FUEL SYSTEM AND GOVERNOR

53

8. Remove the pin that the float hinges on to remove

the float.

NOTE: The float is not adjustable. Spring tension against

the float valve begins to build from the horizontal

position, putting progressively more pressure

between the tip of the valve and the seat.

See Figure 4.28.

NOTE: Because the float valve is crucial to the functioning

of the carburetor, and the viton tip of the valve is

subject to wear, technicians should replace the

valve and spring any time the carburetor is disas

-

sembled for cleaning.

• A square cross-section gasket seals the bowl to

the body of the carburetor.

9. Remove the main jet using a narrow-shank straight

blade screwdriver.

See Figure 4.29.

NOTE: Fuel enters the central column through a port

about 1/2” (1cm) from the bottom, to help prevent

the ingress of any residue in the bottom of the

bowl.

NOTE: The orifice in the main jet meters fuel into the cen-

tral column.

NOTE: Air from the main jet emulsion port enters the cen-

tral column near the top, then gets bubbled

through the emulsion tube into the metered fuel

flow to promote atomization.

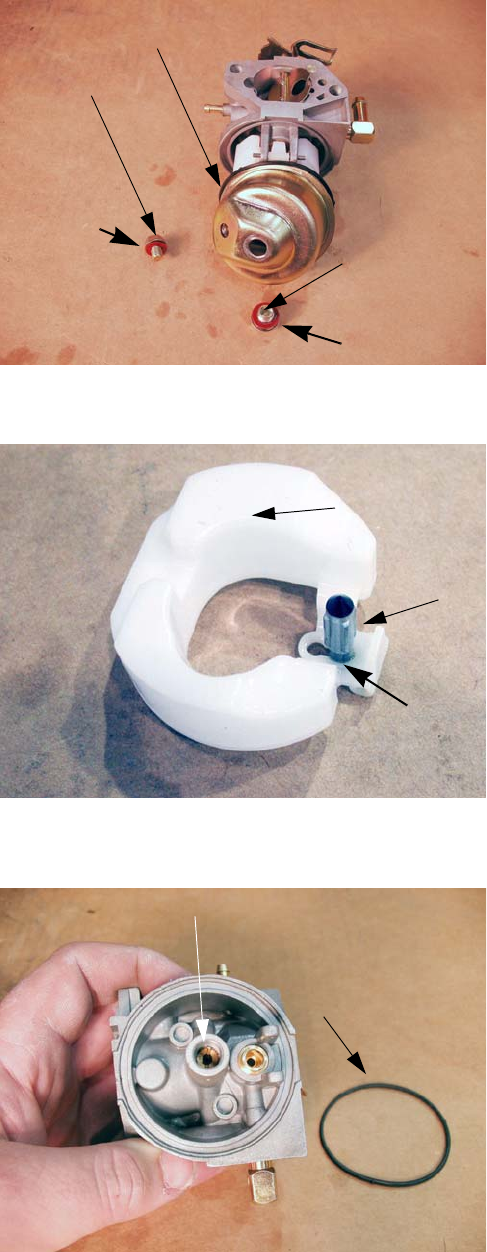

Figure 4.27

Float bowl

Drain bolt

Flat fiber

gasket

Bowl bolt

with recess in

head for O-ring

Gasket seal

Figure 4.28

Float

Compression

spring

Float valve

Figure 4.29

Main jet

Bowl gasket

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com