2 The big-end bearing shells can be renewed

without having to remove the cylinder head if

the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,

however, the main bearing shells will almost

certainly be worn as well. In this case, the

engine should be removed for complete

overhaul including crankshaft removal.

3 To remove the piston/connecting rods,

remove the cylinder head as described in

Section 29.

4 Grip the oil pick-up pipe and twist or rock it

from its hole in the crankcase. It is an

interference fit in the hole.

5 Unscrew the nuts from the big-end caps,

then remove the caps with their bearing

shells. The caps and their connecting rods are

numbered 1, 2, 3 and 4 from the timing cover

end of the engine. The numbers are adjacent

at the big-end cap joint and on the side of the

crankcase furthest from the auxiliary shaft.

6 If the bearing shells are to be used again,

tape them to their respective big-end caps.

7 Push each connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal or break the piston

rings during the attempt.

8 If the connecting rod bearing shells are to

be used again, tape the shells to their

respective rods.

9 Dismantling the piston/connecting rod is

described in Section 18.

Refitting

10 Fit the new shells into the connecting rod

and caps, ensuring the surfaces on which the

shells seat, are clean and dry.

11 Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.

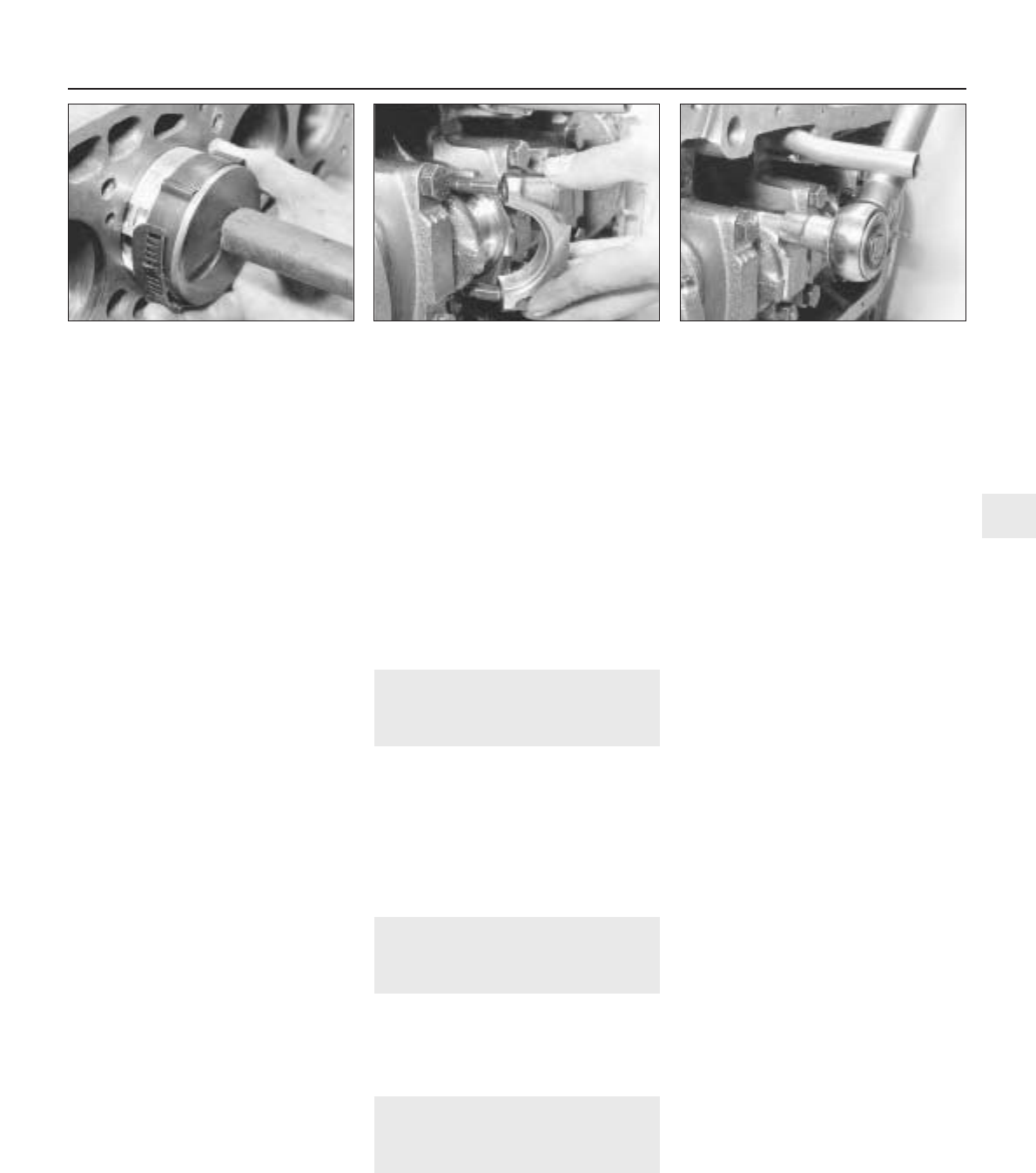

12 Fit a piston ring clamp to compress the

rings.

13 Insert the piston/connecting rod into the

cylinder bore, checking that the rod assembly

is correct for that particular bore. The cap and

rod matching numbers must be furthest away

from the auxiliary shaft (Fig. 1.31).

14 Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

15 Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Fit the big-end cap and nuts, checking that

the cap is the right way round (photo).

16 Tighten the big-end nuts to the specified

torque. The correct torque is important as the

nuts have no locking arrangement. After

tightening each big-end, check the crankshaft

rotates smoothly (photo).

17 Refit the oil pick-up pipe, the cylinder

head, oil pump and sump pan, all as

described earlier.

18 Refill the engine with oil and coolant.

33 Engine mountings -

renewal

1

1 Three engine/transmission flexible

mountings are used.

2 To renew a mounting, support the weight of

the engine/transmission on a hoist or jack and

unbolt and remove the mounting.

3 In the unlikely event of all three mountings

requiring renewal at the same time, only

disconnect them and renew them one at a

time.

34 Engine - method of removal

1 The engine complete with transmission

should be removed by lowering it to the floor

and withdrawing it from under the front of the

car which will have been raised to provide

adequate clearance.

35 Engine/transmission -

removal and separation

3

1 Open the bonnet, disconnect the

windscreen washer tube.

2 Mark the hinge positions on the underside

of the bonnet and then with the help of an

assistant to support its weight unbolt and

remove the bonnet to a safe place.

3 Disconnect the battery negative lead.

4 Drain the cooling system and the engine

and transmission oils.

5 Remove the air cleaner.

6 From the rear of the alternator disconnect

the electrical leads.

7 Disconnect the leads from the starter

motor, oil pressure and coolant temperature

switches, also the oil temperature switch.

8 Disconnect the LT lead from the distributor

and the HT lead from the ignition coil.

9 Disconnect the clutch cable from the

release lever at the transmission. Also

disconnect the speedometer drive cable

(knurled ring).

10 Pull the leads from the reversing lamp

switch.

11 Disconnect all coolant hoses from the

engine. Also disconnect the brake servo hose

from the intake manifold.

12 Disconnect the choke and throttle

controls from the carburettor.

13 Disconnect the inlet hose from the fuel

pump and plug the hose.

14 Disconnect the fuel return hose from the

carburettor.

15 Disconnect the coolant hoses from the

carburettor throttle block.

16 Raise the front of the car and remove the

front roadwheels.

17 Unscrew and remove the driveshaft to

hub nuts. These are very tight and a long

knuckle bar will be required when unscrewing

them. Have an assistant apply the brake pedal

hard to prevent the hub from turning.

18 Working under the car, remove the inner

wing protective shields and then disconnect

the exhaust downpipe from the manifold.

19 Disconnect the exhaust pipe sections by

removing the socket clamp just forward of the

rear axle beam. Remove the front section.

20 Disconnect the forward ends of the

gearchange rods by prising their sockets from

the ballstuds.

21 Unscrew the nuts on the steering tie-rod

end balljoints and then using a suitable

“splitter” tool, separate the balljoints from the

steering arms.

22 Unbolt the front brake hose support clips

1116 cc and 1301 cc engine 1•27

32.16 Tightening a big-end cap nut32.15 Fitting a big-end cap32.14 Fitting piston into cylinder bore

1