protective shield to gain access to the pump

which is located forward of the fuel tank.

60 Disconnect the fuel hoses and the wiring

connector, release the retaining clamp and

withdraw the pump unit.

Refitting all components

61 Refitting of all components is a reversal of

the removal procedure, but note the following

specific points.

62 Ensure that all components are clean prior

to refitting and where applicable, use new

seals and gaskets. Ensure that all connections

are securely and correctly made.

63 Do not reconnect the battery until all the

refitting procedures are complete.

64 When the engine is restarted, check

around the fuel injection system for any signs

of leakage from the fuel supply and return

components.

Lambda sensor - general

65 The sensor is screwed into the exhaust in

front of the catalytic converter.

66 A faulty sensor can damage the converter,

therefore it must be checked regularly (see

Maintenance schedule, Section 3) by a dealer

using special equipment.

67 Use of leaded fuel will also damage this

sensor, as well the converter.

PART F:

TURBOCHARGER SYSTEM

Description

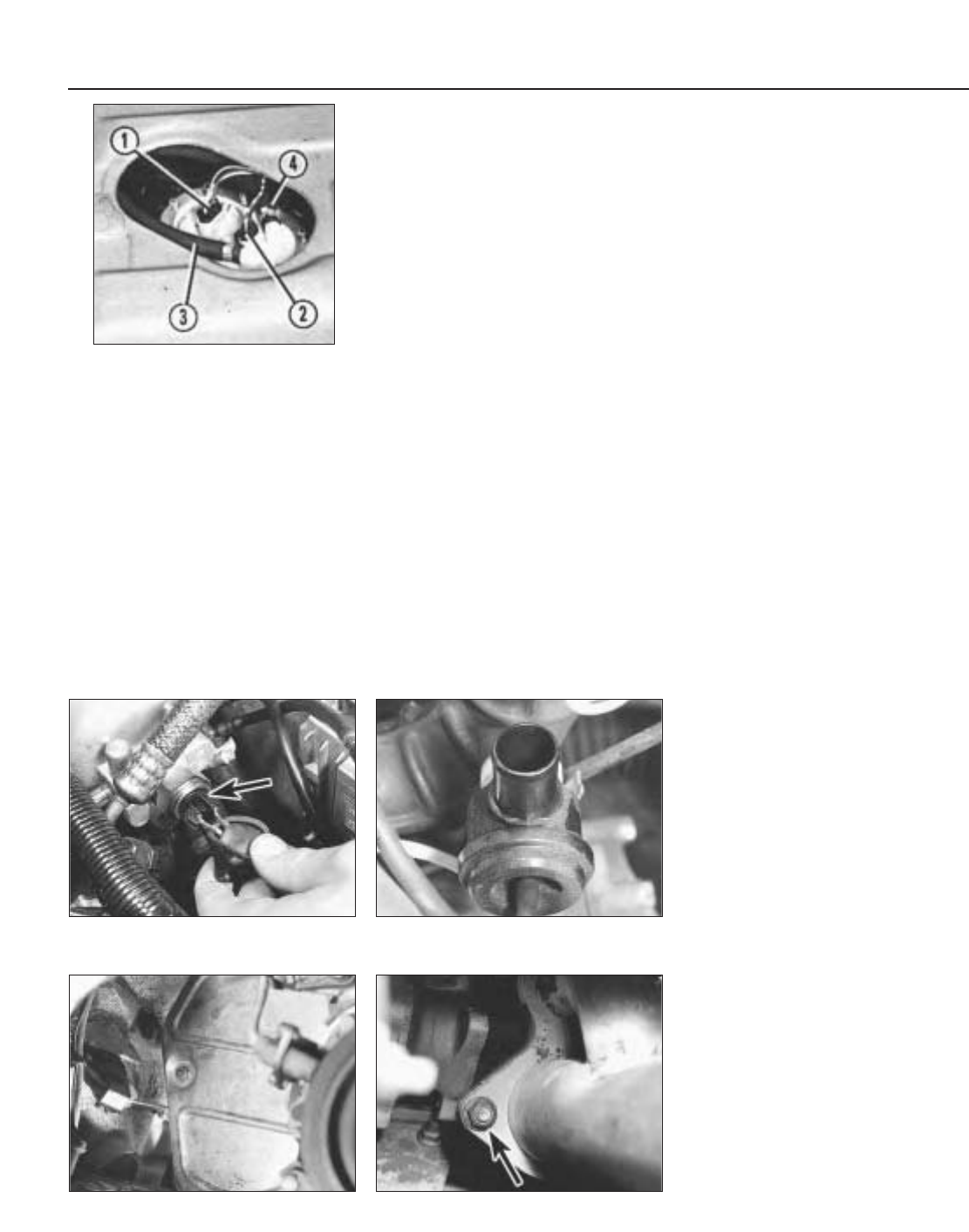

1 A turbocharger is fitted to certain 1301 and

1372 cc ie engines. The accompanying

photographs are all taken from a 1301 cc

engine, but the system is much the same for

both engine types.

2 The turbocharger is basically a shaft with an

exhaust gas-driven turbine at one end, and a

compressor located at the other end which

draws in outside air and forces it into the inlet

manifold. By compressing the incoming air, a

larger charge can be let into each cylinder,

and greater power output is achieved than

with normal aspiration.

3 Lubrication of the turbocharger shaft

bearings is provided by pressurised engine

oil, and the unit is cooled by the coolant from

the engine cooling system.

4 A wastegate valve is incorporated in the

turbocharger to divert excessive exhaust gas

pressure from the turbine into the exhaust

pipe at a predetermined pressure level.

5 A maximum air pressure switch is located in

the inlet manifold. Its purpose is to cut the

ignition system off when the turbocharger

system pressure continues to increase

beyond 0.86 bars (12.5 lbf/in

2

). This would

otherwise damage the engine, due to high

combustion temperatures and pressures

(photo).

6 An intercooler (heat exchanger) is located

between the turbocharger and the inlet

manifold. Its function is to cool the inlet

charge, thus increasing its density, to provide

greater power output.

7 A mechanical bypass valve is located

between the low-pressure pipe (downstream)

and the high-pressure pipe (upstream), which

reduces the inherent noise from the

turbocharger when the accelerator pedal is

released (photo).

8 None of the components of the

turbocharger system can be repaired and

parts are not available. Any fault will therefore

mean that the turbocharger or associated

assemblies will have to be renewed complete.

Precautions

9 The following precautions should be

observed when using a turbocharged vehicle.

a) Never operate the engine without the air

cleaner fitted.

b) Never switch off the engine before its

speed has dropped to idling. If the car

has been driven hard, allow it to idle for a

few minutes before switching off. Failure

to observe these recommendations can

cause damage to the turbocharger due to

lack of lubrication.

10 Always keep the fuel injection system

well-maintained and tuned. Operating on a

weak mixture can cause overheating of the

turbocharger.

Turbocharger

(1301 cc ie engine) -

removal and refitting ¡

11 Disconnect and remove the airflow meter

as described in Section 9C.

12 Disconnect the spiral-wound hose from

the fuel injector cooling duct.

13 Remove the turbocharger air hoses from

within the left-hand side of the engine

compartment. Note particularly their routing.

14 Remove the throttle housing/inlet

manifold as described in Section 9C, also the

fuel rail, injectors and inlet manifold branch

pipe stubs. Remove the alternator heat shield

(photo).

15 Remove the exhaust heat shield.

16 Unscrew the turbocharger-to-exhaust

pipe flange nuts (photos).

13•82 Supplement: Revisions and information on later models

9F.16A Turbocharger-to-exhaust flange

nut (arrowed)

9F.14 Alternator heat shield

9F.7 Bypass valve9F.5 Maximum air pressure switch

(arrowed)

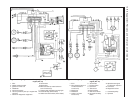

Fig. 13.63 Fuel pump and sender unit

location on the 1372 cc Turbo ie engine

(Sec 9E)

1 Fuel level gauge sender connector

2 Fuel pump connector

3 Fuel return hose

4 Fuel supply hose