32 Fit the hot air collector plate for the air

cleaner (photo).

33 Refer to Section 10 and fit the distributor.

34 Bolt on the timing belt cover.

35 Fit the camshaft cover, using a new

gasket unless the original one is in perfect

condition.

Engine/transmission -

reconnection and refitting #

36 Locate the engine in an upright position

on wooden blocks to allow for the greater

depth of the transmission flywheel housing

when it is joined to the engine.

37 Make sure that the clutch driven plate has

been centralised, offer the transmission to the

engine and locate the flywheel housing on the

single stud and dowels.

38 Tighten the connecting bolts to specified

torque, having located the lifting eye (photo).

39 Bolt on the starter motor.

40 Refit the cover plate to the flywheel

housing, but do not insert the lower bolts at

this stage as they retain the support bracket

for the gearchange rod.

41 The engine and transmission are now

ready for refitting. The operations are a direct

reversal of the operations described earlier,

but observe the following points.

42 Have the engine/transmission perfectly

horizontal and suspended on the hoist.

43 Lower it into position very slowly until it is

possible to engage the driveshaft inboard

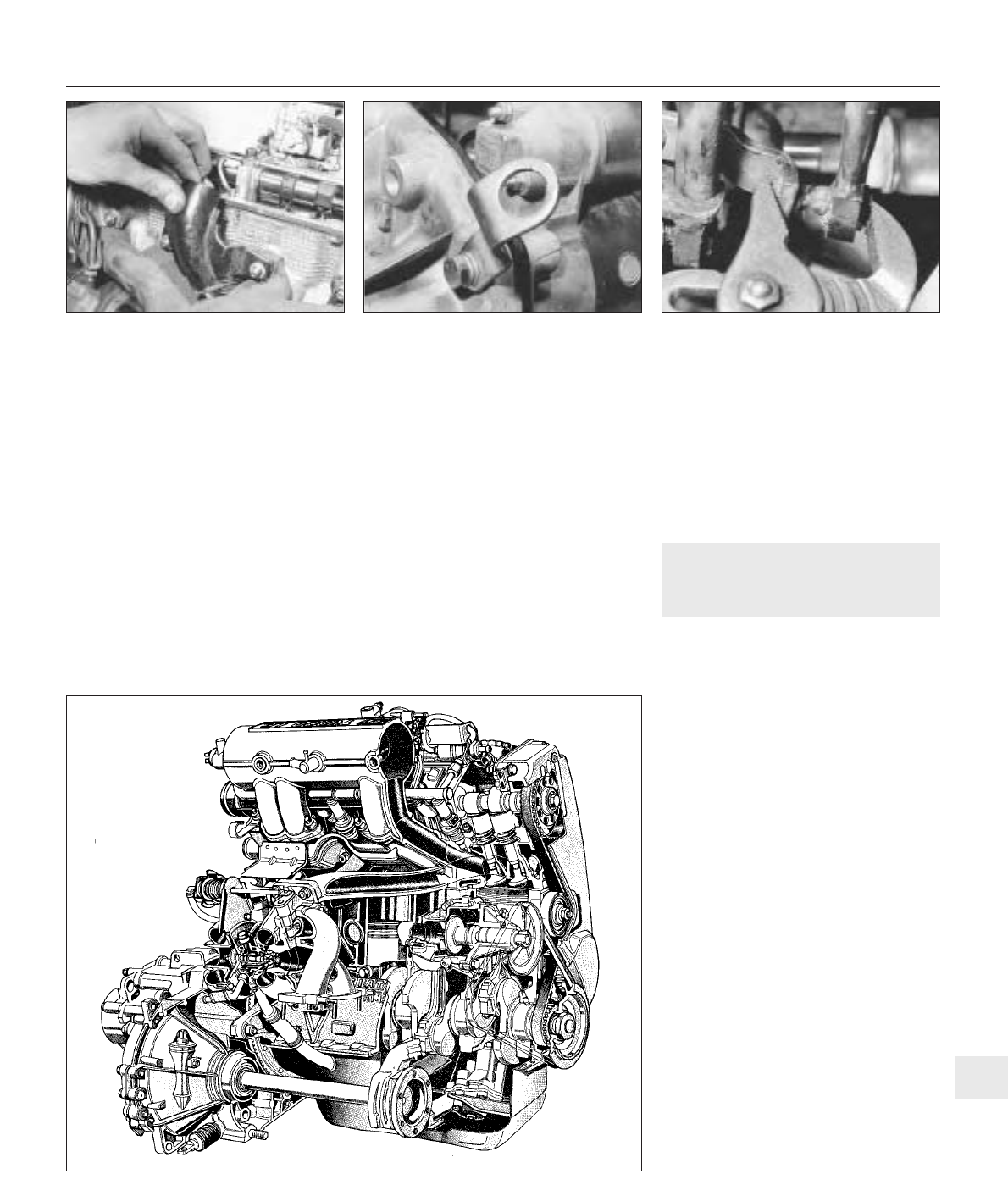

joints with the transmission.

44 Continue lowering until the driveshafts

can be fully engaged and the mountings

reconnected. Remove the hoist.

45 Tighten all nuts and bolts to the specified

torque. Note the method shown for

connecting the gearchange rod ball socket

using pliers (photo).

46 Refill the engine with oil and coolant and

replenish the transmission oil.

Initial start-up after major

overhaul

47 Refer to Chapter 1, Section 45.

6 Engine -

1301 cc Turbo ie

PART A: GENERAL

Description

1 This engine is similar in design to the

1301 cc engine described in Chapter 1, but

the fuel and ignition systems are different, and

a turbocharger, oil cooler and intercooler are

fitted.

2 Many dimensions and tolerances have

been altered for this engine, and reference

should be made to the Specifications at the

beginning of this Supplement.

3 Operations which differ from those

described in Chapter 1 are given in the

following sub-Sections.

Lubrication system - description

4 The lubrication system differs from the

non-Turbo 1301 cc engine in the following

respects.

5 An oil cooler is fitted, which comprises a

matrix with inlet and outlet hoses connected

to the oil filter cartridge mounting base.

6 A thermostatic control switch is fitted,

which diverts the oil flow through the matrix

only at oil temperatures above 84ºC (183ºF).

Note that a faulty switch will require renewal

of the complete oil filter mounting base.

7 Special oil spray nozzles are located in the

crankcase main bearing webs, to cool the

underside of the pistons.

8 The ball-type valves in the nozzles open

when the engine oil pressure reaches 1.2 bars

(17.4 lbf/in

2

).

9 An oil pressure sender unit is screwed into

Supplement: Revisions and information on later models 13•33

5D.45 Connecting ball socket type

gearchange rod

5D.38 Lifting eye on flywheel housing

flange

5D.32 Air cleaner hot air collector plate

Fig. 13.10 Cutaway view of the 1301 cc Turbo ie engine (Sec 6A)

13