11

INSTALLING THE GATE ARM KIT

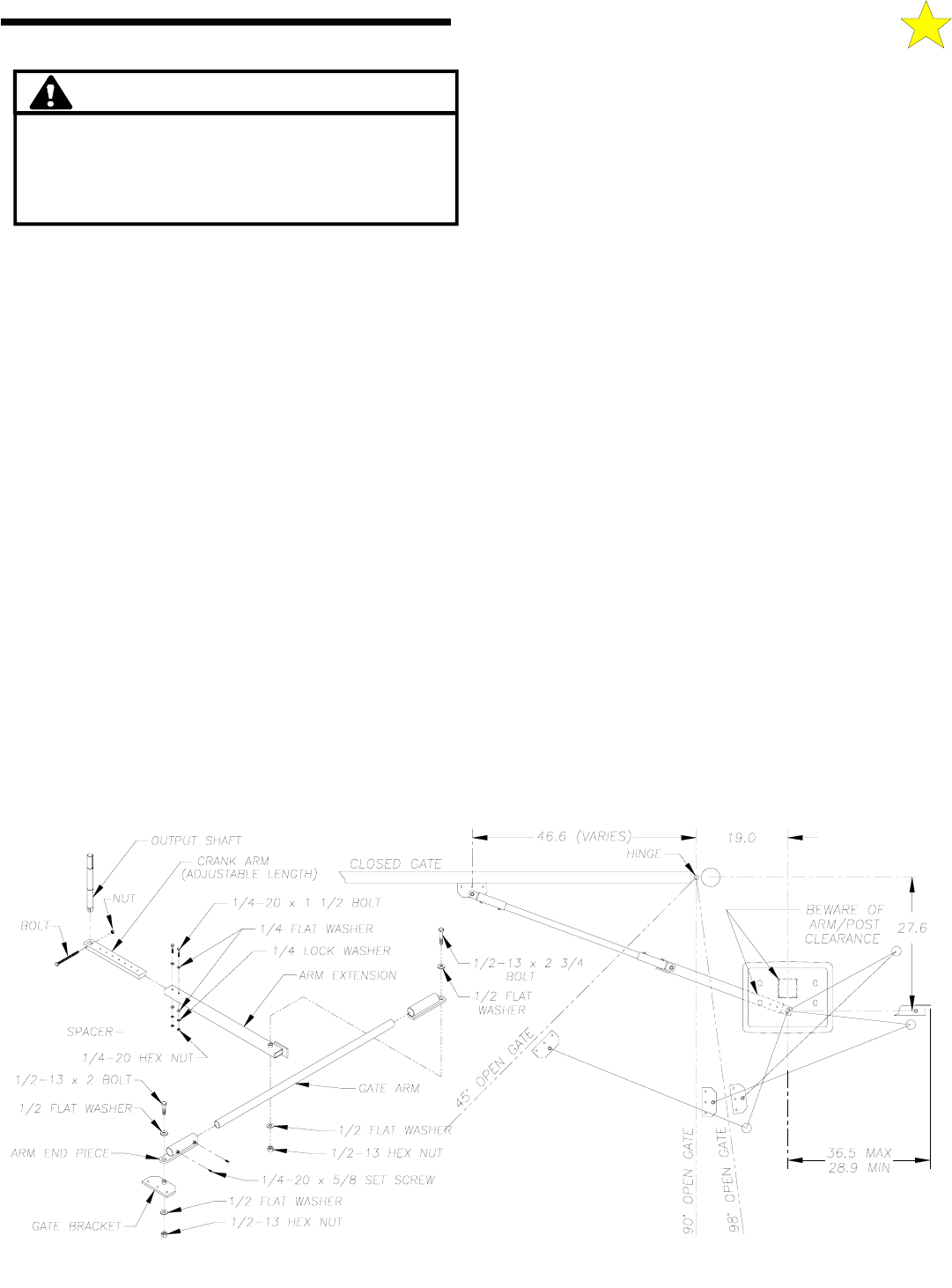

The gate arm kit can be installed on the RS4000 only after the

operator has been properly and securely installed, and the correct

gate/operator geometry relationship has been established and

verified. (See Figures 6 and 10.)

Locate the crank arm in the gate arm kit and install it on the output

shaft of the RS4000 at the underside of the chassis, oriented so the

through hole in the crank arm is aligned with the through hole in the

output shaft. The crank arm is secured to the output shaft with a 5/16-

18 x 2” long bolt and nylon stopping nut.

Get the crank arm extension from the arm kit and slide it on the crank

arm. This assembly can telescope to various arm lengths depending

on which pair of holes is used. Six length settings are possible: 33-

3/8, 31-7/8, 30-3/8, 28-7/8, 27-3/8 and 25-7/8 inches. Choose the

length that is most appropriate for the gate system. Typically, the

longer the gate, the longer the arm should be to provide more stable

gate handling. Secure the extension to the crank arm with the two

1/4-20 x 1-1/2 inch long bolts, flat washers, lock washers, and nuts

provided.

Next, install a gate arm end piece at each end of the pipe as shown in

Figure 10. The length of this arm is also variable depending on where

the end pieces are snugged down with the four 5/16-18 x 5/8 inch

long square head set screws (two, each end piece). The length of the

gate arm pipe may also be cut to length to suit the needs of the gate

system, although this is not recommended, because a longer arm will

promote more stable gate operation.

Install the gate bracket through the eyelet of the arm end piece and

secure it in place with the 1/2-13 x 2” long bolt as shown in

Figurez10, using the two flat washers and Nylok nut provided.

The RS4000 operator was designed with an Adjustable Torque

Output Drive. (“ATD”) (See Figure 9.) For initial installation of the

gate arm, the drive should be adjusted to zero torque, so the crank

arm will swing freely. This is accomplished by loosening (do not

remove) the two reducer-slide clamp bolts on each side of the shaft

support tower. To prevent accidental damage to the limits, etc., the

trigger pin should be removed at this time as shown in Figure 18.

The tension on the flat poly-v adjustable torque drive belt can now be

relieved a small amount at a time until the large pulley installed on

the output shaft will just slip when the crank arm is manually rotated.

The tension is increased or decreased by turning the cap-nutted

tensioning bolts as shown in Figure 9. Note: The capnuts have been

permanently installed on the threaded shank and will not loosen or

un-thread).

Next, manually swing the crank arm to the position shown for a

closed gate in Figure 10. Now install the gate arm pipe assembly on

the end of the crank arm by dropping the end piece eyelet over the

protruding sleeve of the crank arm extension, as shown. Swing the

gate arm assembly around until it is straight in line with the crank

arm, and the “elbow” is up against the closed position stop.

Swing this locked arm assembly around until the gate bracket just

meets the gate as shown in Figure 10. Elevate or lower the arm

assembly until it is level, and then temporarily clamp the gate bracket

to the gate. The “elbow” pivot of the gate arm assembly should be

secured with the 1/2-13 x 2-3/4” long bolt, with flat washers and lock

nut, provided.

Now manually move the gate to the fully opened position, moving

cautiously at first, to ensure there is no interference between gate arm

components or the operator/pedestal. Slight adjustments to the gate

bracket location or arm length may be necessary to ensure smooth

operation. Make several trial runs by manually moving the gate from

closed to opened positions, until a smoothly operating gate system is

assured. When satisfied, weld or bolt the gate bracket to the gate and

remove the clamps.

TO PREVENT DAMAGE TO THE LIMITS, ETC.,

DURING INSTALLATION OF THE GATE ARM,

REMOVE THE LIMIT TRIGGER PIN PRIOR TO

INSTALLING THE GATE ARM

CAUTION!

106511

Figure 10: Arm Positions

C: INSTALLING THE OPERATOR