removal are in place under the

engine-to-gearbox bolts. Do not allow the

weight of the gearbox to hang on the input

shaft as it is engaged with the clutch friction

disc.

29 Refit the starter motor, ensuring that the

wiring harness bracket is in position on the

top bolt.

30 Locate the engine/transmission unit at the

front of the car and move it into position under

the engine compartment. Attach the lifting

sling and hoist as during removal.

31 Enlist the aid of an assistant to help

steady the combined units as they are raised

into position and to locate the mountings in

the engine compartment.

32 Once they are located, tighten the

mountings to the specified torque settings,

then disconnect the lifting hoist and sling.

33 The remainder of the refitting and

reconnection procedures are a reversal of the

removal procedure described in Part C. For

further details on reconnecting the

suspension and driveshaft components,

refer to Chapter 7 and Section 13 of this

Chapter.

34 Ensure that the exhaust downpipe-to-

manifold connection is clean and renew the

gasket when reconnecting this joint. Use a

smear of exhaust assembly paste on the joint

faces. Use new lockwashers and tighten the

flange nuts securely.

35 Ensure that all fuel and coolant

connections are cleanly and securely made.

36 Ensure that all wiring connections are

correct and securely made.

37 Top up the engine and transmission oil

levels.

38 Refill the cooling system.

39 Check that all connections are securely

made, then reconnect the battery negative

lead.

Initial start-up after major

overhaul

40 Refer to Chapter 1, Section 45.

8 Cooling system

PART A:

999 AND 1108 CC ENGINES

Description

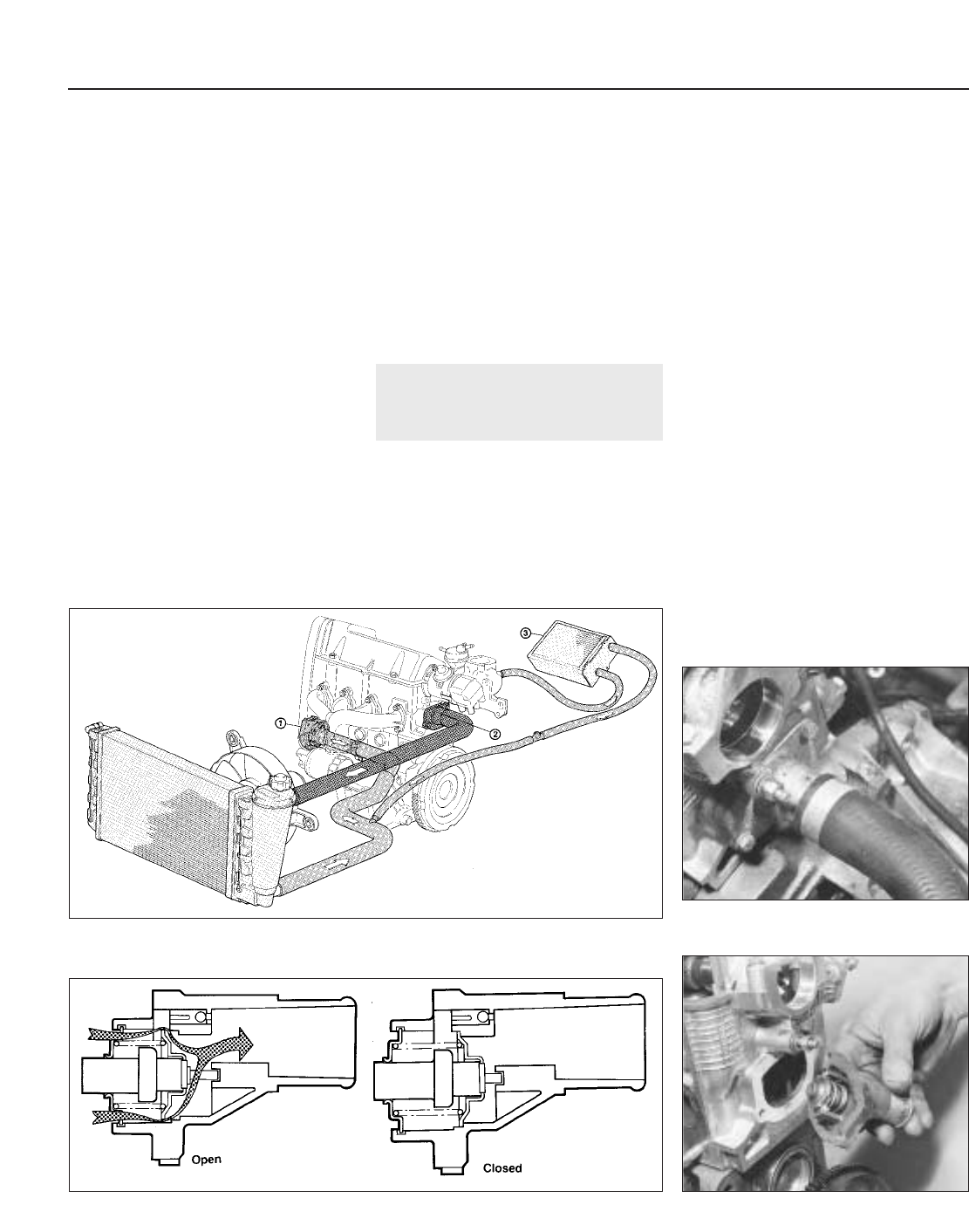

1 The operation and function of the cooling

system is essentially as described in Chapter

2 but note the location of the various

components and the routing of the coolant

hoses in Fig. 13.26.

Maintenance

2 Topping-up, draining and refilling

procedures are as for 1116 and 1301 cc

engines in Chapter 2, but note that the

coolant capacity is different (see Specifica-

tions).

Thermostat -

removal and refitting ¡

3 The thermostat is located on the left-hand

end of the cylinder head, below the

distributor.

4 The thermostat cannot be renewed

independently of its housing and if faulty the

complete assembly must be renewed.

5 Drain the cooling system.

6 Although the thermostat housing can be

removed directly from the cylinder head,

better access is provided if the distributor is

first withdrawn as described in Section 10 of

this Chapter (photo).

7 Disconnect the coolant hose from the

thermostat housing and unscrew the housing

flange bolts. Remove the assembly. Note that

it may be necessary to tap it free with a

plastic-faced or wooden mallet if stuck in

place.

8 Remove the gasket and clean the mating

surfaces.

9 Use a new gasket and bolt the assembly

into position (photo).

10 Reconnect the coolant hose, then fill and

bleed the cooling system.

13•54 Supplement: Revisions and information on later models

Fig. 13.26 Cooling system circuit - 999 and 1108 cc engines (Sec 8A)

1 Coolant pump 2 Thermostat 3 Heater matrix

Fig. 13.27 Cooling system thermostat in open and closed positions - 999 and 1108 cc

engines (Sec 8A)

8A.9 Fitting the thermostat housing. Note

the new gasket

8A.6 The thermostat housing (shown with

distributor removal) on the 999 cc engine