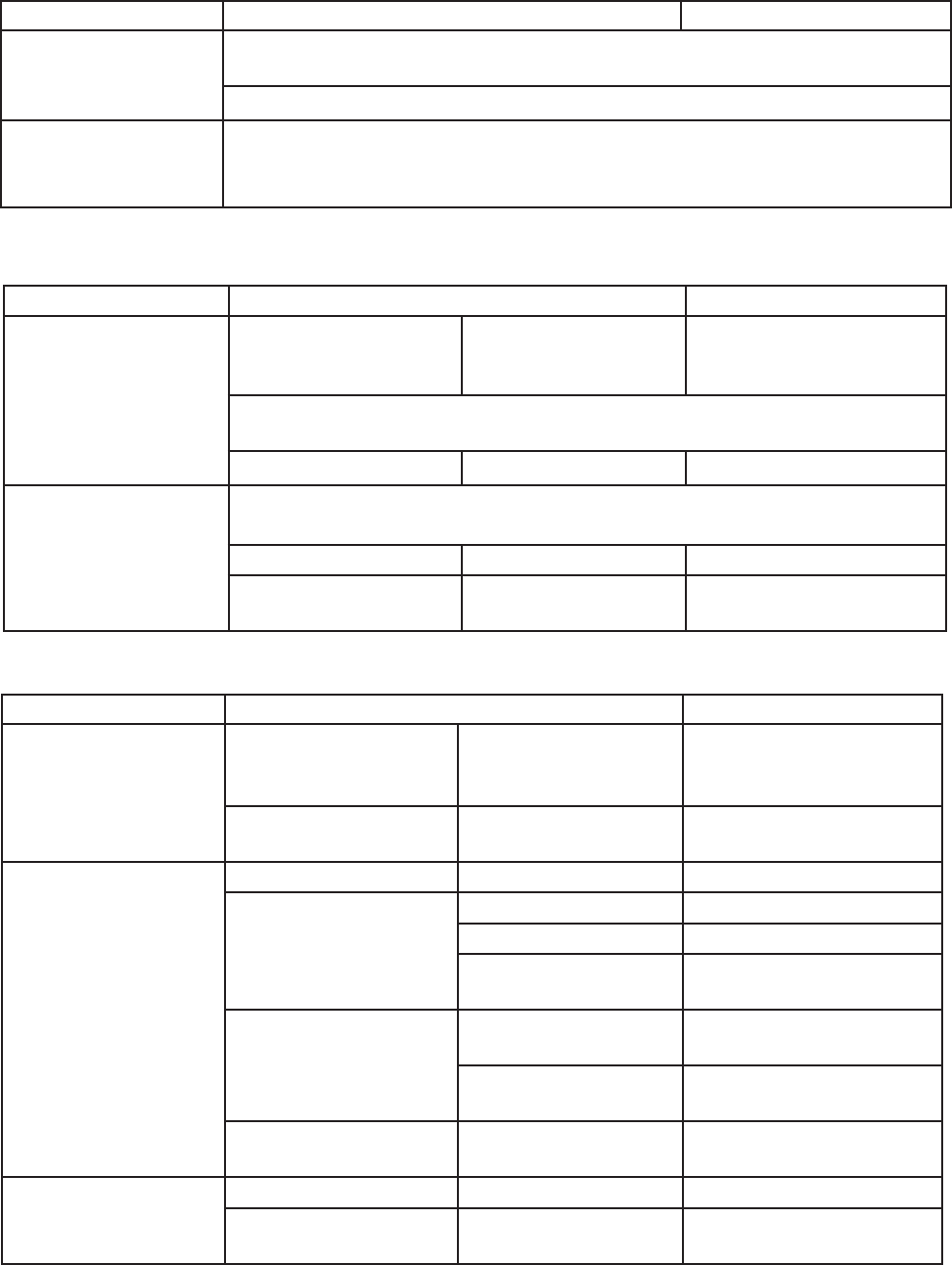

40

Problem Possible Cause Remedy

[1]Icemaker will not stop

when bin is lled with

ice.

a)Bin Control 1. Defective. 1. Replace.

b)Control Board 1. Defective. 1.

See "II.C.4. Control Board

Check Procedure".

[]

Abnormal noise. a)Pump Motor 1. Bearings worn out. 1.Replace.

b)Fan Motor 1. Bearings worn out. 1. Replace.

. Fan blade deformed. . Replace fan blade.

3. Fan blade does not

move freely.

3. Replace.

c) Compressor 1. Bearings worn out or

cylinder valve broken.

1. Replace.

. Mounting pad out of

position.

. Reinstall.

d)Refrigerant Lines 1. Rub or touch other

lines or surfaces.

1. Reposition.

[3]Ice in storage bin

often melts.

a)Bin Drain 1. Plugged. 1.Clean.

b)Icemaker and Bin 1. Drains not run

separately.

1. Separate the drain lines.

4. Abnormal Ice

Problem Possible Cause Remedy

[1] Small cubes. a)Ice Cube Guide or Ice

Separator

1. Out of position.

Circulated water falls

into bin.

1. Place in position.

b)See chart 1.[5] and check water supply line, water valves, water system, pump

motor, and control board.

c) Drain Water Valve 1. Leaking. 1. Check and replace.

[]

Cloudy or irregular

cubes.

a)See chart .[1] and .[3], and check oat switch, water valves, control board,

spray tubes, water system, refrigerant charge, and expansion valve.

b)Spray Guide 1. Dirty. 1. Clean.

c) Water Quality 1. High hardness or

contains impurities.

1. Install a water softener or

lter.

3. Low Ice Production

Problem Possible Cause Remedy

[1]Freeze cycle time is

long.

a)See chart 1.[3]. Also check dirty condenser coil, ambient temperature and

refrigerant charge.

b)See chart .[1] and check oat switch, water valves and control board.

[]

Harvest cycle time is

long.

a)See chart .[] and check evaporator, water supply line, harvest water valve,

ambient and/or water temperature, liquid line valve, thermistor, and control

board.

5. Other