13. Tighten each wheel nut by turning it clockwise with

your hand until the wheel is held against the hub.

14. Lower the vehicle by turning the wheel wrench

counterclockwise. Lower the jack completely.

{ CAUTION:

Wheel nuts that are improperly or incorrectly

tightened can cause the wheels to become loose or

come off. The wheel nuts should be tightened with

a torque wrench to the proper torque specification

after replacing. Follow the torque specification

supplied by the aftermarket manufacturer when

using accessory locking wheel nuts. See Capacities

and Specifications on page 5-133 for original

equipment wheel nut torque specifications.

Notice: Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

specification. See Capacities and Specifications on

page 5-133 for the wheel nut torque specification.

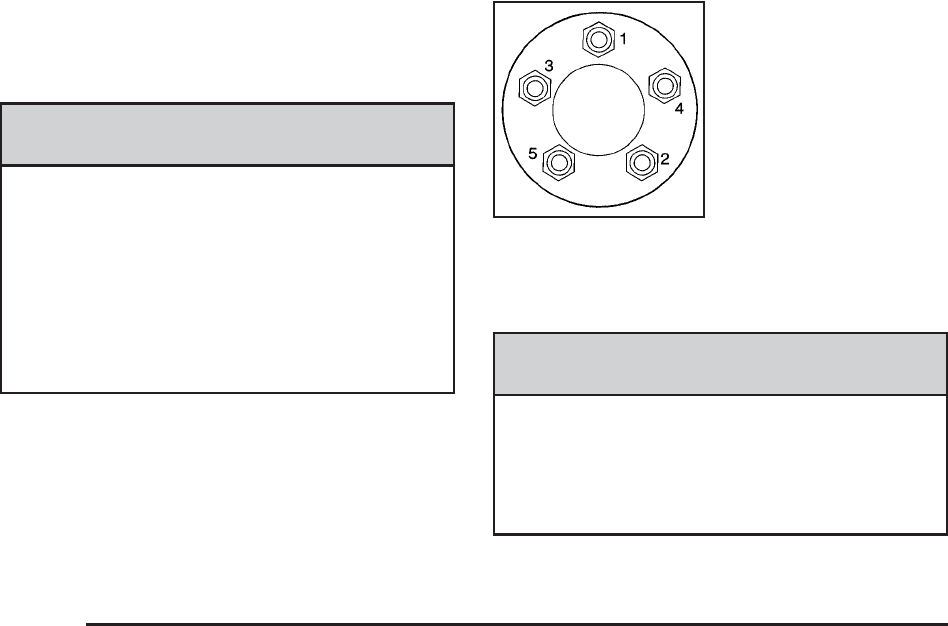

15. Tighten the wheel nuts

firmly in a crisscross

sequence as shown.

Storing a Flat or Spare Tire and

Tools

{ CAUTION:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision, loose

equipment could strike someone. Store all these in

the proper place.

5-106