VALVES AND VALVE SPRINGS

5-17

EAS24280

REMOVING THE VALVES

The following procedure applies to all of the

valves and related components.

TIP

Before removing the internal parts of the cylin-

der head (e.g., valves, valve springs, valve

seats), make sure the valves properly seal.

1. Check:

• Valve sealing

Leakage at the valve seat → Check the

valve face, valve seat, and valve seat

width.

Refer to “CHECKING THE VALVE

SEATS” on page 5-19.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Pour a clean solvent “a” into the intake and

exhaust ports.

b. Check that the valves properly seal.

TIP

There should be no leakage at the valve seat

“1”.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

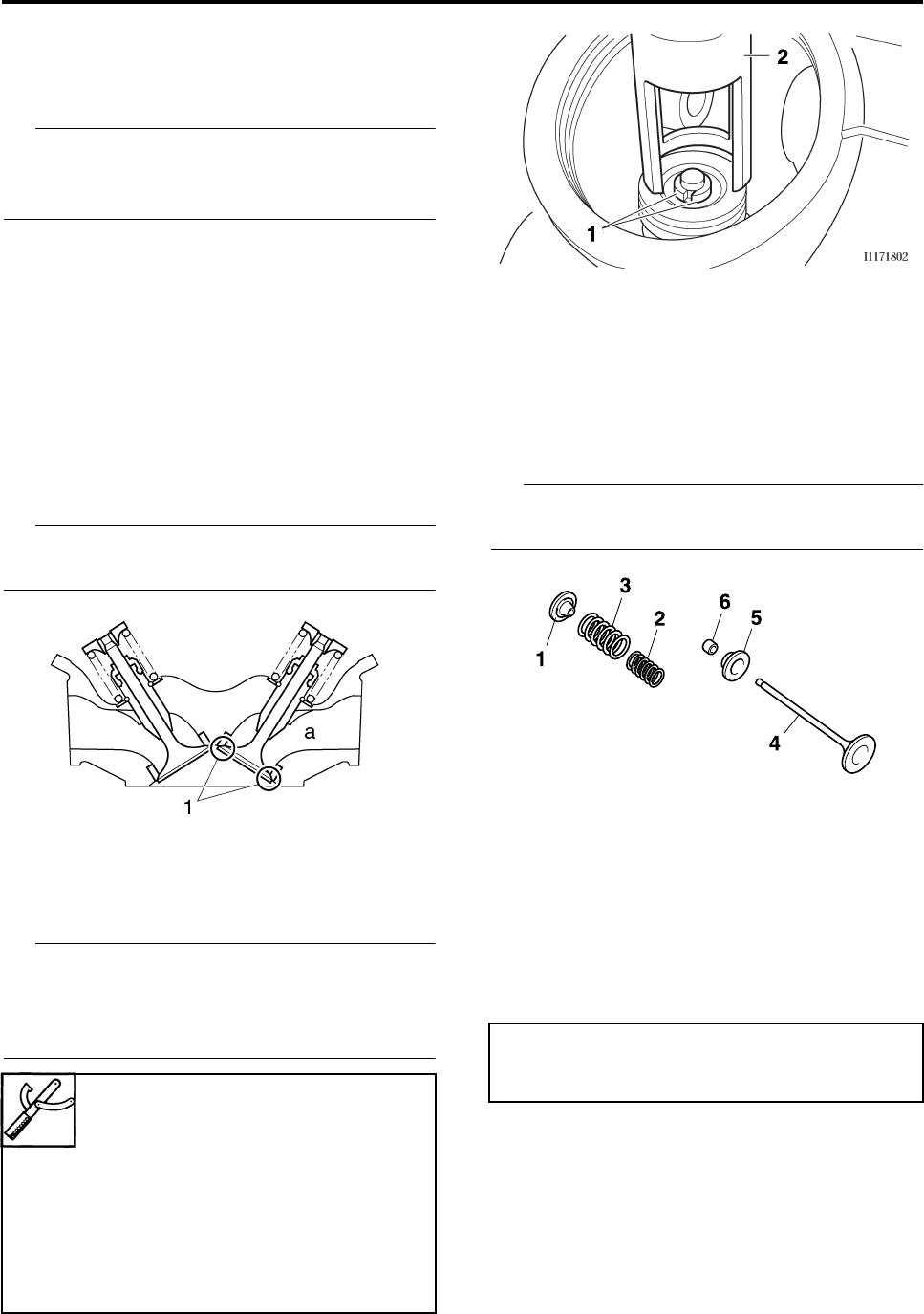

2. Remove:

• Valve cotters “1”

TIP

Remove the valve cotters by compressing the

valve spring with the valve spring compressor

and the valve spring compressor attachment

“2”.

3. Remove:

• Upper spring seat “1”

• Inner valve spring “2”

• Outer valve spring “3”

•Valve “4”

• Lower spring seat “5”

• Valve stem seal “6”

TIP

Identify the position of each part very carefully

so that it can be reinstalled in its original place.

EAS24290

CHECKING THE VALVES AND VALVE

GUIDES

The following procedure applies to all of the

valves and valve guides.

1. Measure:

• Valve-stem-to-valve-guide clearance

Out of specification → Replace the valve

guide.

Valve spring compressor

90890-04019

YM-04019

Valve spring compressor

attachment

90890-01243

Valve spring compressor

adapter (26 mm)

YM-01253-1

• Valve-stem-to-valve-guide clearance =

Valve guide inside diameter “a” -

Valve stem diameter “b”