PM-44

PERIODIC MAINTENANCE SERVICES

Steering System (Power Steering)

(2) Retighten the adjusting screw to 7.4 N·m

(0.75 kgf-m, 5.4 ft-lb) and back off 25°.

(3) Loosen the adjusting screw and apply liquid

packing to at least 1/3 of entire perimeter of its

thread.

(4) Tighten the adjusting screw to 7.4 N·m (0.75

kgf-m, 5.4 ft-lb) and back off 25°.

(5) Install the lock nut. While holding the adjust-

ing screw with a wrench, tighten the lock nut us-

ing ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39 N·m (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to pre-

vent it from turning, while tightening the lock nut.

4. TIE-ROD

1) Check the tie-rod and tie-rod ends for bends,

scratches or other damage.

2) Check the connections of knuckle ball joints for

play, inspect for damage on dust seals, and check

free play of ball studs. If the castle nut is loose, re-

tighten it to the specified torque, then tighten further

up to 60° until the cotter pin hole is aligned.

Tightening torque:

27 N·m (2.75 kgf-m, 19.9 ft-lb)

3) Check the lock nut on tie-rod end for tightness. If

it is loose, retighten it to the specified torque.

Tightening torque:

83 N·m (8.5 kgf-m, 61.5 ft-lb)

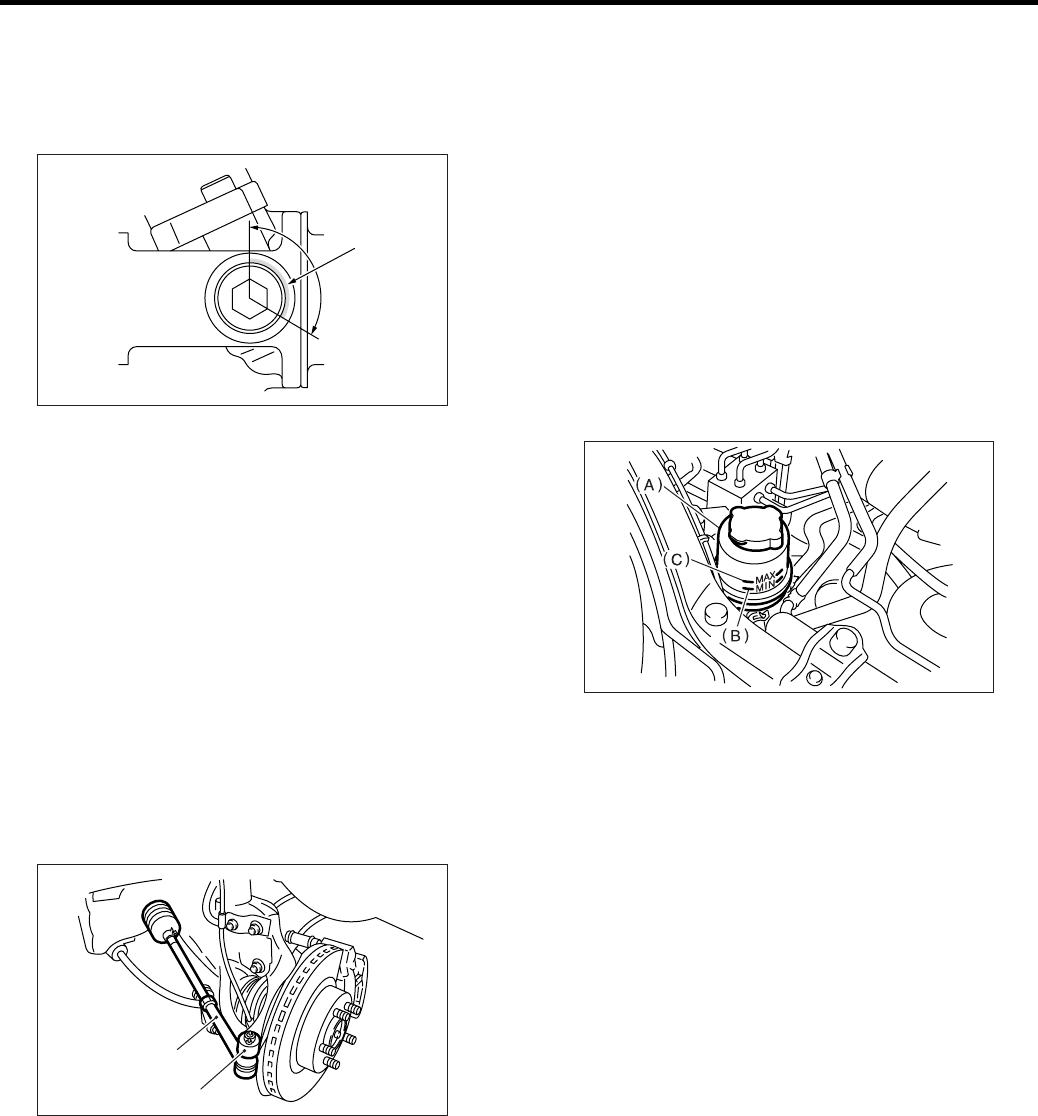

5. POWER STEERING FLUID LEVEL

NOTE:

• Check at power steering fluid temperature 20°C

(68°F); read the fluid level on the “COLD” side.

• Check at power steering fluid temperature 80°C

(176°F); read the fluid level on the “HOT” side.

1) Place the vehicle with engine “OFF” on a flat and

level surface.

2) Check the fluid level using the scale on the out-

side of reservoir tank (A). If the level is below “MIN”

(B), add fluid to bring it up to “MAX” (C).

NOTE:

If the fluid level is at MAX level or above, drain fluid

to keep the level in specified range of indicator by

using a syringe or the like.

Recommended fluid:

Dexron III

Fluid capacity:

0.7 2 (0.7 US qt, 0.6 Imp qt)

6. POWER STEERING FLUID FOR LEAKS

Inspect the underside of oil pump and gearbox for

power steering system, hoses, piping and their

couplings for fluid leaks.

If fluid leaks are found, correct them by retightening

their fitting bolts (or nuts) and/or replacing their

parts.

NOTE:

• Wipe the leakage fluid off after repairing fluid

leaks, or a wrong diagnosis is taken later.

• Also pay attention to clearances between hoses

(or pipings) and other parts when inspecting fluid

leaks.

7. HOSES OF OIL PUMP FOR DAMAGES

Check the pressure hose and return hose of oil

pump for crack, swell or damage. Replace the hose

with a new one if necessary.

(A) Apply liquid packing to at least 1/3 of entire

perimeter

(A) Tie-rod end

(B) Knuckle arm

PM-00068

(A)

PM-00069

(A)

(B)

PM-00070