pump jet and give ten full strokes of the

throttle lever, pausing between each stroke to

allow fuel to finish dripping.

8 The total volume of fuel collected should be

between 2.5 and 4.5 cc. Adjust the nut on the

pump control and if necessary to increase or

decrease the volume of fuel ejected.

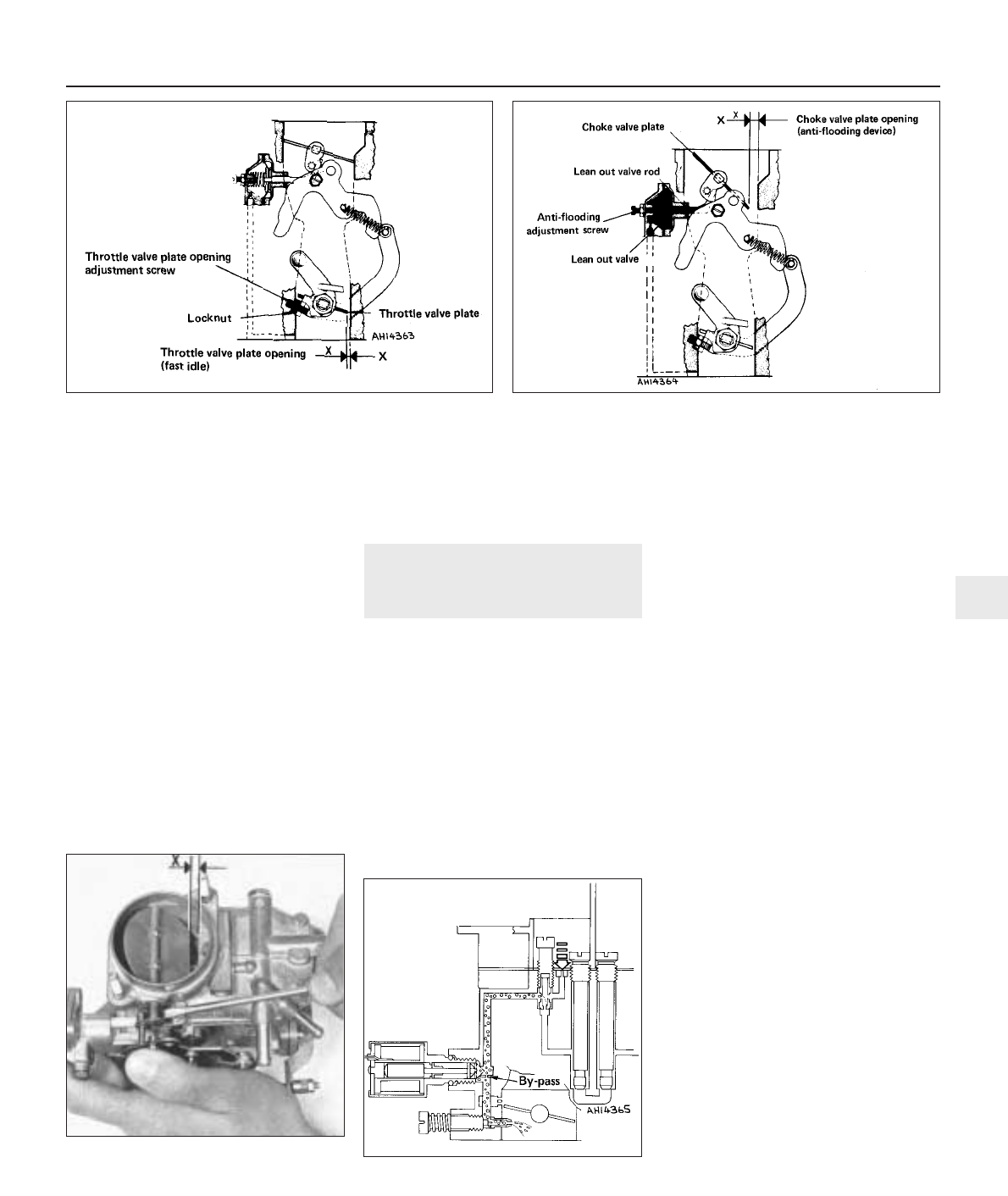

Fast idle adjustment

9 With the choke valve plate fully closed, the

throttle valve plate should be open to give a

dimension (X) (Fig. 3.18) of between 0.90 and

1.0 mm (0.035 to 0.039 in). Use a twist drill of

suitable diameter to measure the gap. If

necessary, adjust by means of the screw and

locknut.

Anti-flooding device

10 Close the choke valve plate by means of

the control lever. At the same time, push the

lean out valve rod towards the valve.

11 There should be a gap (X) (Fig. 3.19)

between the edge of the choke valve plate

and the carburettor throat of between 4.75

and 5.25 mm (0.187 to 0.207 in). Adjust if

necessary by means of the screw and locknut

on the lean out valve.

11 Carburettors (Weber 32 ICEE/

250 and Solex C32 DISA 14) -

description and adjustment

4

1 One of these carburettors is used on

903 cc ES engines. They are very similar to

the Weber 32 ICEV 50/250 and Solex

C32 DISA 11 already described in this

Chapter except that a fuel cut-out solenoid

valve is fitted in association with the Digiplex

ignition system (see Chapters 4 and 9).

2 The solenoid valve cuts off the supply of

fuel to the carburettor whenever the

accelerator pedal is released during overrun

conditions.

3 A fuel cut-out device control unit receives

information regarding engine speed from the

static ignition control unit.

4 A throttle butterfly switch relays information

that the accelerator pedal is in the released

state.

5 At certain minimum idle speeds during

deceleration, the fuel cut-out solenoid valve is

re-energised so that engine idling is

maintained without the tendency to cut out.

6 The Solex type control unit varies the fuel

cut-out point according to the deceleration

value.

Fault testing

7 Should a fault develop, connect a test lamp

between the fuel cut-out solenoid switch and

a good earth.

8 Connect a reliable tachometer to the engine

in accordance with the maker’s instructions.

9 Start the engine and raise its speed to

between 3000 and 4000 rev/min, then fully

release the accelerator pedal.

10 The test lamp should only go out during

the period when the accelerator pedal is

released. Should the test lamp remain on all

the time, or never come on, check the throttle

switch earth and the solenoid switch

connections.

11 Disconnect the multi-plug from the control

unit. Switch on the ignition and check that a

test lamp connected between contact 7 of the

multi-plug and earth will illuminate. If it does

not, there is an open circuit from connection

15/54 of the fuel cut-off switch.

12 Switch off the ignition and check for

continuity between contact 3 of the multiplug

and earth. An ohmmeter will be required for

this test.

13 If there is no continuity (ohmmeter shows

infinity), check all the system earth

connections. Also check that the wiring plug

under the control unit is properly connected.

14 Finally, check the engine speed signal. To

do this, a tachometer must be connected to

the single socket under the control unit within

the engine compartment.

15 If the tachometer registers correctly then

this confirms that the electronic ignition

Fuel system 3•9

Fig. 3.18 Fast idle adjustment diagram (Solex C32 DISA 11)

(Sec 10)

X = 0.90 to 1.0 mm (0.035 to 0.039 in)

Fig. 3.19 Anti-flooding device adjustment diagram

(Solex C32 DISA 11) (Sec 10)

X = 4.75 to 5.25 mm (0.187 to 0.207 in)

Fig. 3.21 Sectional view of fuel cut-off

switch (Solex C32 DISA 14) (Sec 11)

Fig. 3.20 Moving lean out valve rod

(Solex C32 DISA 11) (Sec 10)

X = 4.75 to 5.25 mm (0.187 to 0.207 in)

3