Door closure sensor

117 The sensor consists of a microswitch

within the lock. The switch actuates the

warning lamp according to whether the lock is

in the open or closed mode.

Check control system sensors -

testing

Brake fluid level sensor

118 With the fluid level correct, switch on the

ignition and depress the centre of the

reservoir cap. If the sensor switches are

working correctly, then “FAULT” should be

indicated on the check panel.

Coolant level sensor

119 With the coolant level in the expansion

tank correct, switch on the ignition and then

pull the wiring plug from the sensor. “FAULT”

should be indicated on the check panel. If it is

not, then it is the panel which is faulty.

120 An ohmmeter should be used to check

for continuity, holding the float in both the full

and low level positions.

Engine oil level sensor

121 With the oil level correct, disconnect the

wiring plug from the dipstick, and then bridge

the plug terminals (not dipstick side) with a 12

ohm resistor. Switch on the ignition.

122 If the red light on the check panel goes

out, then the fault is due to the sensor.

123 If the light stays on, then it is the check

panel module which is faulty.

Door closure sensor

124 Any fault in the lock microswitch can best

be detected using an ohmmeter.

16 Suspension

Front anti-roll bar -

removal and refitting ™

1 A front anti-roll bar is fitted to the 1301 cc,

1372 cc ie and 1372 cc Turbo ie engined

models. Removal of the bar on all models is

as follows. Firstly loosen off the front

roadwheel bolts, then raise the front of the

car, securely support it on axle stands and

remove the front roadwheels.

2 Disconnect the two gearchange rods from

the transmission.

3 Unbolt and disconnect the anti-roll bar

insulating clamps from the floorpan (photo).

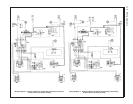

4 Unbolt the end links from the track control

arms and withdraw the anti-roll bar (photo).

5 Refitting is a reversal of removal, but only

tighten the nuts and bolts to the specified

torque with the car parked on level ground,

with four passengers and 40 kg of luggage

inside.

Suspension strut - later models

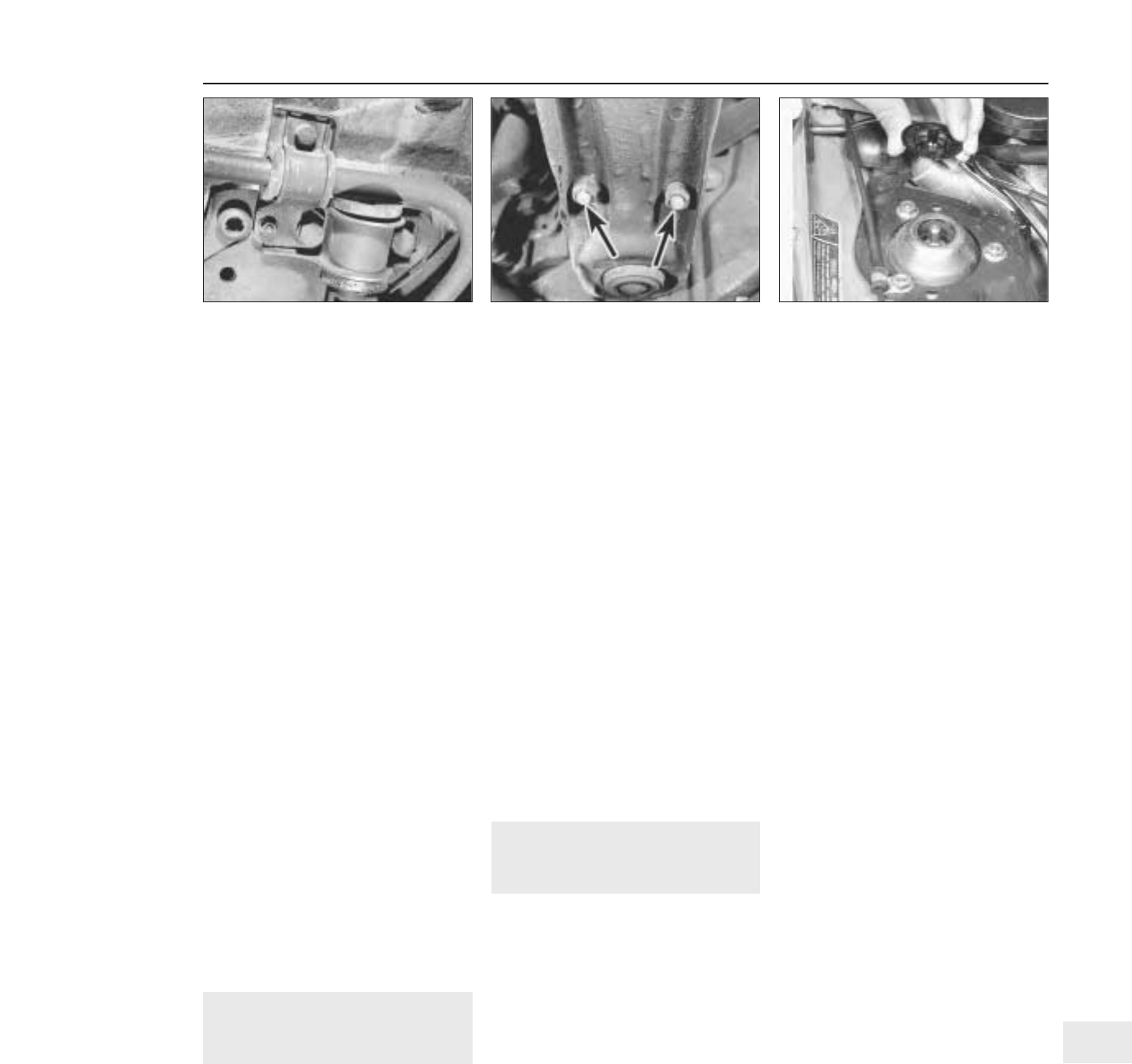

6 The suspension strut upper mounting nuts

on later models also secure the brackets for

the mounting of ancillary components such as

the fuel filter, fuel system relays and fuses,

etc. (depending on model).

7 When removing the suspension strut units,

it will therefore be necessary to detach and

support these brackets and their fittings

(photo).

17 Bodywork

Plastic components

1 With the use of more and more plastic

body components by the vehicle

manufacturers (e.g. bumpers, spoilers, and in

some cases major body panels), rectification

of more serious damage to such items has

become a matter of either entrusting repair

work to a specialist in this field, or renewing

complete components. Repair of such

damage by the DIY owner is not really

feasible owing to the cost of the equipment

and materials required for effecting such

repairs. The basic technique involves making

a groove along the line of the crack in the

plastic using a rotary burr in a power drill. The

damaged part is then welded back together

by using a hot air gun to heat up and fuse a

plastic filler rod into the groove. Any excess

plastic is then removed and the area rubbed

down to a smooth finish. It is important that a

filler rod of the correct plastic is used, as

body components can be made of a variety

of different types (e.g. polycarbonate, ABS,

polypropylene). Damage of a less serious

nature (abrasions, minor cracks, etc.) can be

repaired by the DIY owner using a two-part

epoxy filler repair material. Once mixed in

equal proportions, this is used in similar

fashion to the bodywork filler used on metal

panels. The filler is usually cured in twenty to

thirty minutes, ready for sanding and

painting.

2 If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will be left with the

problem of finding a suitable paint for

finishing which is compatible with the type of

plastic used. At one time the use of a

universal paint was not possible owing to the

complex range of plastics encountered in

body component applications. Standard

paints, generally speaking, will not bond to

plastic or rubber satisfactorily. However, it is

now possible to obtain a plastic body parts

finishing kit which consists of a pre-primer

treatment, a primer and coloured top coat.

Full instructions are normally supplied with a

kit, but basically the method of use is to first

apply the pre-primer to the component

concerned and allow it to dry for up to

30 minutes. Then the primer is applied and

left to dry for about an hour before finally

applying the special coloured top coat. The

result is a correctly coloured component

where the paint will flex with the plastic or

rubber, a property that standard paint does

not normally possess.

Rear view mirrors ¡

Interior

3 The mirror is of safety type, “breaking” off

its ball fixing upon impact from a front seat

occupant.

4 To remove the mirror, grip the head and

Supplement: Revisions and information on later models 13•111

16.7 Suspension strut upper mounting

nuts, showing bracket and cable clip on

the 1372 cc ie model

16.4 Anti-roll bar fixing nuts (arrowed)16.3 Anti-roll bar clamp

13