Crankshaft, piston and connecting rod

109

Piston Inspection

1. Clean the piston and remove all carbon from the rings

and ring groves.

2. Clean the cylinder bore and remove all carbon.

3. Insert one ring into the cylinder. Push it down about

one inch from the top.

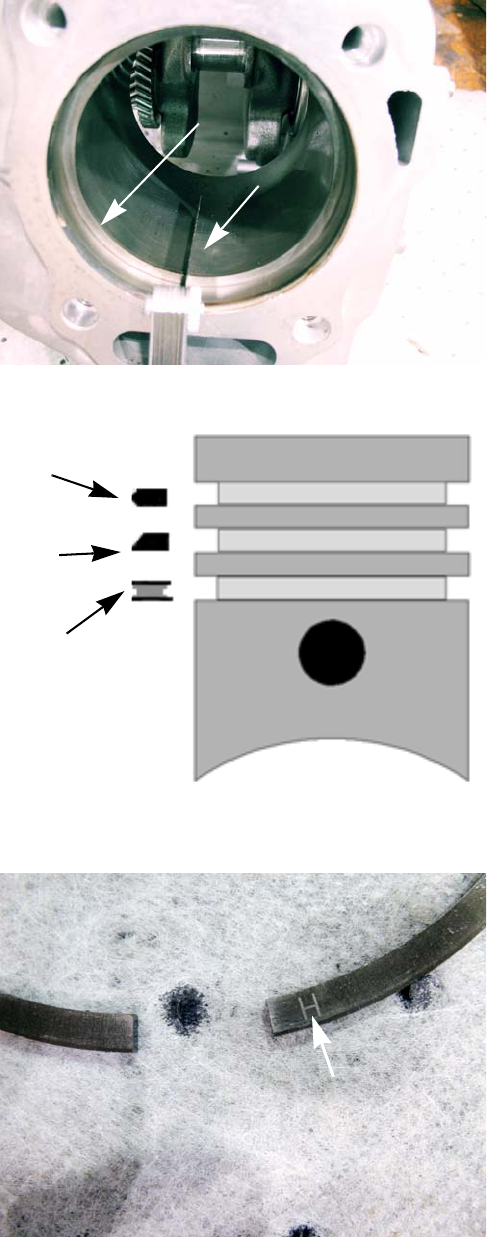

See Figure 10.8.

4. Measure the end gap with a feeler gauge and com-

pare to the chart at the end of this chapter.

See Figure 10.8.

5. Repeat steps 3 and 4 on the other rings.

NOTE: Piston rings are not available as service parts. If

any of the end gaps are out of spec, the engine

must be short blocked.

6. Install rings back onto the piston.

NOTE: The compression rings on the MTD engine have

different profiles. It is important that the proper pro

-

filed ring is on the right grove. See Figure 10.9.

NOTE: To help identify the top surface of the middle piston

ring, it has an “H” etched on it.

See Figure 10.10.

Figure 10.8

Feeler gauge

Piston ring

Figure 10.9

Top piston ring

Middle piston

3-piece oil ring

ring

Figure 10.10

“H” etched on the top surface

of the middle piston ring

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com