PM-19

PERIODIC MAINTENANCE SERVICES

Cooling System

11.Cooling System

A: INSPECTION

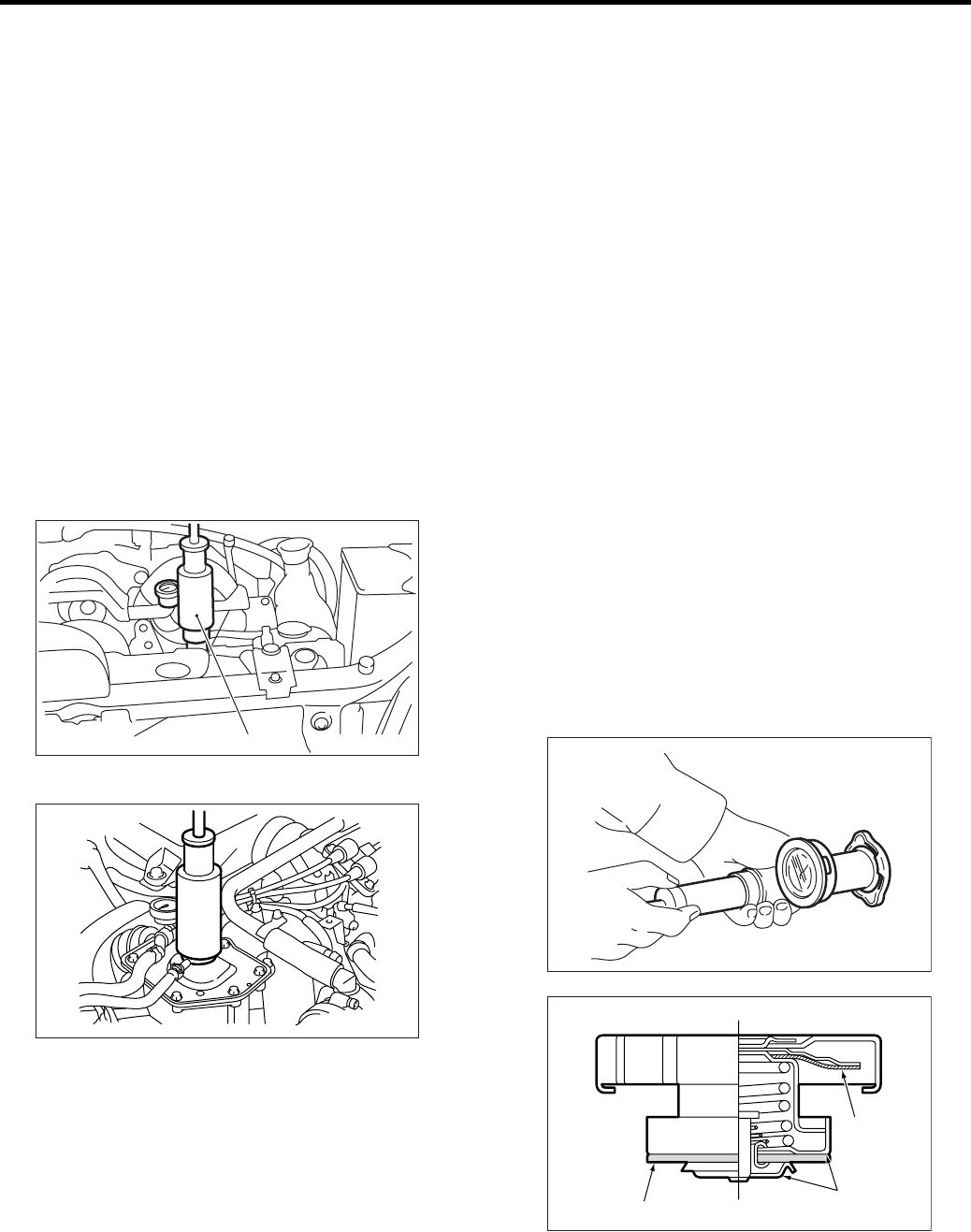

1) Check the radiator for leakage, filling it with cool-

ant and attach the radiator cap tester (A) to filler

neck. Then apply a pressure.

Check the following points:

Non-turbo model

157 kPa (1.6 kg/cm

2

, 23 psi)

Turbo model

122 kPa (1.2 kg/cm

2

, 18 psi)

• Each portion of radiator for leakage

• Hose joints and other connections for leakage

NOTE:

• For turbo model, be sure to install the tester to fill-

er tank side.

• When attaching or detaching tester and when

operating tester, use special care not to deform ra-

diator filler neck.

NON-TURBO MODEL

TURBO MODEL

• When performing this check, be sure to keep the

engine stationary and fill the radiator with coolant.

• Wipe off check points before applying pressure.

• Use care not to spill coolant when detaching the

tester from radiator.

• Do not remove the radiator side cap. (Turbo

model)

2) Check the radiator cap valve open pressure us-

ing radiator cap tester.

NOTE:

Rust or dirt on the cap may prevent the valve from

functioning normally: be sure to clean the cap be-

fore testing.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for 5 to 6

seconds. The radiator cap is normal if a pressure

above the service limit value has been maintained

for this period.

Radiator cap valve open pressure

Non-turbo model

Standard value:

93 — 123 kPa (0.95 — 1.25 kg/cm

2

, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm

2

, 12 psi)

Turbo model

Filler tank side:

Standard value:

93 — 123 kPa (0.95 — 1.25 kg/cm

2

, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm

2

, 12 psi)

Radiator side:

Standard value:

122 — 152 kPa (1.24 — 1.55 kg/cm

2

, 18 —

22 psi)

Service limit:

112 kPa (1.14 kg/cm

2

, 16 psi)

PM-00128

(A)

PM-00150

(A)

(A) Deformation

(B) Deformation, damage, rust

PM-00023

PM-00089

(B)

(A)

(A)