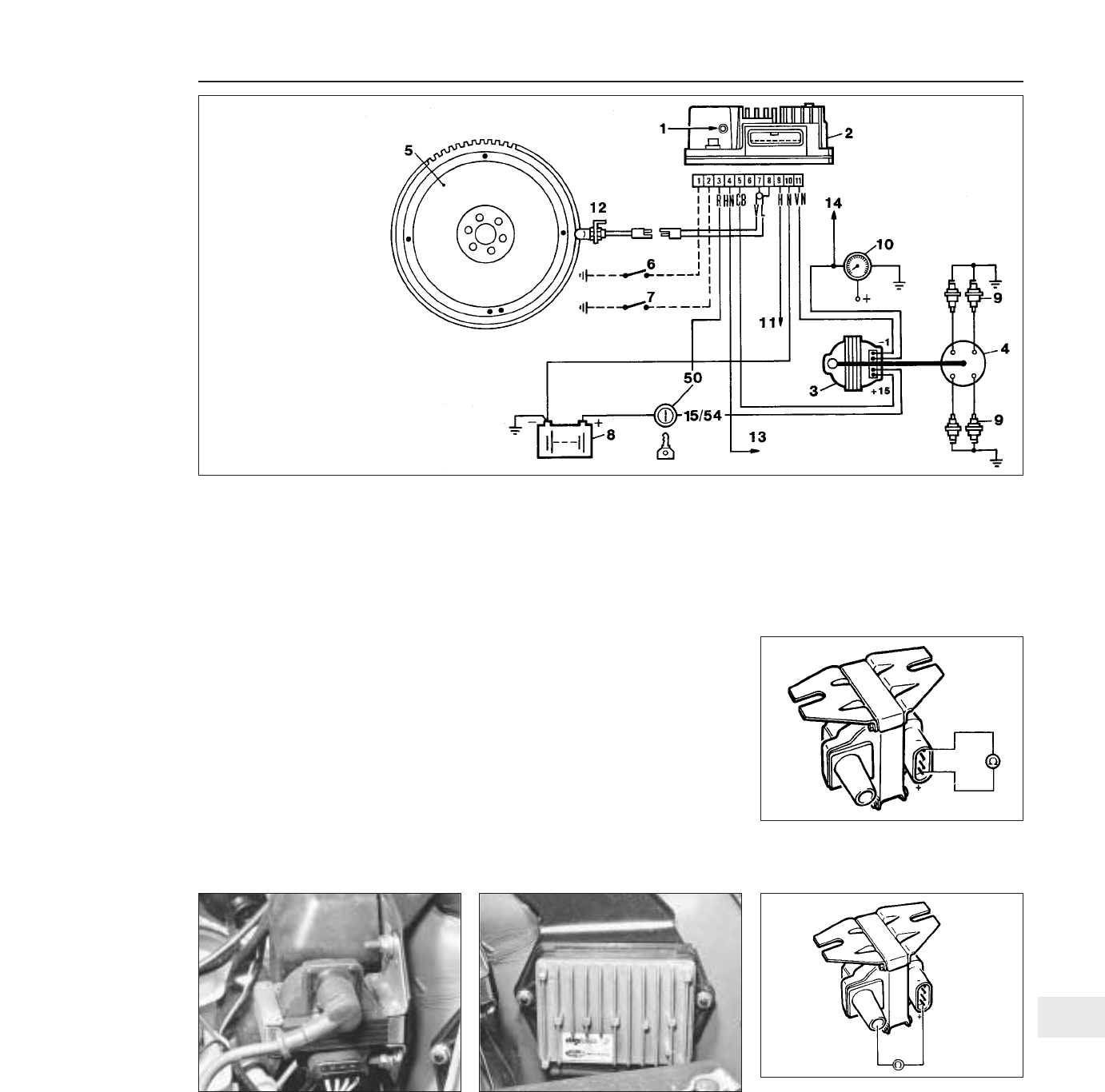

68 To check the resistance between the

sensor and the ECU, detach the wiring

connector (photo). Connect the probes of an

ohmmeter to the connector terminals and

check that the resistance reading is between

600 and 760 ohms at 20ºC (68ºF). If the

reading is not as specified, the sensor must

be renewed.

69 The gap between the sensor and the pins

on the rear face of the flywheel must be

between 0.2 and 0.8 mm. Any deviation

outside of this clearance will be due to

mechanical damage to the sensor and

necessitates its renewal. The sensor is

accurately positioned during manufacture and

secured with tamperproof screws; it does not

require any adjustment during servicing. If it is

necessary to renew the sensor, a special gap

setting tool is required and the task is

therefore best entrusted to a FIAT dealer.

Supplement: Revisions and information on later models 13•91

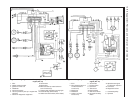

Fig. 13.82 Digiplex 2 ignition system wiring circuits and components (Sec 10)

10.68 ECU location on the 1372 cc ie

engine

10.65 Ignition coil and connections on the

1372 cc ie engine

Fig. 13.84 Test connections for ignition

coil secondary windings check - Digiplex 2

ignition system (Sec 10)

Fig. 13.83 Test connections for ignition

coil primary windings check - Digiplex 2

ignition system (Sec 10)

13

1 Connection point (lines connected to

the intake manifold)

2 ECU

3 Ignition coil

4 Distributor

5 Engine flywheel (with

five pins)

6 On/off switch (if fitted)

for advance reduction

7 On/off switch 2 (if fitted)

for curves

8 Battery

9 Spark plugs

10 Tachometer

11 Diagnostic socket

12 Engine speed and TDC sensor

13 To check actuator idle speed

14 To terminal no. 1 of injection control unit

(rpm signal)