crankcase. If the shells are to be used again,

keep them with their respective bearing caps.

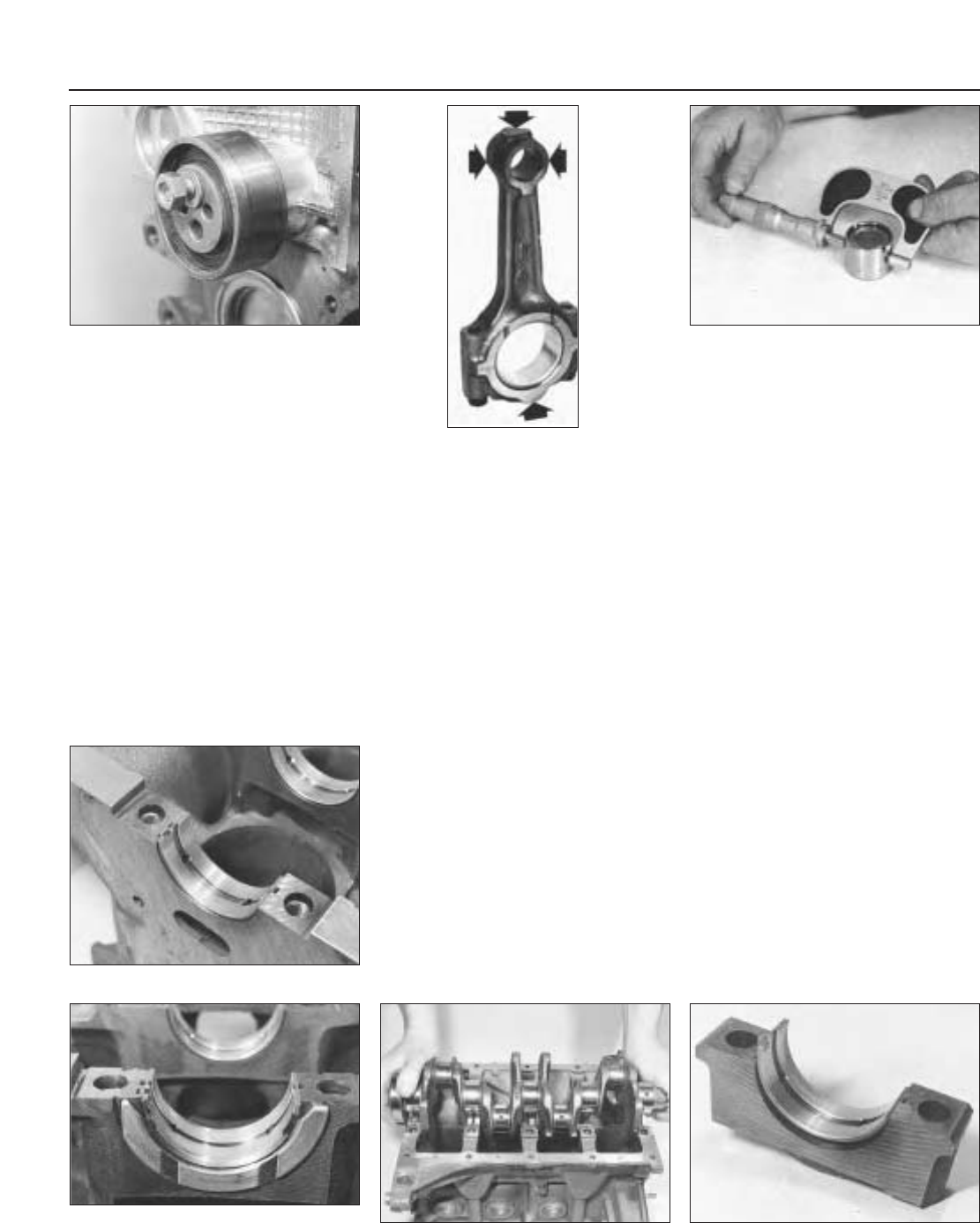

70 The thrust washers which control

crankshaft endfloat are located in the

crankcase, and retained by the turned-over

edges of the centre main bearing shell.

71 The engine is now fully stripped.

Examination and renovation

72 The procedures for the following items are

essentially as described in Chapter 1, Sec-

tion 18.

Cylinder block and crankcase

Crankshaft and bearings

Flywheel

Oil seals and gaskets

Cylinder head

73 Using a straight-edge, check the cylinder

head gasket surface for distortion. If it

exceeds the specified tolerance, it must be

surface ground by your dealer.

74 Refer to Chapter 1, Section 39, for

dismantling and renovation operations. Note

that single valve springs are fitted.

Oil pump

75 Checking operations are described in

sub-Section B.

Pistons and connecting rods

76 Refer to sub-Section B.

77 If one or more connecting rods are

changed, it is important that its weight is

identical to that of the original. Use an

accurate balance to weigh them and remove

metal if necessary from the new rod in the

areas indicated in Fig. 13.7.

Camshaft and cam followers

78 If the camshaft journals or bearings show

any sign of wear or scoring, then the

camshaft, or cylinder head, or both must be

renewed.

79 The cam followers should be checked for

ovality using a micrometer. Unless unworn

they should be renewed.

Timing belt tensioner and timing belt

80 The tensioner is a lubricant-sealed pulley,

and it should be tested for smooth and quiet

operation by turning it with the fingers. Any

evidence of roughness or rattle will indicate

the need for a new assembly (photo).

81 The timing belt should be inspected at

regular intervals for correct adjustment and

condition (see Section 3 or “Routine

maintenance” at the beginning of the Manual).

If there is evidence of worn teeth, cracking or

fraying, or oil contamination, renew the belt.

The vehicle manufacturers recommend that

the belt is renewed whenever it is removed,

and it should certainly be renewed at the

intervals specified in Section 3 or the main

“Routine maintenance” section at the

beginning of this Manual as a precautionary

measure against belt breakage and

consequent expensive engine damage.

PART D:

ENGINE REASSEMBLY AND

REFITTING

Reassembly - general

1 Refer to Chapter 1, Section 19.

Complete reassembly #

2 With the cylinder block/crankcase standing

on the work surface, fit the bearing half shells

into their crankcase seats (photo). Make sure

that the seats are perfectly clean as dirt or grit

trapped under the shell will cause binding

when the crankshaft is turned.

3 The centre bearing crankcase web

incorporates the thrust washers held by the

lips of the bearing shell (photo).

4 Oil the shells and lower the crankshaft into

the crankcase (photo).

5 Fit the bearing shells into the main bearing

caps, again making sure that the shell seats

are perfectly clean (photo).

13•30 Supplement: Revisions and information on later models

5D.5 Main bearing cap and shell5D.4 Fitting the crankshaft

5D.3 Crankshaft thrust washer at centre

bearing

5D.2 Main bearing shell in crankcase

Fig. 13.8 Checking a cam follower for

ovality - 999 and 1108 cc engine (Sec 5C)

Fig. 13.7 Metal removing areas (arrowed)

on connecting rod - 999 and 1108 cc

engine (Sec 5C)

5C.80 Timing belt tensioner