45

Desired Idle – The engine idle speed will be controlled by the ECU and can be changed at different temperatures. If the

engine is cold, the idle speed will need to be higher than if the engine is warm for best idle stability. These values are very

specific to each application. Stock engines can idle as low as 600 RPM and some race engines need to idle over 1300 RPM.

Normally, the cold idle should be about 200-300 rpm higher than the hot idle for most engines.

IAC Parked position – This is the position of the idle air motor when the engine is starting. It is a fixed value depending on

engine temperature. This is an important value to help proper startup of the engine. If it is too far closed during cranking the

engine will not have enough air to start, and may struggle after it fires. If it is too far open it may have too much air. If the

engine starts and revs at a high rpm, then falls to its idle speed, the parked position may be too high. Mild small block V8

engines usually have values between 100 and 40 from cold to hot engine temperature. High performance big block engines

may need values from 200 to 60 from cold to hot temperatures.

Minimum IAC Position – This table allows the user to cause the IAC to “follow” the throttle position. As the throttle is

opened, you want the IAC to open also. This is to keep the engine from stalling when the throttle is instantly released. The

IAC will not close lower than the throttle follower position, so you will want to set the throttle follower at zero for the idle TPS

position and quickly ramp the IAC open after that.

5. Closed Loop Operation – One of the major benefits of EFI is the ability to run closed loop. To explain closed loop

operation simply, an oxygen sensor provides feedback to the ECU, which allows the ECU to automatically adjust the

amount of fuel injected to maintain a 14.7:1 air/fuel ratio. A 14.7:1 air/fuel ratio has several benefits:

A. Provides good fuel economy

B. This air/fuel ratio is required for typical catalytic converters to operate efficiently

C. Provides good part throttle performance

D. Creates efficient combustion which extends the life of the engine and allows for the spark plugs to burn clean

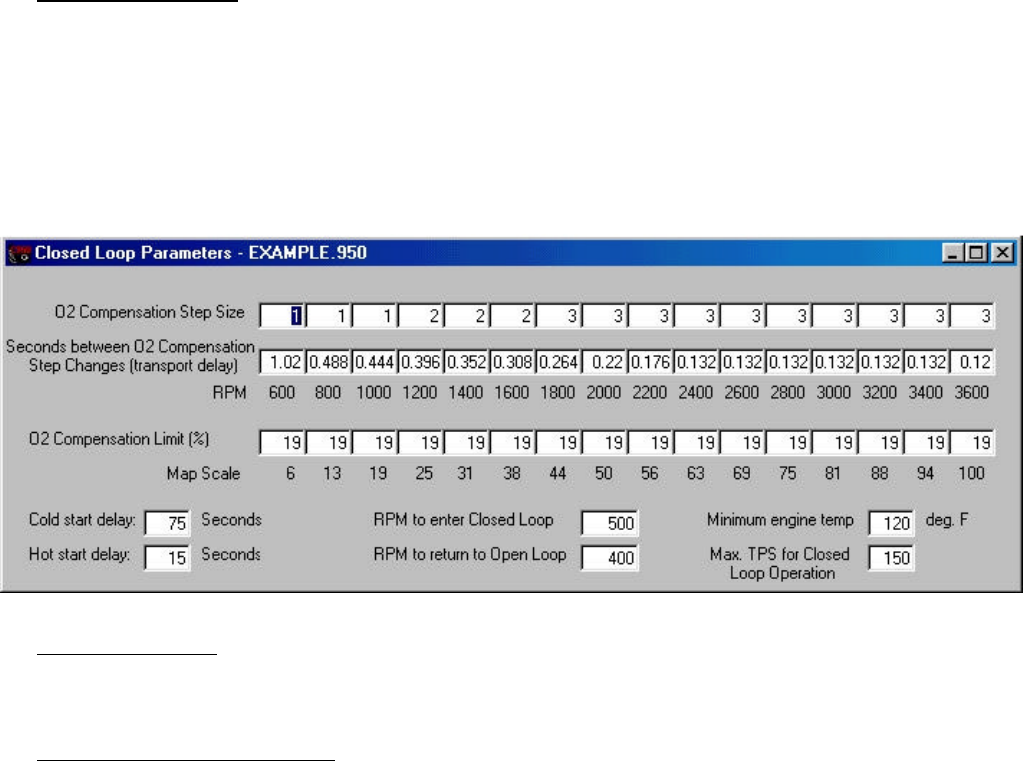

There are several parameters that can be adjusted that relate to closed loop operation on the Commander 950. They are

described below.

Figure 29 Closed Loop Parameters

Minimum engine temp – The minimum engine coolant temperature (F) at which an engine will go into a closed loop mode.

When any engine is cold, it needs more fuel to run smoothly. It needs to get the pistons and combustion chambers up to

temperature before closed loop operation can begin. Most engines can smoothly begin closed loop operation at about

110-120° F. Engines with bigger camshafts may need to delay this until about 140-150° F.

Max. TPS for Closed Loop Operation – The TPS position that an engine changes from closed to open loop. An engine

needs to operate at an air/fuel ratio richer than 14.7:1 for best and safest power. This is typically between 12.5 and 13.2

for naturally aspirated engines. For this reason, an engine needs to run open loop when engine load increases and at

WOT. The TPS value you input depends on several factors. Keep in mind the following:

1. The design of the throttle body has a big effect. Two opposite examples would be an engine with a 4 bbl progressive

throttle body and one with an 80 mm single blade throttle body. If each one were open half way, the 80 mm would

flow more air on a percentage basis due to the design of the throttle body. The 4 bbl with its progressive linkage

would be flowing less air due to its design. The 80 mm would need to go open loop sooner as it will allow more air to

enter (and consequently the engine would make more power sooner) than the progressive 4 bbl.

2. This value is also adjusted based on the feel of the vehicle. If it feels better to increase or decrease this value do it.