16 Engine -

complete dismantling

3

1 Unbolt and remove the rocker cover.

2 Unscrew the rocker pedestal securing nuts

and lift away the rocker assembly.

3 Remove the pushrods, keeping them in

their original fitted order.

4 Remove the cylinder head as described in

Section 7. Remove the dipstick and guide

tube.

5 Turn the engine on its side and unbolt and

remove the sump pan.

6 Remove the piston/connecting rods as

described in Section 9.

7 Unscrew and remove the crankshaft pulley

nut. To prevent the crankshaft rotating while

this is done, either jam the flywheel ring gear

or place a block between a crankshaft

counterweight and the inside of the

crankcase.

8 Unbolt and remove the timing cover.

9 Remove the timing chain and sprockets as

described in Section 6.

10 Unbolt and remove the oil pump as

described in Section 10.

11 Unscrew and remove the camshaft front

bearing lockscrew noting that the chamfer on

the bearing is on the inboard side.

12 Withdraw the camshaft, taking great care

not to damage the bearings with the cam

lobes.

13 Lift out the cam followers and keep them

in their originally fitted sequence.

14 Unbolt and remove the flywheel. Jam the

ring gear teeth to prevent rotation.

15 Remove the engine rear plate.

16 Turn the cylinder block so that it is

standing upside down.

17 Unbolt and remove the crankshaft rear oil

seal carrier. Note the sump fixing studs.

18 The main bearing caps should be marked

1, 2 and 3 but if they are not, centre punch

them and note which way round they are

located.

19 Unscrew the main bearing cap bolts

progressively.

20 Remove the bearing caps and half shells.

If the shell bearings are to be used again,

keep them with their respective caps.

21 Note the semi-circular thrust washers on

either side of the centre main bearing which

control crankshaft endfloat.

22 Lift the crankshaft from the crankcase.

23 Remove the bearing shells from the

crankcase and mark them as to position if

they are to be used again.

17 Cylinder head - dismantling

and decarbonising

4

1 The exhaust manifold and rocker gear will

have been removed from the cylinder head

during removal (see Section 7).

2 The valves should now be removed using a

universal valve spring compressor.

3 Compress the first valve spring and extract

the split cotters.

4 Gently release the compressor, take off the

spring retaining cap, the valve spring and the

spring seat. Remove the valve. Keep the valve

with its associated components together and

in numbered sequence so that they can be

returned to their original positions.

5 A small box with divisions is useful for this

purpose. Remove and discard the valve stem

oil seals.

6 Remove the other valves in a similar way.

7 Bearing in mind that the cylinder head is of

1•16 903 cc engine

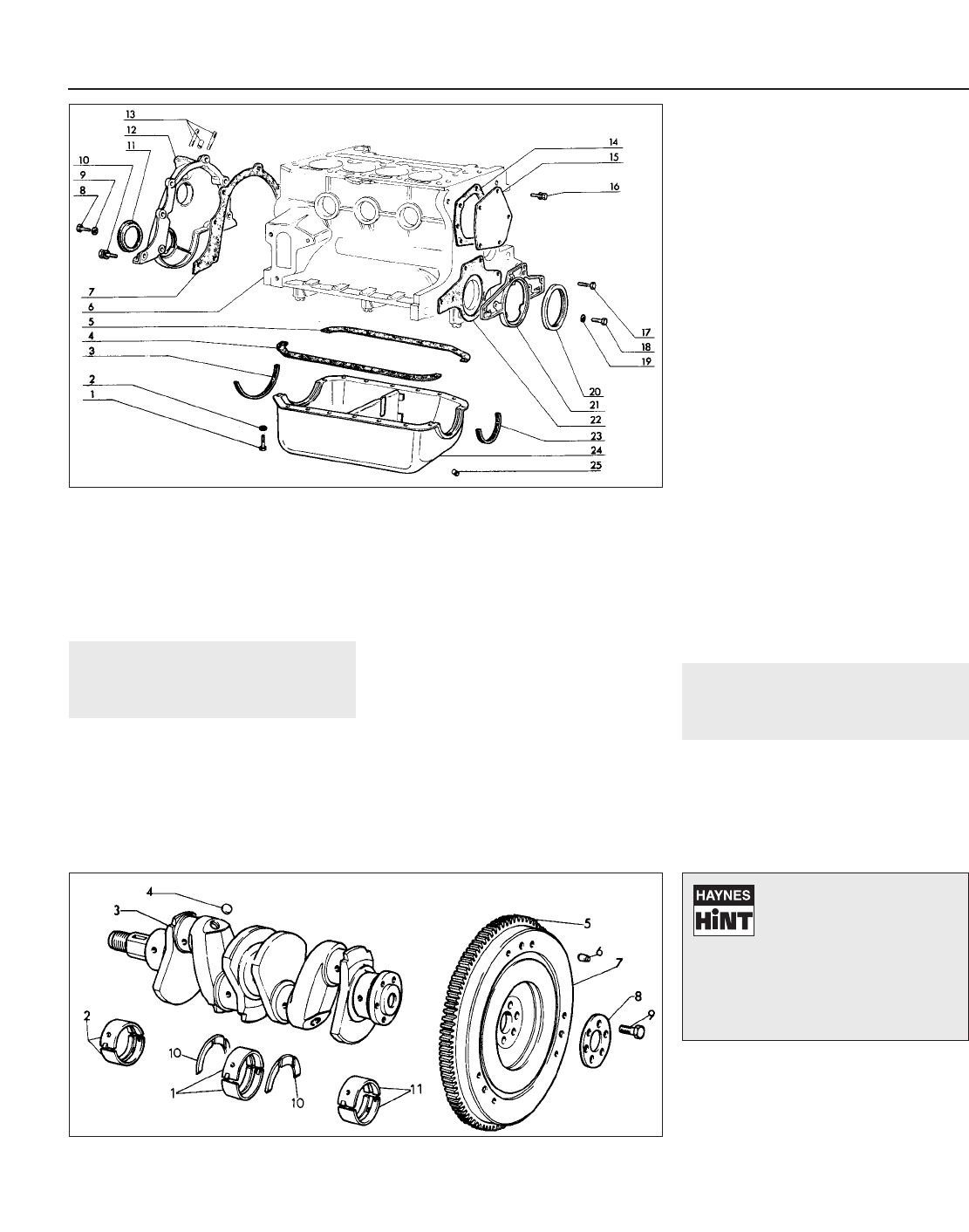

Fig. 1.23 Timing cover, sump pan and oil seals (Sec 16)

Fig. 1.24 Crankshaft and flywheel (Sec 16)

1 Sump pan bolt

2 Washer

3 Sealing strip

4 Side gasket

5 Side gasket

6 Block/crankcase

7 Gasket

8 Bolt

9 Washer

10 Bolt and washer

11 Crankshaft front oil

seal

12 Timing cover

14 Gasket

13 Fuel pump studs

and bush

15 Cover plate

16 Bolt and washer

17 Bolt

18 Bolt

19 Washer

20 Crankshaft rear oil

seal

21 Oil seal carrier

22 Gasket

23 Sealing strip

24 Sump pan

25 Drain plug

1 Centre main

bearing shells

2 Front main bearing

shells

3 Crankshaft

4 Plug

5 Starter ring gear

6 Dowel

7 Flywheel

8 Thrust plate

9 Bolt

10 Thrust washers

11 Rear main bearing

shells

If the valve spring refuses to

compress, do not apply

excessive force, but remove

the compressor and place a

piece of tubing on the spring retainer

and strike it a sharp blow to release the

collets from the valve stem. Refit the

compressor and resume operations

when the collets should come out.