17

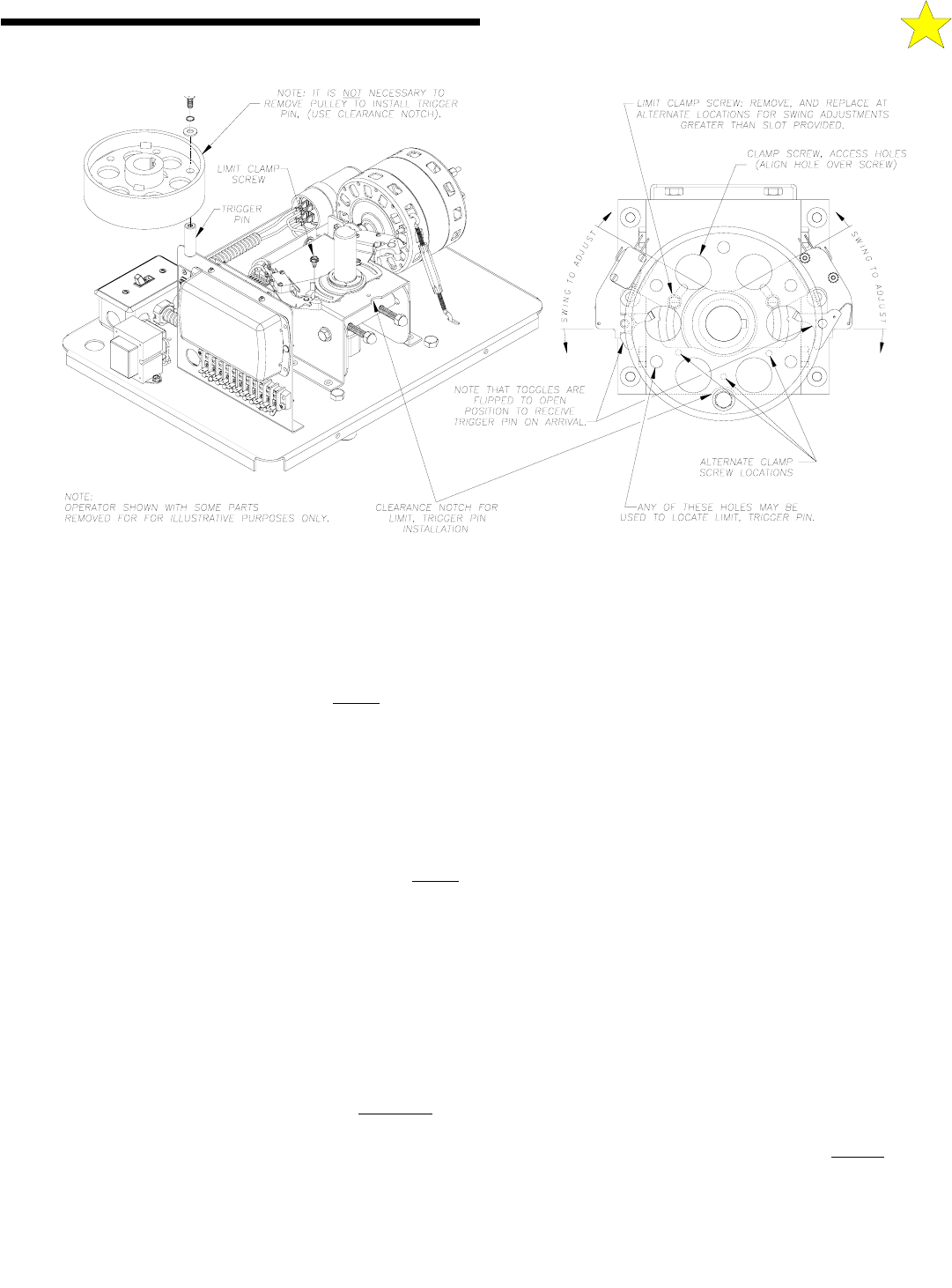

mounting hole is positioned directly above the clearance notch

provided in the shaft support tower (see Figure 18). This notch

provides the appropriate clearance to install the limit trigger pin with

the bolt and washers provided. Install the trigger pin firmly in place.

Flip the toggle open so it is positioned to receive the trigger pin.

Swing the gate to a position that is just a few inches short of the fully

closed position. Now swing the “close” limit bracket

around the

output shaft toward the trigger pin until the toggle just trips to

“close” the micro switch.

The limit brackets are provided with a slot so that they can slide

freely about the limit clamp screw. It may be necessary to relocate

this clamp screw to bring this slot within the range of the trigger pin.

Alternate clamp screw locations have been provided for this purpose.

Flip the “open” limit toggle toward the trigger pin so that it is ready

to receive. Manually swing the gate to a position that is just short of

the fully “open” position. Now swing the “open” limit bracket

around the output shaft toward the trigger pin until the toggle just

trips to “close” the micro switch.

Lock the positions of the limit brackets by gently snugging the limit

clamp screws in place.

NOTE: These are the rough settings for the “open” and “close”

limits. Final adjustment will be made after the Adjustable

Torque Drive system has been set.

SETTING ADJUSTABLE TORQUE DRIVE

The RS4000 operator incorporates an Adjustable Torque Drive to

limit the amount of force that the gate arm can exert. This provides

the additional flexibility to fine tune the output of the gate system

.

BEFORE BEGINNING THIS PROCESS, BE SURE THE MAIN

POWER SWITCH TO THE OPERATOR IS

OFF.

Output torque can be increased by turning the belt tensioning bolts in

a clockwise direction. To decrease torque, reduce the belt tension by

turning the tensioning bolts in a counter-clockwise direction. This

allows a controlled slipping action to occur between the flat Poly-V

belt and the large output pulley, similar to that of a clutch

mechanism.

Before turning the tensioning bolts, it is necessary to loosen the four

(4) reducer slide clamp bolts (two each side of the shaft support

tower), and the motor mount clamp nut (see Figure 9). Loosening the

motor mount clamp nut allows the motor/pulley to pivot. Gravity will

tension the V-Belt as the reducer slide moves in and out of the shaft

support tower.

BE SURE POWER IS STILL OFF!

Tension the Poly-V belt by small increments by turning the

tensioning bolts as a balanced pair. After tensioning the Poly-V belt,

test the grip between the belt and drive pulley by applying manual

pressure against the gate and estimating the resistance by the operator

before slipping occurs.

When the desired resistance is achieved, tighten the four reducer

slide clamp bolts. Evaluate the motor drive belt tension by applying a

moderate downward pressure on the belt midway between the two

pulleys. If an excessive amount of deflection occurs, loosen the

clamp nut slightly and apply a slight downward pressure to the

motor. The motor drive belt can be further tensioned by turning

the body nut of the turnbuckle. Turn clockwise to increase belt

tension. Do not over tension. This turnbuckle will also help to

maintain motor belt tension and facilitate easy re-adjustment

should the belt stretch with age. Re-tighten the motor clamp nut.

Additional adjustments may be necessary after the RS4000 operator

has been powered up and is fully operable.

Now that the Adjustable Torque Drive has been set, limit settings

obtained in the previous section must be fine tuned. Move the limit

brackets a degree at time while cycling the operator. Note the gate’s

actual stopping position. Continue to adjust the limit brackets

by very

small increments while cycling the operator until the exact stopping

position desired is reached. Lock the limit brackets in place by

snugging the limit clamp screws. Test and adjust the Torque Drive

setting on a regular basis (at least once per month).

D: STARTING THE

106512

Figure 18: Limit Adjustments