75 If the pump is unworn, refit the rear cover

plate and tighten the screws fully.

76 Apply air pressure from a tyre pump to the

oil pump oil ducts to clear any sludge or other

material and then prime the pump by pouring

clean engine oil into its intake duct at the

same time turning the oil pump inner gear with

the fingers.

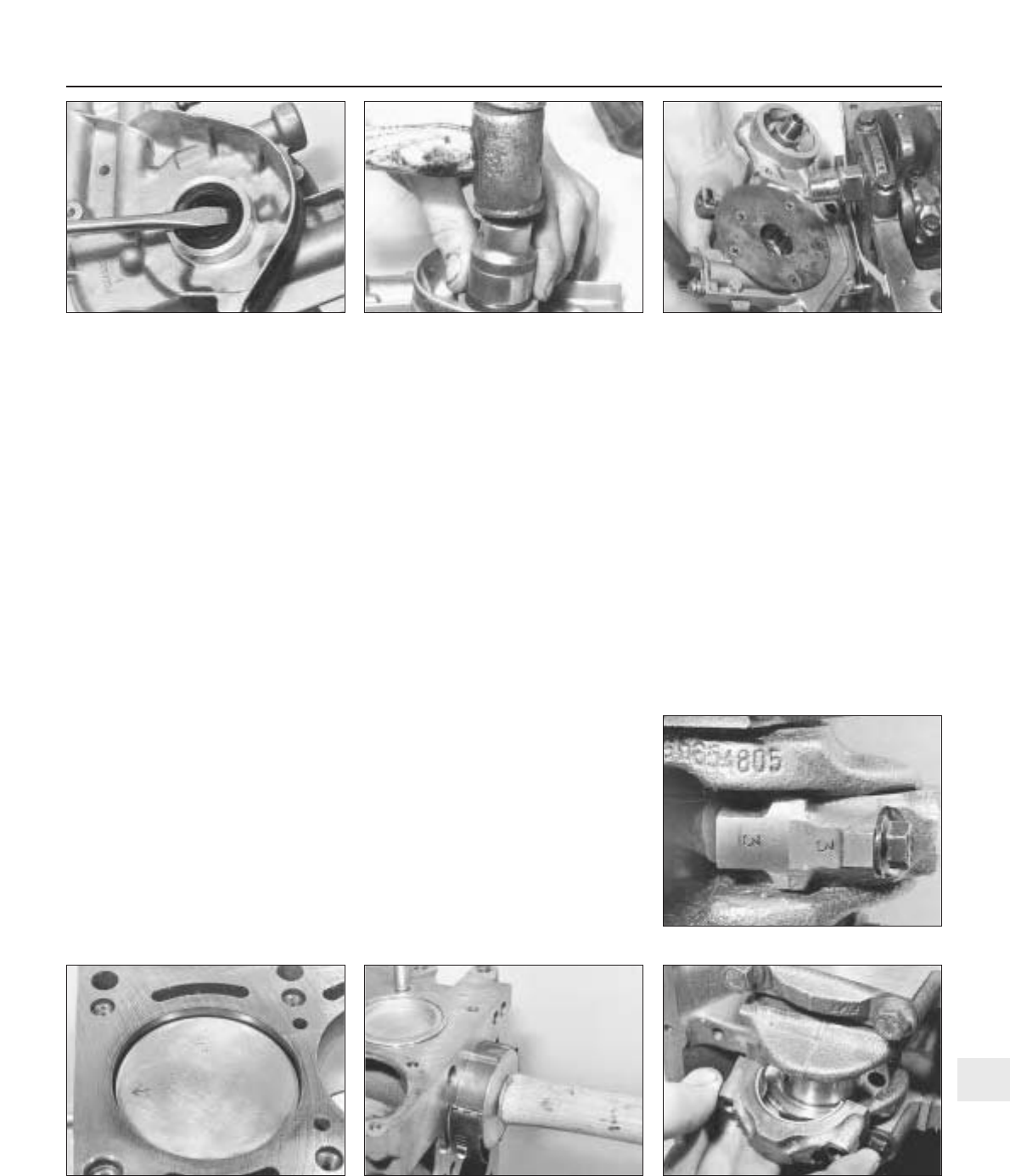

77 Lever out the oil seal and drive a new one

squarely into the oil pump casing (photos).

Lubricate the oil seal lips.

78 Bolt the pump into position using a new

joint gasket. Note one bolt is longer than the

others (photo).

79 Bolt on the oil pick-up assembly using a

new sealing washer.

80 Fit the crankshaft sprocket and tighten the

bolt to specified torque.

81 Fit and tension the timing belt.

82 Fit the sump pan. Screw on a new oil filter

cartridge. Wait for the specified period of time

(one hour) and then fill the engine with oil.

83 Run the engine for a few minutes, then

check and top up the oil level.

Pistons/connecting rods -

removal and refitting #

84 Remove the sump pan.

85 Unbolt and remove the oil pump

pick-up/filter screen assembly.

86 The big-end bearing shells can be

renewed without having to remove the

cylinder head if the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,

however, the main bearing shells will almost

certainly be worn as well, necessitating a

complete overhaul, including crankshaft

removal.

87 To remove the piston/connecting rods,

the cylinder head must be removed.

88 The big-end caps and their connecting

rods are numbered 1, 2, 3 and 4 from the

timing cover end of the engine. The numbers

are located either side of the rod/cap joint on

the engine oil dipstick tube side (photo).

89 Turn the crankshaft as necessary to bring

the first connecting rod big-end crankpin to its

lowest point, then unscrew the cap bolts and

remove the cap and shell bearing.

90 Push the connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal, or break the

piston rings during the attempt.

91 Remove the remaining piston/connecting

rods in a similar way. If the bearing shells are

to be used again, tape them to their

respective caps or rods.

92 Removal of the piston rings and

separation of the piston from the connecting

rod is covered in the next sub-Section.

93 Fit the bearing shells into the connecting

rods and caps, ensuring that the recesses into

which the shells seat are clean and dry.

94 Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.

95 Fit a piston ring clamp to compress the

rings, oiling the rings and the clamp interior

surfaces liberally.

96 Insert the first piston/connecting rod into

its cylinder bore. Make sure that the assembly

is the correct one for its particular bore. The

cap and rod matching numbers must be

towards the engine oil dipstick guide tube and

the arrow on the piston crown towards the

timing belt (photo).

97 Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

98 Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Check that the bearing shells are still in

position, then fit the big-end cap and bolts;

check that the cap is the right way round

(photo).

Supplement: Revisions and information on later models 13•25

5B.78 Fitting the oil pump5B.77B Using a socket to fit the new oil

pump oil seal

5B.77A Removing the oil pump seal

5B.98 Fitting a big-end bearing cap

5B.88 Connecting rod and cap numbers

5B.97 Fitting a piston/connecting rod5B.96 Piston directional arrow

13