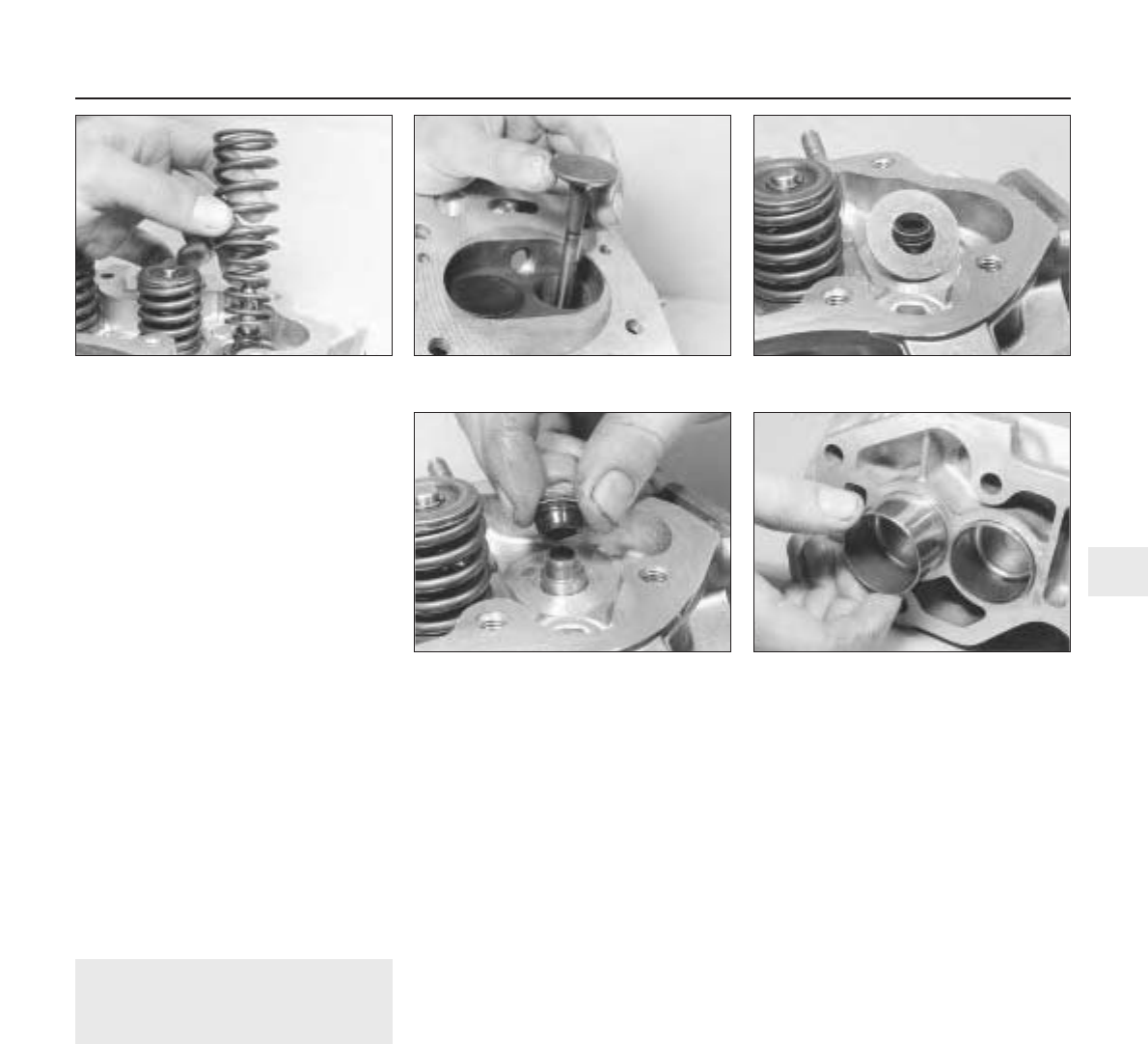

6 Remove the spring seat (photo).

7 Discard the valve stem oil seal and fit a new

one (photo).

8 Remove the remaining valves in a similar

way and keep the components in their

originally fitted sequence.

9 Reassembly is a reversal of removal. Refit

the components to their original positions, but

renew the valve springs if their free length is

less than that of a new spring or if the

springs have been in operation for more than

80 000 km (50 000 miles).

10 The original valve clearance adjusting

shims will no longer provide the correct

clearances if the valves have been ground in

or the seats recut. Only where dismantling of

a valve was carried out to renew a spring is

there any purpose in returning the shims to

their original locations. Try to obtain the loan

of eight thin shims from your dealer and insert

them into the tappets (cam followers) before

assembling the cam followers to the carrier,

where they should be retained with thick

grease (photo).

11 Fit the camshaft carrier, complete with

cam followers and shims to the cylinder head.

12 Adjust the valve clearances as described

in Section 26.

40 Examination and renovation

4

1 The procedures are similar to those

described in Section 18 covering the

following:

Cylinder block and crankcase

Crankshaft and bearings

Pistons and piston rings

Flywheel

2 The following additional items must also be

examined.

Oil pump

3 Carefully, clamp the pump housing in a

vice, shaft downwards.

4 Take off the pump cover, with the suction

pipe. This will release the oil pressure relief

valve inside. Also inside is a filter.

5 Remove the internal cover plate.

6 Take out the driveshaft and the gears.

7 Clean and examine all the parts. Measure

the clearances against the Specifications. The

end clearance is measured by putting a

straight-edge across the cover face.

8 The oil pump should only need

replacements after very long mileage, when

the rest of the engine is showing great signs

of wear.

9 The length of a new gear can be measured

against the old gear to see if a new gear will

restore the end clearance to the Specifica-

tions. Otherwise the housing must be

changed.

10 The driven gear shaft is mounted in the

housing with an interference fit. If there is any

slackness, a new housing (which will come

with shaft fitted) must be used.

11 The oil pump shares its drive with the

distributor.

Camshaft, cam followers and

shims

12 The camshaft journals and cams should

be smooth, without grooves or scores.

13 Wear in the camshaft carrier bearings can

only be rectified by renewal of the carrier.

14 Cam follower wear is usually very small

and when they show slackness in their bores,

it is probably the light alloy of the camshaft

carrier which has worn.

15 Always measure the thickness of the valve

clearance shims using a metric micrometer.

Any grooving or wear marks in the shims

should be rectified by renewal with ones of

similar thickness.

Auxiliary shaft

16 The shaft journals, the fuel pump

eccentric, and the drivegear for the distributor

and oil pump should be smooth and shiny. If

not, the shaft will have to be renewed.

17 The bushes should still be tight in the

cylinder block, their oil holes lined up with

those in the block.

18 Measure the bearing clearance. If

excessive, the bushes will have to be

renewed. They are a press fit, and require

reaming with a special reamer after fitting.

This is a job best done by a Fiat agent with the

special tools.

19 Ensure the new bushes are fitted with the

oil holes lined up.

20 Also check the driven gear and its bush.

21 It is recommended a new oil seal is fitted

in the endplate. Hold the shaft in a vice, and

remove the pulley. Fit the new oil seal in the

endplate, lips inwards.

Timing belt tensioner

22 Check the bearing revolves smoothly and

freely, and has no play. Do not immerse it in

cleaning fluid, as it is partially sealed. Wipe

the outside, and then smear in some new

general purpose grease.

23 The action of the spring will have been felt

when the belt was taken off. It should be

cleaned, and oiled, to prevent seizure through

dirt and rust.

24 Note the circlip on the engine right-hand

mounting bracket. This retains the timing belt

tensioner plunger.

1116 cc and 1301 cc engine 1•29

39.6 Valve spring seat39.5 Removing a valve39.4B Double valve springs

39.10 Cam followers fitted to camshaft

carrier

39.7 Valve stem oil seal

1