7

above grade. Two 13/32 diameter holes will need to be drilled on

each side of the 4 x 4 tube. Center each pair of holes on the face of

the post 2-5/8” apart and 7/8” down from the top. Each pair of holes

is to align with the pre-drilled holes in the chassis mounting angles of

the RS4000. See Figure 6 for locating the post relative to the gate,

noting that the center of the output shaft is located 4 5/8” away from

the center of the post, or 2 5/8” away from the face of the 4 x 4 post.

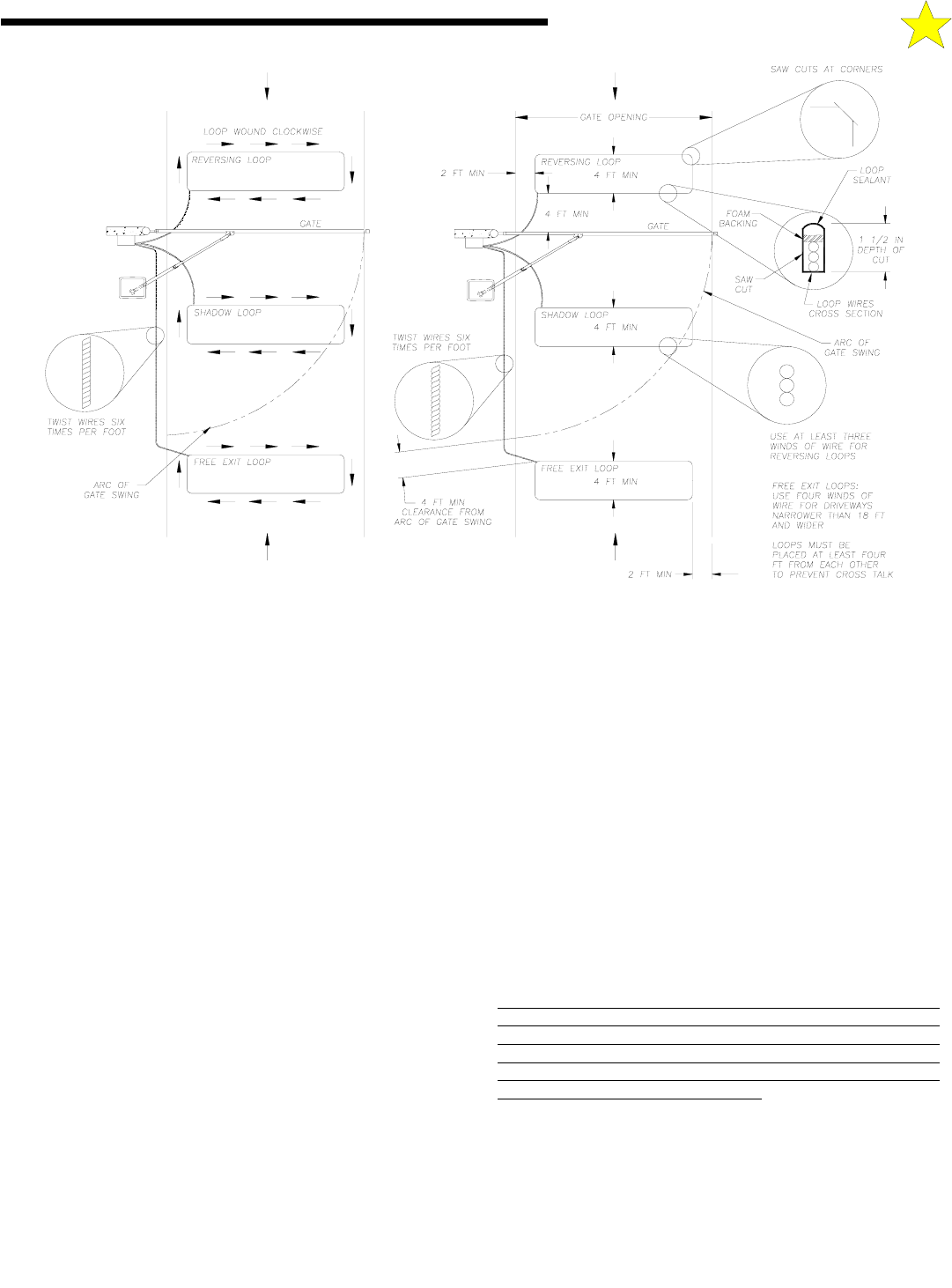

PLACING THE VEHICLE DETECTOR LOOPS

If vehicle detectors are to be used with the RS4000, the "loops" to be

buried in the drive should be installed during the site preparation

phase of the installation. Proper placement of the vehicle detector

wire loops is critical if the loops are to provide satisfactory, extended

service. THE MOST IMPORTANT CONSIDERATIONS ARE: 1)

PROPER WIRE TYPE AND, 2) GOOD, TIGHT CONNECTIONS

FROM THE LOOP TO THE LOOP TERMINATING

CONNECTOR. The termination of the loop wires will be at the

vehicle detector itself, and not at the RS4000 terminal panel. Observe

the wiring diagram supplied by the vehicle detector manufacturer.

The vehicle detector may be mounted inside of the RS4000 operator

cover, provided there is adequate room. The AC power service

delivered to the RS4000 operator may be tapped to provide 115 VAC

service to the vehicle detector.

Two different types of loop installations will usually be encountered

when placing the loops in the drive: 1) If the driveway material is

already in place. saw cuts will be needed in which to place the loop

wire. 2) For loops where the paving material will be installed after

the loop is positioned, it is necessary to place the loops in Schedule

40 PVC pipe to maintain uniform loop spacing with respect to the

surface of the pavement. The loop should be placed 1.5" below the

surface of the pavement and at least 2" above any reinforcing steel.

The lead-in wires need not be in PVC, but must have at least six (6)

twists per running foot.

THE LOOP WIRES MUST BE CONTINUOUS. NO SPLICES OR

CONNECTIONS IN THE LOOP ARE TO BE PERMITTED

BELOW GROUND. THE ONLY CONNECTION WILL BE AT

THE TERMINATION OF THE WIRE AT THE VEHICLE

DETECTOR. Above ground splices may be used providing the wire

is twisted, soldered and moisture sealed. For best long term results,

do not use wire nuts anywhere in the loop system. Connect to the

vehicle detector harness by soldering.

For saw-cut installations, observe the methods recommended in

Figure 7, above. The saw-cut must be to a depth of 1.5", clean and

with no sharp corners. After placing the wires, it is essential that the

wires be held tightly in place by a foam backing prior to pouring the

sealant. THIS IS ESPECIALLY IMPORTANT WHEN FREEZING

IS LIKELY. No voids should exist that will permit the collection of

water that might freeze and push the loop wires out of the slot. The

sealant used should not be hard setting and should be suitable for

pavement material.

THE WIRE USED FOR THE LOOPS MUST BE HEAT AND

WATER RESISTANT, CROSS-LINK POLYETHYLENE

INSULATED. TYPE XLPE IS BEST. RHW IS O.K. DO NOT USE

ANY PVC INSULATED WIRE. (PVC insulation will absorb

moisture that may affect Detector operation.) WIRE SIZE SHOULD

BE #16 GA. STRANDED OR LARGER.

IN

OUT

IN

OUT

Figure 7: Loop Diagrams

106508

B: PREPARING THE SITE