Idle speed and mixture

adjustment ¢

29 Before carrying out any adjustments, the

engine must be at operating temperature, the

fan having cut in at second speed and then

switched off.

30 Release the locknut and turn the main idle

speed screw in the throttle valve housing until

the engine idles at the specified speed. This

should be all that is necessary to obtain the

correct idle speed, as the throttle valve plate

base setting is set during production.

However, if wear has taken place, or incorrect

adjustment has been carried out previously,

proceed in the following way.

31 Disconnect the intake duct from the

throttle valve housing. Release the locknut on

the base (small) adjusting screw, and turn the

screw until there is a clearance between the

lower edge of the throttle valve plate and the

throat wall of between 0.05 and 0.1 mm

(photos).

32 With the engine still at operating

temperature, start the engine, and having

released the locknut, turn the main (large) idle

speed screw fully clockwise to close the

bypass passage.

33 Now turn the base (small) screw until the

engine idles at between 700 and 800 rpm.

Tighten the locknut.

34 Finally, turn the main (large) adjusting

screw to give an idle speed of between 800

and 900 rpm.

35 It is unlikely that the mixture will require

alteration, but if it does, connect an exhaust

gas analyser to the car in accordance with the

equipment manufacturer’s instructions.

36 With the engine at operating temperature,

prise out the tamperproof cap, and turn the

mixture screw, which is located in the airflow

meter, until the CO level is as given in the

Specifications. Turning the screw clockwise

richens the mixture, turning it anti-clockwise

weakens the mixture. Use a close-fitting Allen

key for the adjustment (photo).

Fuel injection system -

electrical tests ™

37 When carrying out checks to trace a fault

in the system, an ohmmeter should be used

for the following tests.

38 Disconnect the multipin connector from

the ECU, and also the one from the system

control relay, and apply the probes of the

ohmmeter in accordance with the following

sequence to check for continuity in the

cables. The component wiring plug will of

course be disconnected for the test.

ECU connector Component connector

plug terminal plug terminal

1 1 of ignition coil

2 2 of throttle position

switch

3 3 of throttle position

switch

4 50 of ignition switch

5 Earth

5 5 of airflow meter

7 7 of airflow meter

8 8 of airflow meter

9 9 of airflow meter

9 9 of throttle position

switch

9 18 of supplementary air

valve

9 87 main relay socket

10 10 of coolant temperature

sensor

12 Injector terminals

13 Earth

System control Component connector

relay connector plug terminal

plug terminal

1 1 of ignition coil

15 15 of ignition switch

30 Battery positive

31 Earth

50 50 of ignition switch

87 Injector terminals

87 18 of throttle position

switch

87 9 of ECU multipin socket

87b Fuel pump (fused)

13•68 Supplement: Revisions and information on later models

Fig. 13.42 ECU and component connector plug terminals - 1301 cc Turbo ie engine (Sec 9C)

For colour code see main wiring diagrams

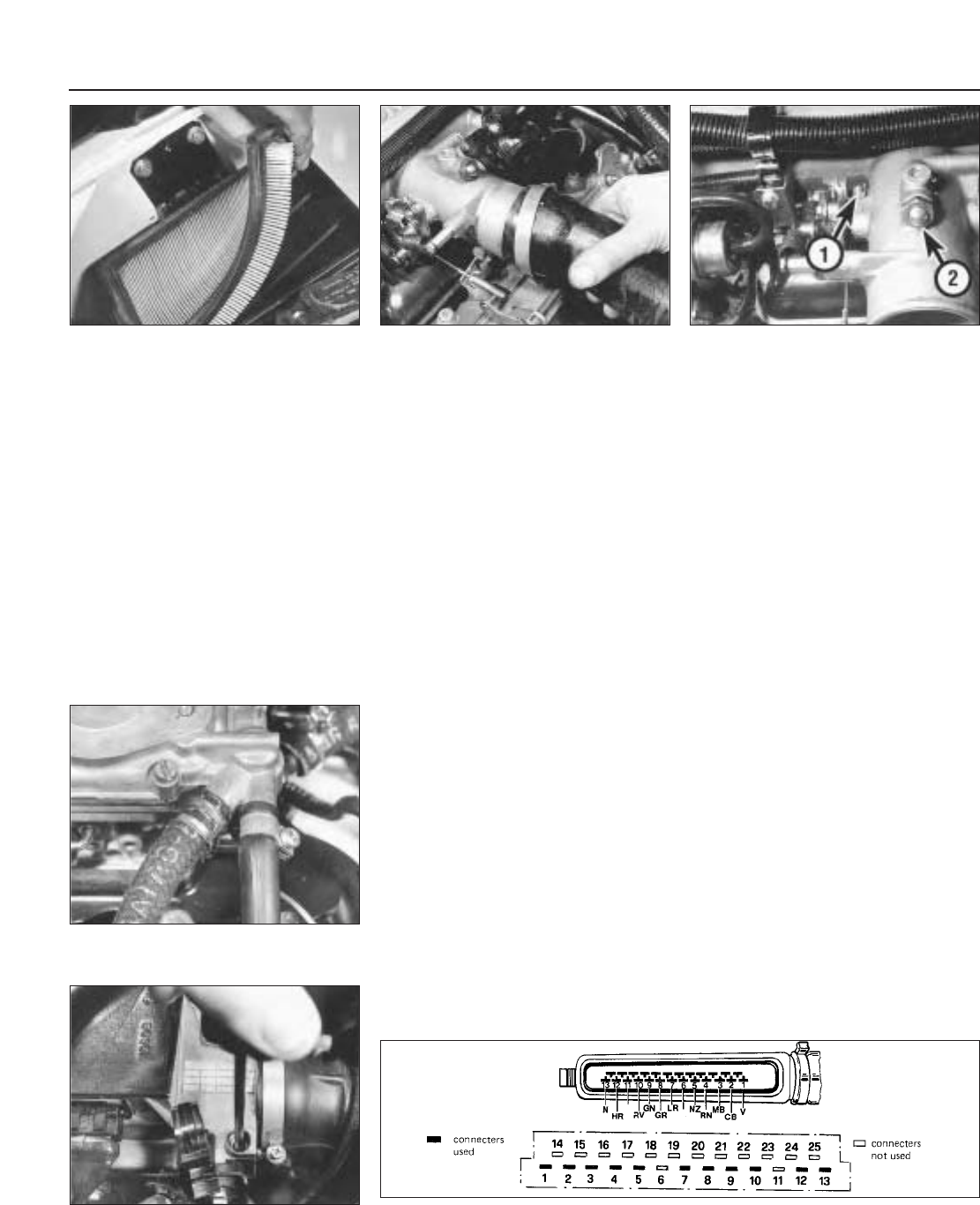

9C.31C Checking throttle valve plate

opening with a feeler blade

9C.36 Using an Allen key to adjust the

mixture (CO level)

9C.31B Idle speed base setting screw (1)

and main adjustment screw (2)

9C.31A Disconnecting the throttle valve

housing intake duct

9C.27B Removing the air cleaner element