12

O

2

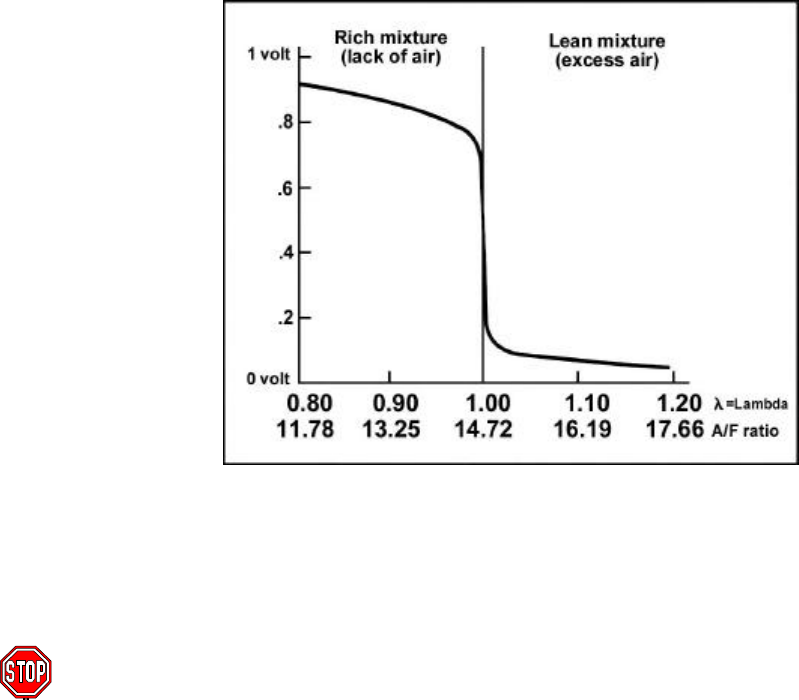

Sensor Voltage

1.21 Open Loop

Open loop defines the engine operation where the fueling level is calculated by the ECU with only the input signals from the

throttle position sensor (TPS), from the coolant and/or air charge temperature, and from the manifold absolute pressure

(MAP).

For additional information, see Appendix 7 (Description of Fuel Injection Systems)

2.0 How Does Fuel Injection Work?

A fuel injection system is made up of many specialized components that are designed to work together to properly meter fuel

and air. A properly tuned EFI system will allow for the optimum air/fuel ratio during all operating conditions. The Commander

950 is easily adjustable to realize all of the benefits EFI will deliver.

The main components that make up a fuel injection system are a combination of mechanical and electrical devices. These

typically include:

Ø EFI Intake Manifold

Ø Throttle Body (also called Air Valve)

Ø Fuel Injectors

Ø High-Pressure Fuel Pump

Ø Fuel Pressure Regulator

Ø Engine Coolant Temperature Sensor (ECT)

Ø Manifold Air Temperature Sensor

Ø Manifold Air Pressure Sensor (MAP Sensor)

Ø Oxygen Sensor (O

2

Sensor)

Ø Throttle Position Sensor (TPS)

Ø Idle Air Control Motor (IAC)

Ø RPM Signal Device (distributor or crank trigger)

Ø Computer (Electronic Control Unit (ECU)

NOTE: If you are not familiar with ALL of these terms, please refer to the glossary in Chapter 1.

Let’s take a closer look at what makes fuel injection work.

The fuel injection cycle begins by air entering the engine through the throttle body. The ECU needs to then calculate how

much fuel to add for the amount of air that is entering the engine. Although there are several methods to do this, the

Commander 950 uses inputs from the MAP Sensor and engine speed to calculate an initial amount of fuel to inject. The MAP

sensor indicates the load on the engine by sensing manifold vacuum.