5.2 Operator Diagnostics

This gate operator is designed with built-in diagnostics that will alert you to potential or existing

problems that the microprocessor has detected. Specific fault conditions are checked and the

operator will signal that a fault exist through the built-in alarm.

Constant tone is heard when power is applied:

• This indicates that the limit switch wire harness is not connected to the circuit board. In this

condition, the operator will not run and the tone will continue until the fault is corrected.

Check to be sure that the limit switch plug is properly inserted into P2.

Constant tone is heard:

• This indicates that the operator is in a hard shutdown condition (section 4.2). The tone will

continue to sound for five minutes, and then will beep once every five seconds. The

operator-reset button must be pressed or power must be removed and then reapplied to

return the operator to normal operation.

Short tone is heard every five seconds:

• This indicates that the operator has been in a hard shutdown condition in excess of five

minutes. This will continue until the operator-reset button is pressed or until power is

removed from the operator.

Operator runs for 1 second and stops, two short tones are heard:

• This indicates that there may be a fault with the current sensor circuit. Check that the red

current sensor wire has been passed through the hole in the current sensor donut with the

correct number of turns as shown in the table.

• NOTE: For 1 HP 3-phase operators only, the red current sensor wire is connected directly to

the spade lug opposite terminal 19 without passing through the current sensor donut. The

black motor wire is routed through the donut with the number of turns as shown in the table.

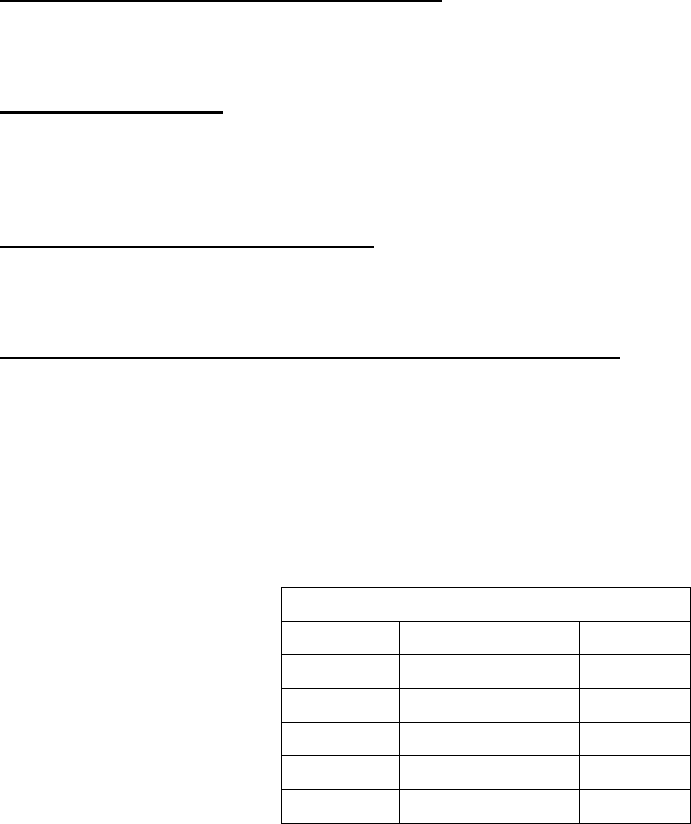

Current Sensor Donut

Motor Volt / Ph Turns

½ HP All 2

1 HP 115 / 208 / 230 1

Ø

1

1 HP 208 – 3

Ø

5

1 HP 230 – 3

Ø

5

1 HP 460 – 3

Ø

9

46