into its cylinder to accommodate them. This

will cause the fluid level to rise in the reservoir.

Anticipate this by syphoning some out

beforehand, but take care not to let it drip

onto the paintwork - it acts as an effective

paint stripperl

8 Refit the anti-rattle springs, the pads

(friction lining-to-disc), the cylinder body, the

locking blocks and their retaining clips

(photos).

9 Refit the roadwheel and apply the footbrake

hard, several times, to bring the pads into

contact with the brake disc.

10 Renew the pads on the opposite brake.

The pads should always be renewed in axle

sets.

11 Top up the fluid reservoir.

4 Rear brake shoes -

inspection and renewal

2

1 Jack up the rear of the car and remove the

roadwheels.

2 Fully release the handbrake.

3 Unscrew and remove the drum securing

bolts. One of these is a long locating spigot

for the roadwheel.

4 Pull off the drum. lf it is tight, clean off the

rust at its joint with the hub flange, and apply

a little penetrating fluid. Two bolts may be

screwed into the drum securing bolt holes if

necessary and the drum thus eased off the

hub. The securing bolt holes are tapped for

this purpose.

5 Brush away all the dust and dirt from the

shoes and operating mechanism, taking care

not to inhale it.

6 The friction linings fitted as original

equipment are of the bonded type and the

rivet heads normally used as a guide to wear

are not, of course, fitted. However, if the

thickness of the friction linings is down to

1.5 mm (0.06 in) or less, the shoes must be

renewed. Always purchase new or factory

relined brake shoes.

7 Before removing the brake shoes, note the

way in which the shoes are positioned, with

respect to leading and trailing ends (the end

of the shoe not covered by lining material).

Note also into which holes in the shoe web

the return springs are connected. Sketch the

shoes or mark the holes on the new shoes

with quick drying paint if you are doubtful

about remembering (photo).

8 Undo the steady springs by depressing and

rotating their caps a quarter turn to disengage

the slot from the pin. On later models a

U-shaped steady spring is used. Depress and

slide it out.

9 Rotate the hub until the cut-outs in its rear

flange face are in alignment with the shoe

self-adjusters.

10 Pivot the trailing shoe on the self-adjuster

post and disengage the ends of the shoe from

the slot in the wheel cylinder tappet and from

the lower anchor block.

11 Work the shoe up the self-adjuster pivot

post until the self-adjuster boss enters the

cut-out in the hub flange. The shoe can now

be withdrawn (photo).

12 Once off the self-adjuster post, the

pull-off spring tension is eased, as the shoe

can move towards the other, so the springs

can be unhooked.

13 Remove the leading shoe in a similar way.

14 The new shoes will already be fitted with

new self-adjusters.

15 Fit the new shoes to their self-adjuster

posts, making sure that the handbrake shoe

lever is correctly located. Engage the ends of

the shoes.

16 Using a wooden or plastic-faced mallet,

tap the shoes inwards against the friction of

their self-adjuster coil springs. This will have

the effect of reducing the overall diameter of

the shoes to facilitate fitting of the shoe return

springs and to allow the brake drum to slide

over them.

17 Using pliers, reconnect the upper (longer)

and lower shoe return springs.

18 Hold the steady pins in position from the

rear of the backplate. Fit the small coil springs

and the retaining cap, again using pliers to

grip the cap and to depress and turn it to

engage the pin. On later models fit the

U-shaped springs.

19 Before refitting the drum, clean it out and

examine it for grooves or scoring (refer to

Section 8).

20 Fit the drum and the roadwheel.

21 Apply the brakes two or three times to

position the shoes close to the drum.

22 Renew the shoes on the opposite brake in

a similar way.

23 The handbrake should be automatically

adjusted by the action of the shoe adjuster. If

the handbrake control lever has excessive

travel, refer to Section 16 for separate

adjusting instructions.

5 Caliper - removal,

overhaul and refitting

4

Note: Purchase a repair kit in advance of

overhaul.

1 Jack up the front roadwheel and remove it.

2 Brush away all dirt from the caliper

Braking system 8•3

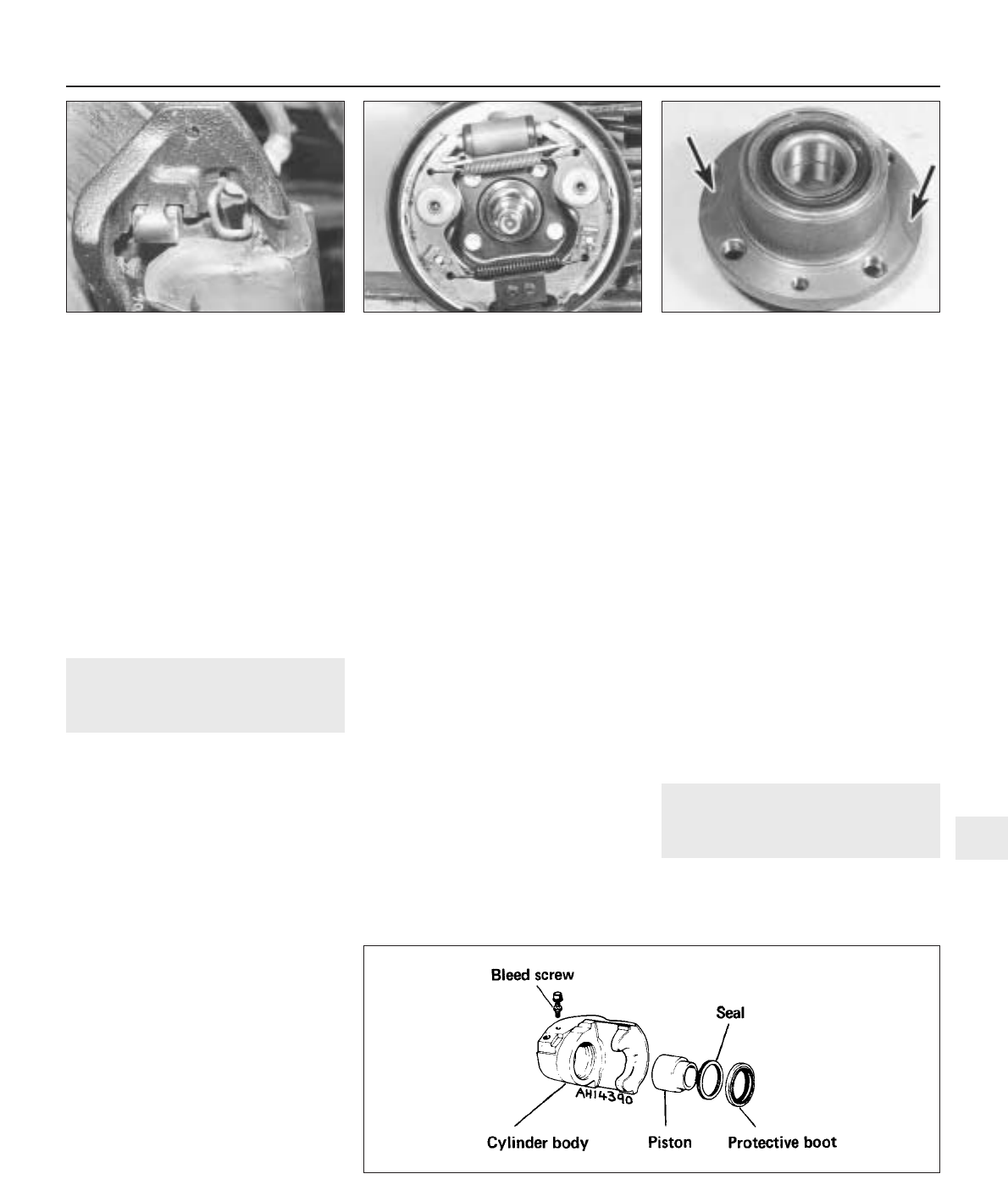

4.11 Rear hub showing cut-outs on rear

face for shoe self-adjuster bosses

4.7 Rear brake assembly3.8B Cylinder body located on caliper

bracket

Fig. 8.2 Exploded view of caliper (Sec 5)

8