from the suspension struts and then remove

the bolts which secure the hub carriers to the

U-clamps at the base of the suspension

struts.

23 Pull the tops of the hub carriers down and

then outwards and push the driveshafts from

them.

24 Unbolt the driveshaft inboard boot

retainers and then remove the driveshafts

from the transmission.

25 Support the engine on a hoist or use a

trolley jack under the engine/transmission.

Remove the bottom mounting and then the

upper left and right-hand ones.

26 Lower the power unit to the floor by

pushing it to the left-hand side to clear the

right-hand mounting bracket and then swivel

the gearbox towards the rear of the car.

Withdraw the engine/transmission from under

the car.

27 External dirt and grease should now be

removed using paraffin and a stiff brush or a

water-soluble solvent.

28 Unbolt and remove the engine mounting

brackets and the starter motor.

29 Unbolt and remove the cover plate with

the gearchange ball stud strut from the lower

front face of the flywheel housing.

30 With the engine resting squarely on its

sump pan, unscrew the flywheel housing

connecting bolts, noting the location of any

lifting lugs and hose and wiring clips.

31 Support the weight of the transmission

and withdraw it in a straight line from the

engine.

36 Engine - dismantling (general)

Refer to Section 14, Part 2.

37 Engine ancillary components

- removal

Refer to Section 15, Part 2 and also remove

the intake manifold.

38 Engine -

complete dismantling

3

1 Have the engine resting squarely and

supported securely on the work surface.

2 Unbolt and remove the timing belt cover.

3 Grip the now exposed timing belt with the

hands and loosen the camshaft sprocket.

4 Release the timing belt tensioner pulley

centre bolt, then slip the belt from the pulley

and sprockets to remove it. Note which way

round the belt is fitted, usually so that the

lettering on the belt can be read from the

crankshaft pulley end of the engine.

5 Remove the camshaft sprocket.

6 Unbolt and remove the camshaft timing belt

cover backing plate.

7 Unbolt and remove the camshaft carrier

cover.

8 Unbolt the camshaft carrier and lift it off

very slowly, at the same time pushing the cam

followers and their shims down with the

fingers securely onto their respective valve

springs. It is easy to remove the camshaft

carrier too quickly with some of the cam

followers stuck in it and as the carrier is lifted

away, the cam followers will fall out. If this

happens, the valve clearances will be upset as

the cam followers and shims cannot be

returned, with any certainty, to their original

positions. Keep the cam followers and shims

in their originally fitted order.

9 Unscrew and remove the cylinder head

bolts and nuts, grip the manifold, rock the

head and remove the complete cylinder

head/manifold/carburettor assembly. Remove

and discard the cylinder head gasket.

10 Unbolt the coolant pump from the side of

the cylinder block and remove it complete

with coolant distribution pipe. Remove the

crankcase breather.

11 Remove the distributor/oil pump

driveshaft. This is simply carried out by

inserting a finger into the hole vacated by the

distributor and wedging it in the hole in the

end of the driveshaft. Lift the shaft out of

mesh with the auxiliary shaft. Where the

distributor is driven by the camshaft, a cover

plate retains the oil pump driveshaft in

position.

12 Unbolt and remove the sprocket from the

end of the auxiliary shaft. The sprocket is held

to the shaft with a Woodruff key.

13 Unbolt the auxiliary shaft retainer and

withdraw the shaft from the crankcase.

14 Unscrew and remove the crankshaft

pulley nut. This is very tight and the flywheel

starter ring gear will have to be jammed with a

cold chisel or a suitably bent piece of steel to

prevent the crankshaft rotating.

15 Withdraw the crankshaft sprocket, which

is located by the Woodruff key.

16 Unbolt the front engine mounting bracket

from the cylinder block, together with the

timing belt cover screw anchor bush. Unbolt

and remove the timing belt tensioner pulley.

17 Unscrew the flywheel securing bolts. The

starter ring gear will again have to be jammed

to prevent the crankshaft rotating as the bolts

are unscrewed. Mark the flywheel position in

relation to the crankshaft mounting flange,

then remove it.

18 Unbolt the front and rear crankshaft oil

seal retainer bolts from the crankcase and the

sump. Remove the oil seal retainers.

19 Turn the engine on its side, extract the

remaining sump bolts and remove the sump.

If it is stuck, try tapping it gently with a

soft-faced hammer. If this fails, cut all round

the sump-to-gasket flange with a sharp knife.

Do not try prising with a large screwdriver; this

will only distort the sump mating flange.

20 With the sump removed, unbolt and

remove the oil pump.

21 Grip the oil pick-up pipe and twist or rock

it from its hole in the crankcase. It is an

interference fit in the hole.

22 Remove the piston/connecting rods as

described in Section 32.

23 Before unbolting the main bearing caps,

note that they are marked with one, two, three

or four notches. No. 5 main bearing cap is

unmarked. Note that the notches are nearer

the auxiliary shaft side.

24 Unbolt and remove the main bearing

caps. If the bearing shells are to be used

again, tape them to their respective caps. The

bearing shell at the centre position is plain,

the others have a lubricating groove.

25 Carefully, lift the crankshaft from the

crankcase, noting the thrust washers at No. 5

main bearing. These control the crankshaft

endfloat.

39 Cylinder head - dismantling

and decarbonising

4

1 The operations are similar to those

described for the ohv engine in Section 17 in

respect of decarbonising and valve grinding.

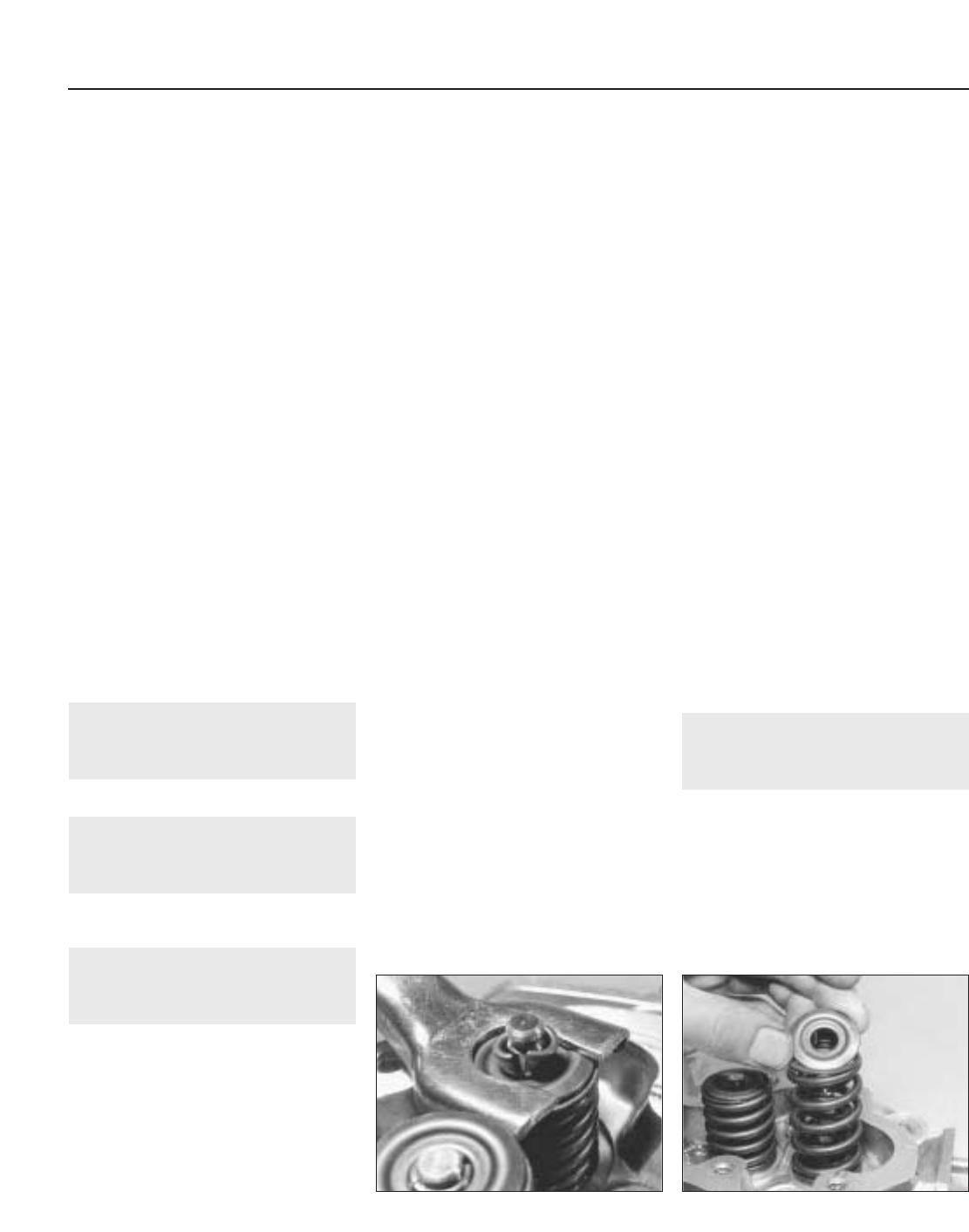

2 To remove a valve, use a valve spring

compressor to compress the first valve and

then extract the split collets (photo).

3 Release the valve spring compressor.

4 Withdraw the valve spring cap and the

double valve springs (photos).

5 Remove the valve (photo).

1•28 1116 cc and 1301 cc engine

39.4A Valve spring cap39.2 Valve spring compressor and split

collets