07 Wheels and tyres

166

Emergency puncture repair

07

Sealing punctured tyres

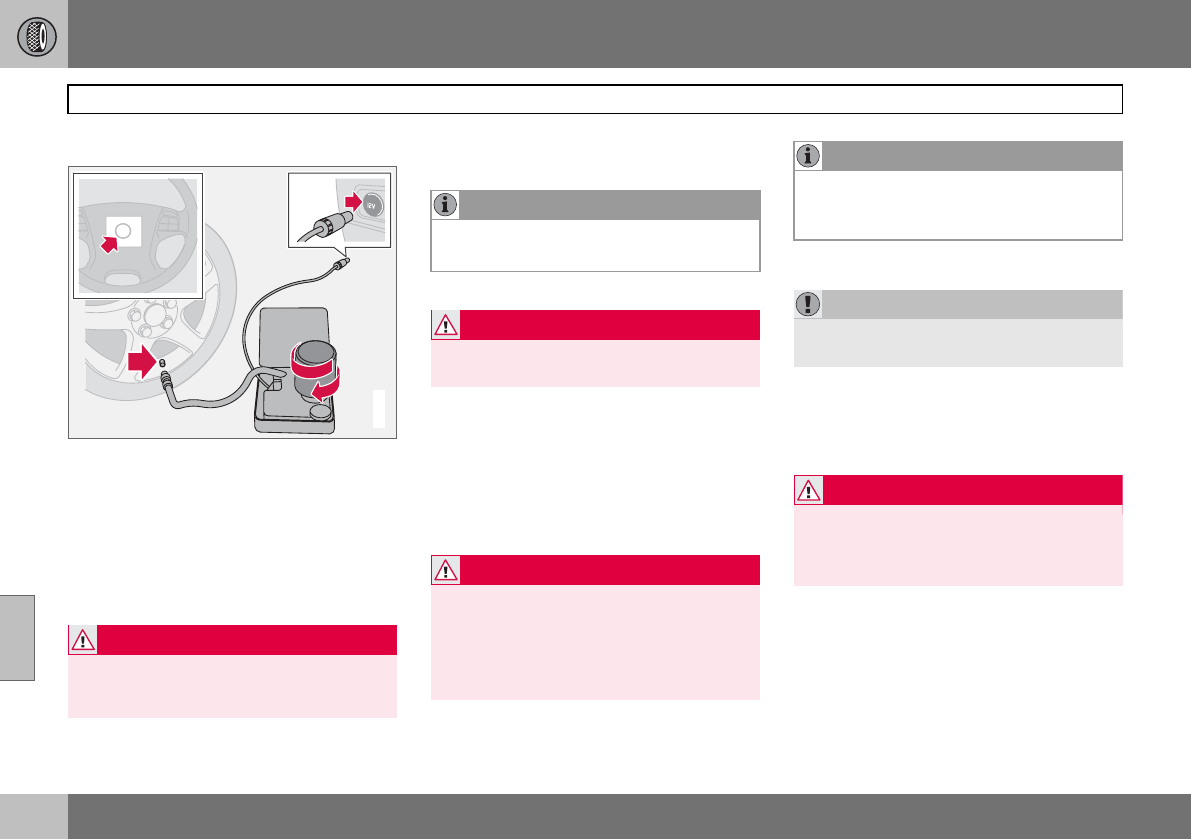

For information on the function of the parts, see

the illustration on page 165.

– Open the lid of the emergency puncture

repair kit.

– Detach the decal for maximum permitted

speed and affix it to the steering wheel.

– Check that the switch is in position 0 and

locate the cable and the air hose.

– Unscrew the orange cap and unscrew the

bottle’s stopper.

– Screw the bottle into its holder.

– Unscrew the wheel’s dust cap and screw

in the air hose valve connection to the

bottom of the thread on the tyre’s air

valve.

– Plug the cable into the 12 V socket and

start the car.

– Flick the switch to position I.

– Inflate the tyre for 7 minutes.

– Switch off the compressor to check the

pressure on the pressure gauge. Minimum

pressure is 1.8 bar and maximum is

3.5 bar.

– Switch off the compressor and unplug the

cable from the 12 V socket.

– Detach the hose from the tyre’s air valve

and fit the valve’s dust cap.

– As soon as possible, drive approximately

3 km at a maximum speed of 80 km/h so

that the sealing fluid can seal the tyre.

WARNING

The sealing fluid can irritate the skin. In the

case of contact with skin, wash away the

fluid with soap and water.

80

50

G019723

NOTE

Do not break the bottle seal. The seal is bro-

ken when the bottle is screwed in.

WARNING

Do not unscrew the bottle, it is equipped

with a reverse catch to prevent leakage.

WARNING

Never stand next to the tyre when the com-

pressor is running. If cracks or unevenness

arise then the compressor must be

switched off immediately. The journey

should not be continued. Contact an

authorised tyre centre.

NOTE

When the compressor starts, the pressure

can increase up to 6 bar but the pressure

drops after approximately 30 seconds.

IMPORTANT

Risk of overheating. The compressor must

not run for more than 10 minutes.

WARNING

If the pressure is below 1.8 bar then the

hole in the tyre is too big. The journey

should not be continued. Contact an

authorised tyre centre.