balljoint from the hub carrier using a suitable

“splitter” tool. If such a tool is not available,

support the base of the brake disc and drive

the balljoint taper pin downwards, but screw

on the nut to protect the threads.

4 Remove the hub carrier.

5 Refitting is a reversal of removal, use a new

driveshaft nut and tighten all nuts and bolts to

the specified torque. Stake the driveshaft nut

after tightening.

6 Track control arm -

removal and refitting

3

1 Raise the front of the car and support it

securely.

2 Unless a special tool is available to press

the track control arm balljoint from the hub

carrier, the driveshaft will have to be

disconnected as described in Chapter 7,

Section 2, paragraphs 1 to 8 to provide more

space to enable the balljoint taper pin to be

driven from the hub carrier. This should now

be done as described in the preceding

Section (photo).

3 Unbolt the inboard end of the track control

arm. This is retained by a pivot bolt and a

clamp (photo).

4 As previously explained, a worn balljoint or

flexible pivot bushes will necessitate renewal

of the track control arm complete. Note that it

may, however, be possible to obtain a

replacement balljoint through a motor factor.

5 Refitting is a reversal of removal. Tighten all

nuts and bolts to the specified torque. Use a

new driveshaft nut and stake it into the

driveshaft groove after tightening.

7 Front crossmember -

removal and refitting

3

1 Raise the front of the car, support securely

with axle stands placed under the

side-members or sill jacking points.

2 Remove the front roadwheels.

3 Unscrew the nuts from the tie-rod end

balljoint taper pins and then using a balljoint

“splitter” tool disconnect the balljoints from

the steering arms on the hub carrier.

4 Unscrew the bolts which hold the inboard

track control arms to the body members, and

also withdraw the pivot bolt from the body

bracket.

5 Support the weight of the engine/

transmission using a hoist or support bar

across the top of the engine compartment as

described in Chapter 6.

6 Disconnect the lower (central) engine/

transmission flexible mounting from the floor

pan.

7 Unscrew the steering rack mounting bolts

and remove them. Leave the steering rack

hanging loose.

8 Remove the front crossmember mounting

bolts and manoeuvre it from the car.

9 Refitting is a reversal of removal. Tighten all

nuts and bolts to the specified torque wrench

settings and on completion, check the front

wheel alignment as described in Chapter 10.

8 Rear shock absorber -

removal and refitting

3

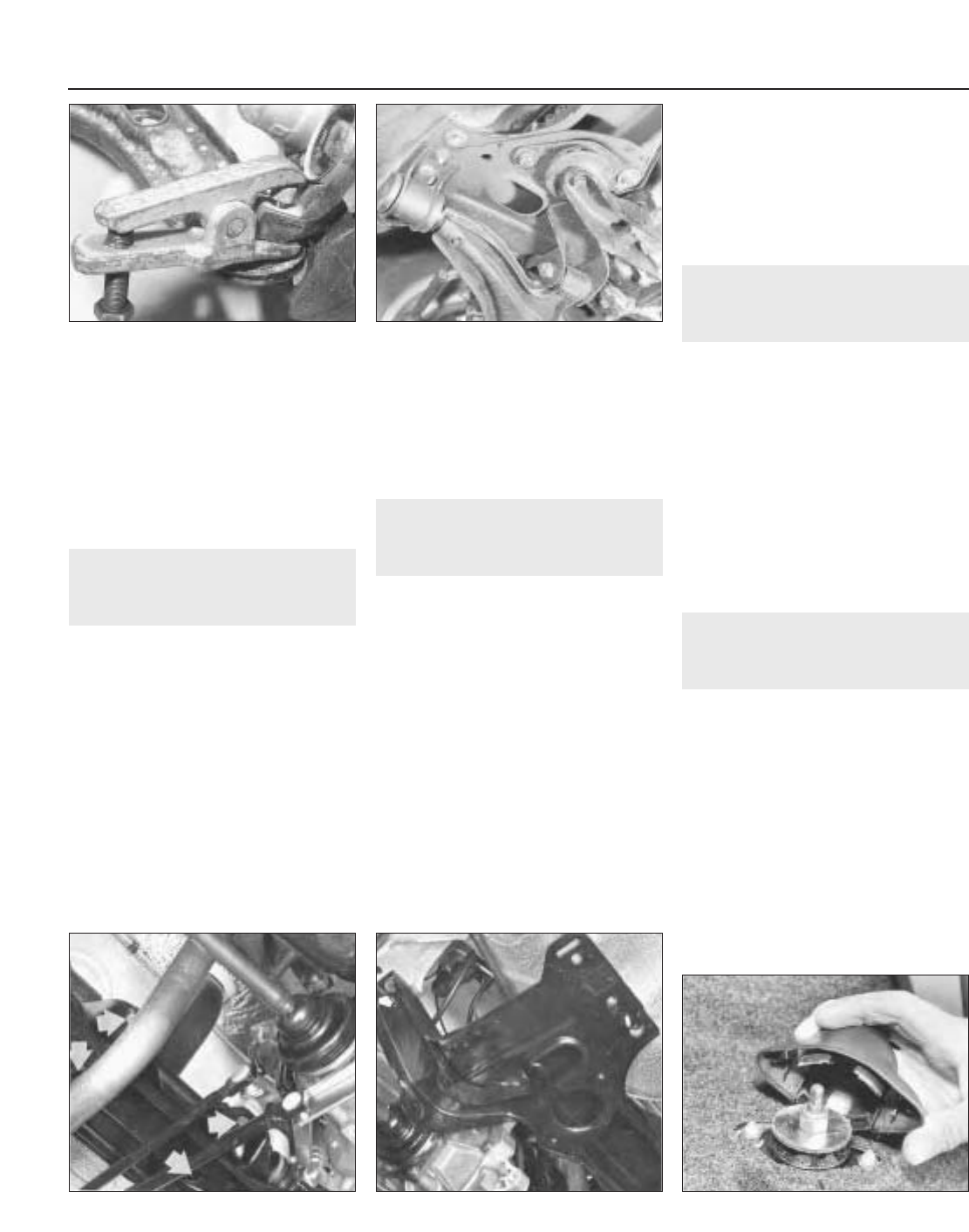

1 Open the tailgate and remove the cover

from the shock absorber top mounting which

is located within the luggage area (photo).

2 Hold the flats on the spindle with an

open-ended spanner and then unscrew the

self-locking nut.

3 Working under the car, disconnect the

shock absorber lower mounting.

4 Withdraw the unit from under the wing.

5 The shock absorber can be tested as

described in Section 2.

6 Refitting is a reversal of removal. Tighten

mounting nuts and bolts to the specified

torque.

9 Rear coil spring -

removal and refitting

3

1 Raise the rear of the car and support it

securely on axle stands placed under the

side-members or sill jacking points.

2 Remove the roadwheel.

3 Place a jack under the brake drum and

support the suspension trailing arm.

4 Disconnect the shock absorber lower

mounting and then lower the trailing arm jack

until the coil spring can be withdrawn.

5 Refitting is a reversal of removal. If the

spring is being changed, make sure that it is

of the same colour code as the original and

that its lower coil is correctly located up

against its stop in the spring pan.

6 Tighten the shock absorber lower mounting

bolt to the specified torque.

11•4 Suspension

8.1 Rear shock absorber upper mounting

cover

Fig. 11.7 Front crossmember bolts (Sec 7)Fig. 11.6 Steering rack mounting bolts

(Sec 7)

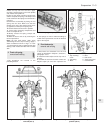

6.3 Track control arm inboard fixing6.2 Separating track control arm balljoint

from hub carrier