10

6

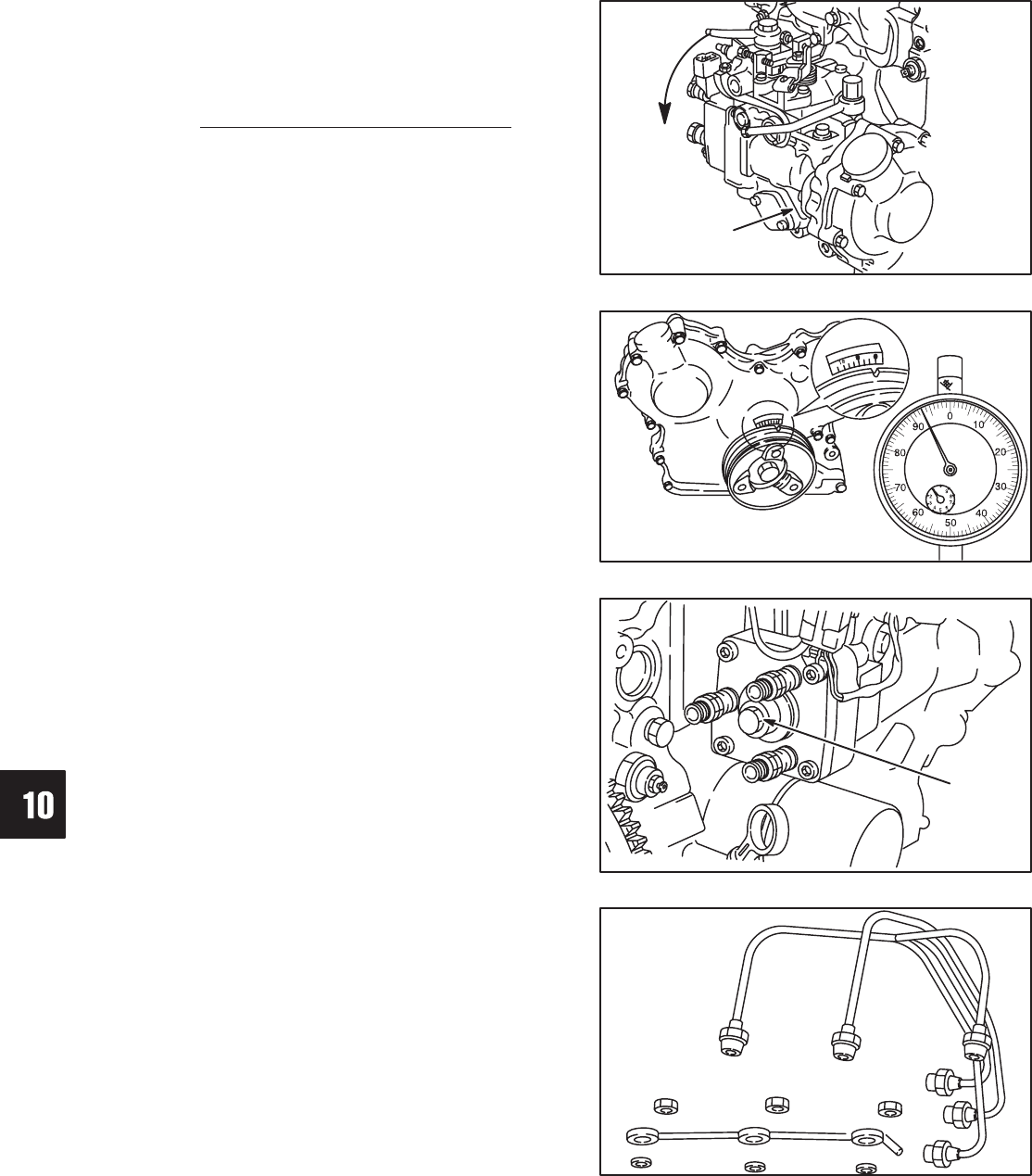

INJECTOR PUMP

3. While observing dial indicator, slowly rotate injec-

tor pump away from cylinder head until indicator

shows correct specification. Hold injector pump in

this position and tighten outside pump mounting

nut, Fig. 9.

NOTE: Do not rotate pump past specification. If

pump is rotated past specification, rotate

pump back toward cylinder head and

repeat procedure.

Fig. 9 – Adjusting Timing

OUTSIDE MOUNTING

NUT

4. To verify that timing is correct, rotate crankshaft

counter-clockwise until dial indicator reads ‘‘0.”

Then rotate crankshaft clockwise until timing

mark on pulley aligns with reference point on gear

case cover (TDC). Indicator should be within

specification, Fig. 10.

5. Torque injector pump mounting nuts and pump

support bracket screw to 19.0 Nm (170 in. lbs.).

Fig. 10 – Verify Timing

METRIC INDICATOR

SHOWN

6. Remove timing gage and install distributor screw

with new washer, Fig. 11.

a. Torque screw to 17.0 Nm (150 in. lbs.).

7. Install fuel delivery lines.

a. Torque to 25.0 Nm (220 in. lbs.).

Fig. 11 – Installing Distributor Screw

DISTRIBUTOR

SCREW

INJECTORS

Remove Injectors

NOTE: Use care to prevent any dirt from entering

injector holes or delivery valve ports when

fuel delivery lines are removed.

1. Remove fuel delivery lines, Fig. 12.

2. Disconnect fuel return line hose.

3. Remove nuts and fuel return line.

a. Discard fuel return line gaskets.

Fig. 12 – Removing Fuel Lines