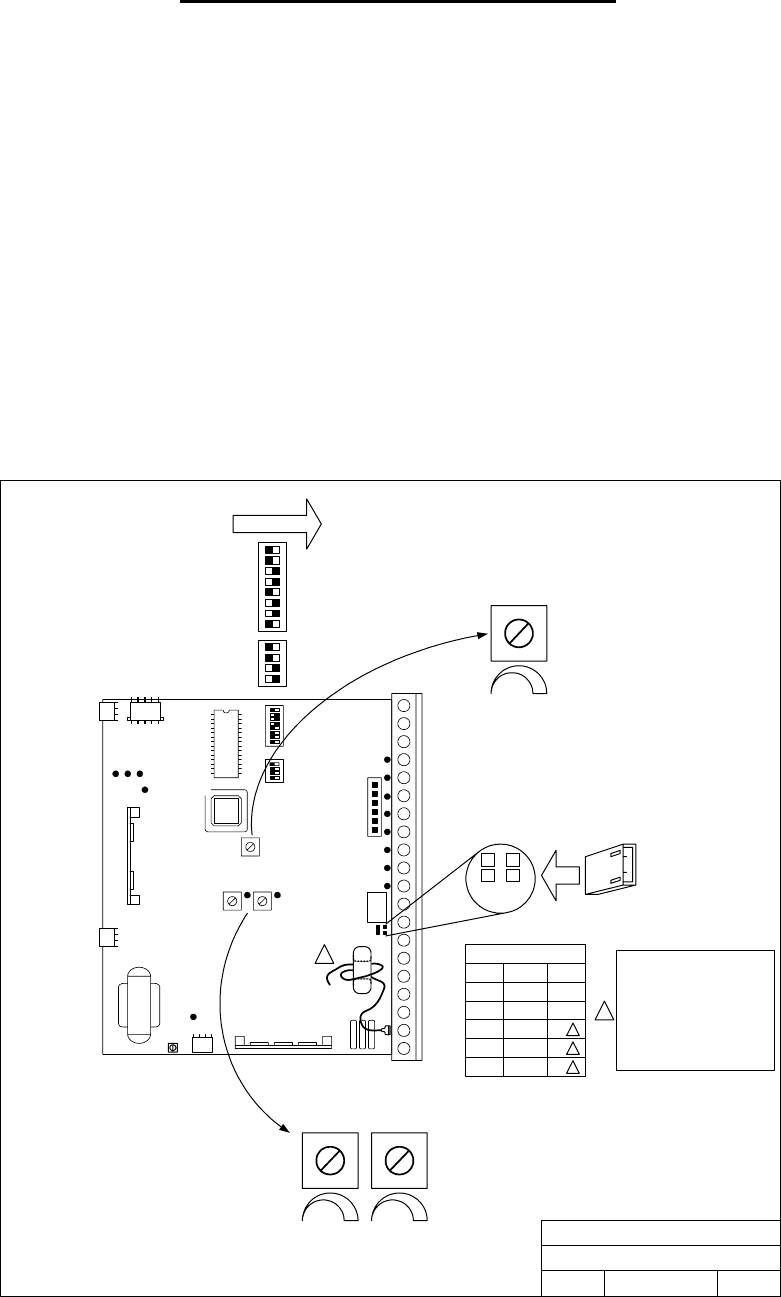

SECTION 3 - ADJUSTMENTS

The switch settings and adjustments in this chapter should be made after your installation and wiring

to the operator(s) is complete. Whenever any of the programming switches on the circuit board are

changed, power must be shut-off, and then turned back on for the new setting to take effect.

3.1 Circuit Board Adjustments

• Set the DIP-switches on the circuit board to the desired setting. See switch-setting charts in

section 3.2.

• Auto close timer (when turned on) can be set from 1 second (full counter clockwise) to

approximately 23 seconds (full clockwise).

• Dry contact relay (terminals 11-12) can be set for Normally Open (NO) or Normally Closed

(NC) operation by placing the relay shorting bar on the NO or NC pins respectively.

• Power LED indicates that low voltage power is applied to the circuit board. Input LEDs should

be OFF and will only illuminate when the input is activated. The limit LED will be ON when

the respective limit switch is activated.

Relay Contact Setting

NO - Relay Normally Open (factory)

NC - Relay Normally Closed

REVERSE SENSOR

MIN MAX

MIN MAX

CLOSE OPEN

1

2

3

4

1

2

3

4

5

6

7

8

SW1 SW2

ON

DOORKING, INC., INGLEWOOD, CA 90301

Title:

Date: Rev.Dwg. No.

4403 Control Board Adjustments

B

5/05 M9310-065-8

NC

NO

CAUTION

HIGH VOLTAGE

TIMER

MIN MAX

0 - 23 Seconds

SW1, Switch 4 ON

1

Current Sensor Donut

½ HP All 2

1 HP 115 / 1 1

Motor Volt/Ph Turns

1 HP 208 / 3 5

1

1 HP 230 / 3 5

1

1 HP 460 / 3 9

1

1

For 1 HP 3

Ø

motors, connect

red sensor wire directly to lug

opposite terminal 19. Route

black motor wire directly

through current sensor donut.

See wire diagram:

4403-1-202346-3

33