2.2 High Voltage Connections

Use Table 1 to determine high voltage wire size requirements. The distance shown in the chart is

measured in feet from the operator to the power source. If power wiring is greater than the maximum

distance shown, it is recommended that a service feeder be installed. A separate power disconnect

must be installed at the operator. The wire table is based on stranded copper wire. Wire run

calculations are based on a 3% voltage drop on the power line, plus an additional 10% reduction in

distance to allow for other losses in the system.

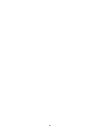

WIRE SIZE / DISTANCE IN FEET VOLTS HP AMPS

12 AWG 10 AWG 8 AWG 6 AWG

115 1/2 5.4 170 275 460 685

208 / 230 1/2 2.7 685 1100 1830 2750

460 1/2 1.4 2875 4600 7665 11500

115 1 9.7 95 155 250 385

208 / 230 – 3

Ø

1 2.8 660 1060 1765 2650

460 – 3

Ø

1 1.3 2980 4770 8000 11940

Table 1

• Route incoming high voltage power through

disconnect and into the operator.

SEE DETAIL

• Be sure wiring is installed in accordance with local

codes. Be sure to color code all wiring.

• Connect the power wires to the high voltage

terminal strip as shown.

• It is recommended that a surge suppresser be

installed on the high voltage power lines to help

protect the operator and circuit board from surges

and power fluctuations.

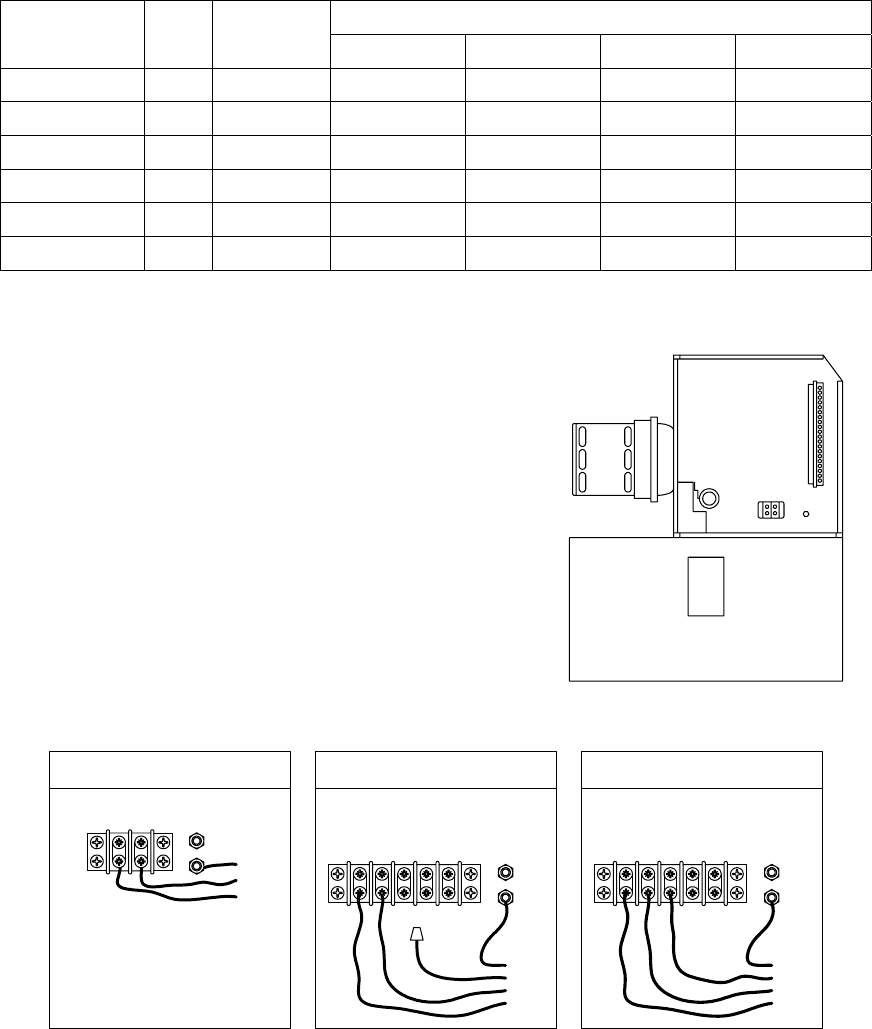

• If 3-Ph power is used to power a ½ HP unit, cap

off one leg of the power as shown below.

½ HP - High Voltage 3

Ø

Power

208/230/460

208/230/460

VAC 3 Ph

208/230/460

BLACK

BLACK

GREEN

BLACK

1 HP - High Voltage 3

Ø

Power

208/230/460

208/230/460

VAC 3 Ph

208/230/460

208/230/460

BLACK

BLACK

GREEN

BLACK

115 VAC

½ - 1 HP - 115 VAC Power

HOT

NEUT

BLACK

WHITE

GREEN

22