28 Loosen off the retaining clips and detach

the air intake pipe from the air filter.

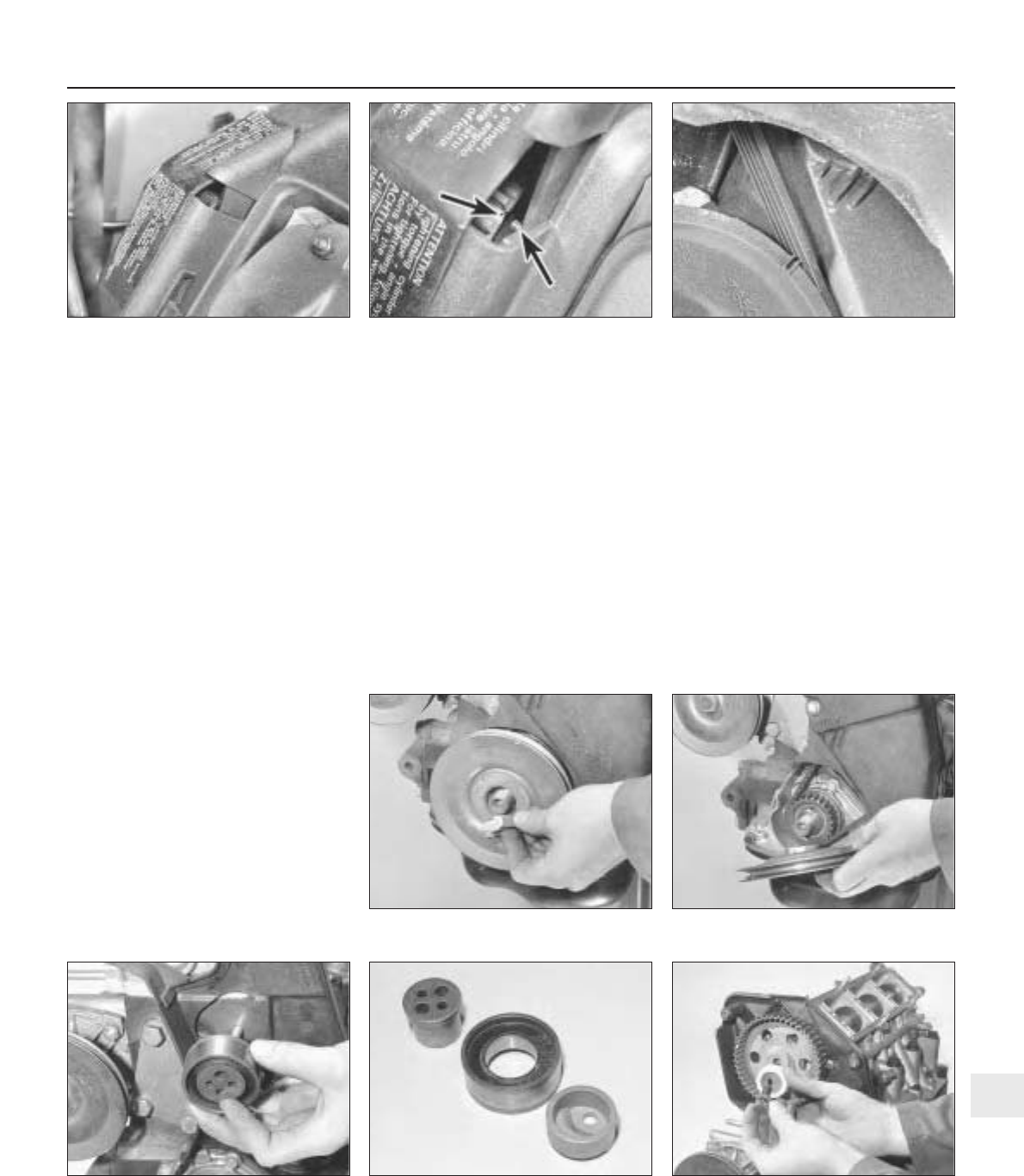

29 Slide back the inspection cover from the

upper end of the timing cover (photo).

30 Turn the engine over by hand to bring the

TDC timing marks of the flywheel-

to-bellhousing and the camshaft sprocket

-to-rear cover projection into alignment. The

crankshaft pulley also has a TDC timing mark

and this should be positioned as shown

(photos).

31 Loosen off the retaining and adjustment

strap fixings, then pivot the alternator towards

the engine.

32 Unscrew the upper retaining bolts

securing the timing cover.

33 Loosen off the nut securing the alternator

and its drivebelt relay, then detach and

remove the alternator drivebelt.

34 Unscrew and remove the crankshaft

pulley nut. Where the engine is in the car,

prevent the crankshaft from turning by

engaging top gear and having an assistant

apply the brake pedal hard. Unscrew and

remove the flywheel housing lower cover bolts

and remove the cover. The flywheel ring gear

can now be jammed with a suitable lever or

implement to prevent the crankshaft from

rotating. It should be noted that the pulley nut

is tightened to a considerable torque and a

strong socket, together with an L-bar and

extension tube, will therefore be required to

loosen and remove it (photo). Take care not to

damage the gearbox/flywheel housing by

jamming the flywheel at a weak point.

35 Withdraw the crankshaft pulley (photo).

36 Unscrew and remove the lower retaining

bolts and remove the timing cover upwards

from the vehicle.

37 Check that the previously mentioned

timing marks are still in alignment. Loosen off

the timing belt tensioner nut, then with the

tension released, withdraw the timing belt

from the sprockets.

38 To remove the drivebelt tensioner, undo

the securing nut and withdraw the tensioner

pulley unit noting that it is in three sections

(photos).

39 If desired, the sprockets and the rear

timing belt cover can be removed as follows,

otherwise proceed to paragraph 49.

40 To remove the camshaft sprocket, a

suitable tool must be used to hold the

camshaft stationary as the sprocket bolt is

loosened. A suitable tool can be improvised

as shown in photo 7B.48 using two pieces of

steel bar joined together by a pivot bolt, with

suitable bolts through the ends of the steel

bars to engage with the holes in the sprocket.

41 Unscrew the sprocket bolt, then recover

the plain washer, and the thrust washer which

is bonded into a plastic sleeve (photo).

42 The sprocket can now be withdrawn from

the end of the camshaft. If the sprocket is

tight, carefully lever it from the camshaft using

two screwdrivers, but take care not to

damage the rear timing belt cover.

43 The crankshaft sprocket can be removed

by simply pulling it from the end of the

Supplement: Revisions and information on later models 13•39

7B.30B Crankshaft pulley and timing cover

timing marks

7B.30A Camshaft sprocket timing notch

aligned with timing (TDC) pointer in timing

case

7B.29 Slide back inspection cover in the

timing case

7B.41 Removing the crankshaft sprocket

bolt, plain washer and thrust washer

7B.38B The three sections of the timing

belt tensioner

7B.35 Crankshaft pulley removal7B.34 Crankshaft pulley nut removal

7B.38A Timing belt tensioner removal

13