fluid. They are “sealed”. Liquid will get in, but

a thorough clean will be impracticable, and it

will be impossible to get new grease in.

17 Check all the parts, get a new gland, two

new grommets, (1116 cc and 1301 cc) and a

new gasket. Scrape all deposits out of the

housing and off the impeller.

18 To reassemble, start by inserting the new

grommets (1116 cc and 1301 cc) in the

grooves by each bearing. Fit the circlip to the

shaft, then the shouldered ring, bearings and

spacer. Fit the shaft and bearing assembly

into the cover. Fit the stop screw. Press on

the pulley.

19 Fit the new gland (seal), seating it in its

location in the cover. Press the impeller onto

the shaft. The impeller must be put on part

way, and then the housing held in place to see

how far the impeller must go down the shaft

to give the correct clearance, which is 0.8 to

1.3 mm (0.03 to 0.05 in) as shown in Figs. 2.4

and 2.5.

20 The impeller clearance can be checked

through the coolant passage in the side of the

pump.

21 Refitting is a reversal of the removal

process, but use a new flange gasket and

tension the drivebelt as described in Section 8

(photo).

22 Refill the cooling system.

10 Cooling system sensors

1 A coolant temperature sender switch is

located in the cylinder head (above No. 1

spark plug) on 903 cc engines and adjacent to

No. 2 spark plug on 1116 cc and 1301 cc

engines.

2 The switch operates the coolant

temperature gauge and an excessive

temperature warning lamp.

3 On some models, a level sensor is screwed

into the side of the expansion tank. This

sensor consists of a pair of reed switches

within a capsule which are kept closed by the

strong magnetic flux generated by the

hydrostatic force inspired by the action of the

coolant against the float.

4 If the coolant level drops then the magnetic

flux is weakened and the switches open.

5 In the event of a fault developing, before

assuming that the cause is the sensor, check

all connecting wiring.

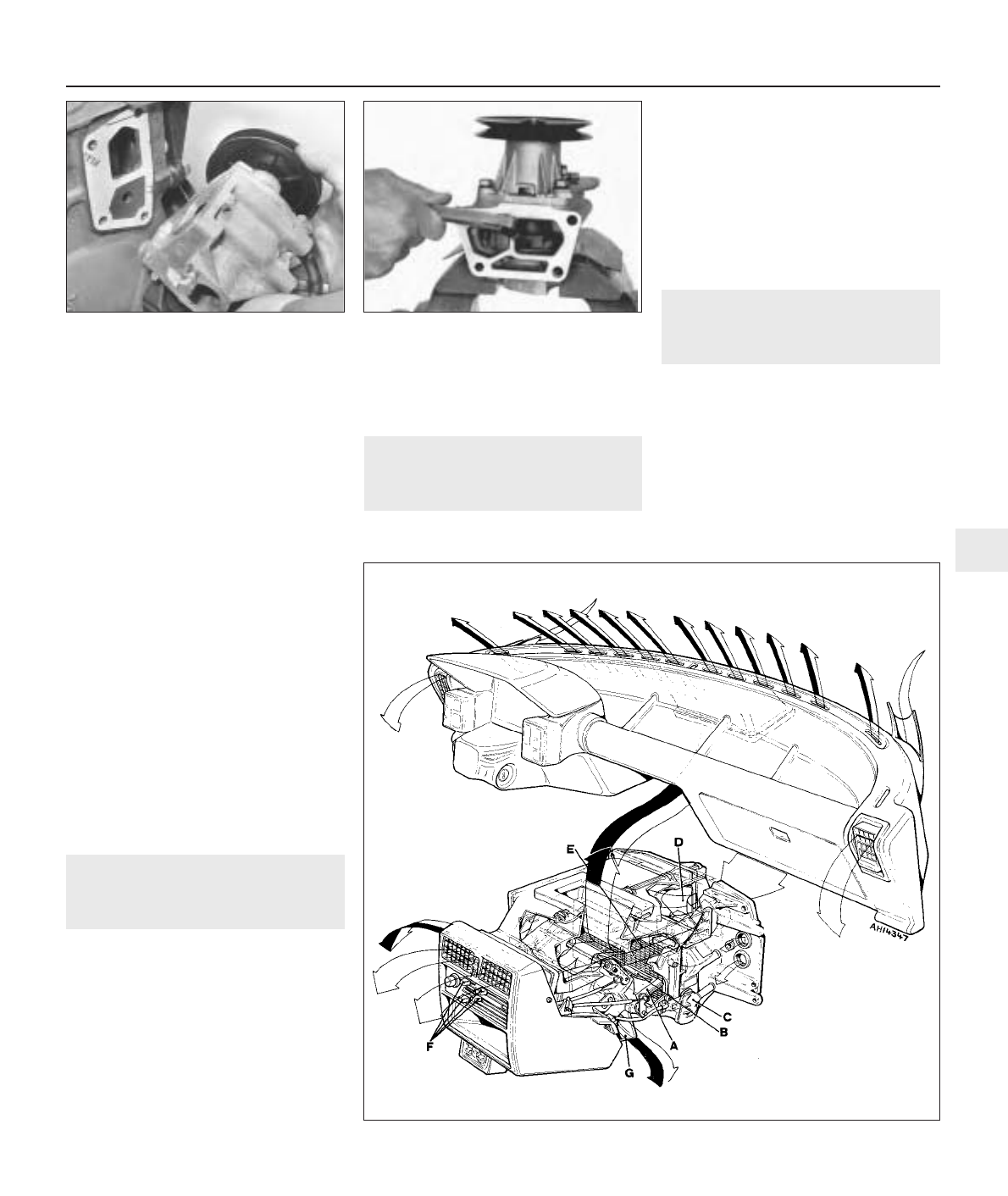

11 Heating and ventilation

system - description

1 The heater is centrally mounted under the

facia and is of fresh air type.

2 Air is drawn in through the grille at the base

of the windscreen. It then passes through the

coolant heated matrix when it can then be

distributed through selective outlets

according to the setting of the control levers.

3 A booster fan is provided for use when the

car is stationary or is travelling too slowly to

provide sufficient air ram effect.

4 Fresh air outlets are provided at each end

and centrally on the facia panel.

12 Heater unit -

removal and refitting

1

1 Drain the cooling system.

2 Disconnect the heater hoses at the engine

compartment rear bulkhead.

3 Working within the car under the facia

panel, disconnect the leads from the

heater blower by pulling the connecting plug

apart.

4 If a radio is fitted, disconnect the

aerial, earth, speaker and power leads from

it.

Cooling and heating systems 2•5

Fig. 2.6 Checking impeller clearance

(Sec 9)

9.21 Fitting coolant pump (1116 cc engine)

Fig. 2.7 Heater and ventilation system (Sec 11)

A Fresh air inlet flap

B Air distribution flap

C Coolant valve

D Blower

E Matrix

F Control levers

G Footwell air duct

2