PM-24

PERIODIC MAINTENANCE SERVICES

Clutch System

14.Clutch System

A: INSPECTION AND ADJUSTMENT

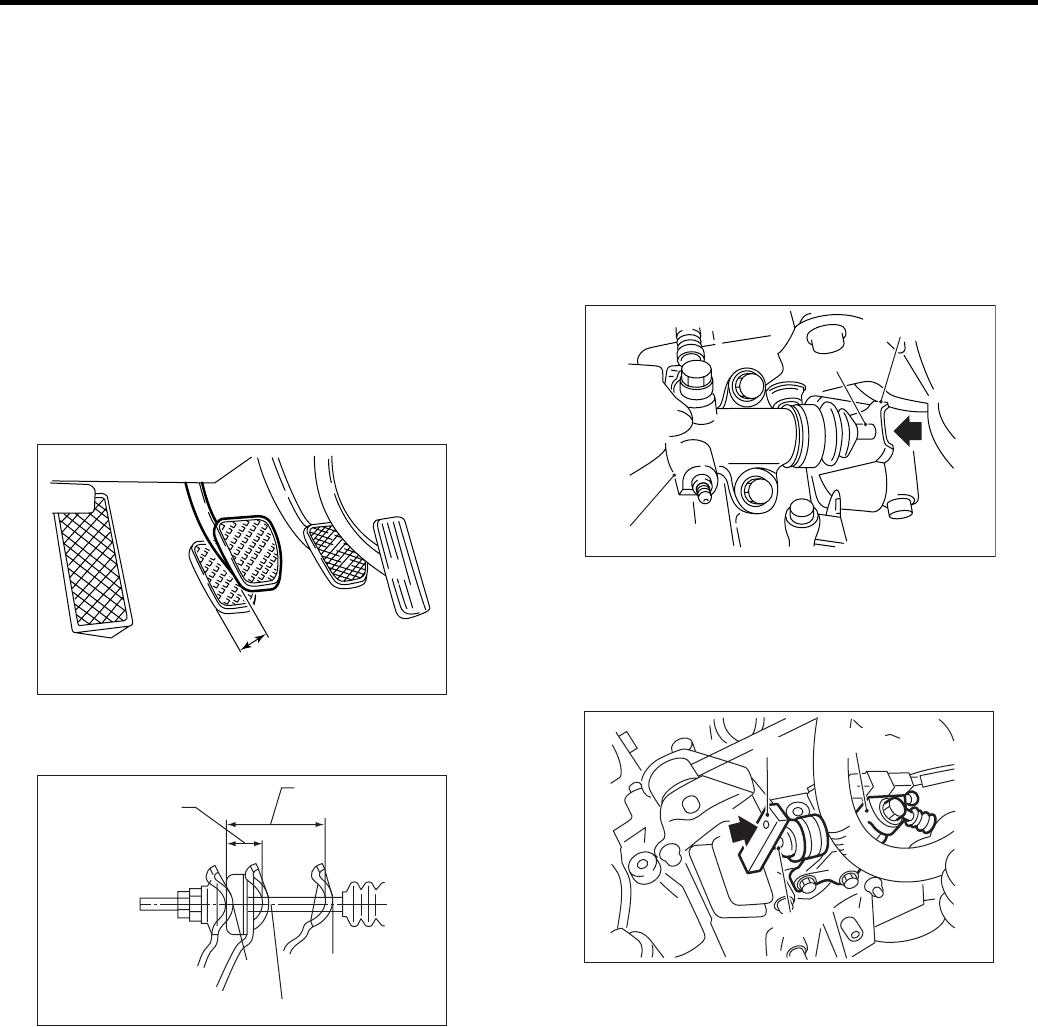

1. MECHANICAL CLUTCH TYPE

1) Inspect the free play of clutch pedal by operating

pedal by hand.

If it is out of the specified value, adjust it by turning

wing nut on engine side of clutch cable at release

fork.

Tightening torque

(Adjusting nut on release fork):

4.4 — 7.4 N·m

(0.45 — 0.75 kgf-m, 3.3 — 5.4 ft-lb)

Standard free play A:

10 — 20 mm (0.39 — 0.79 in)

Fork lever free play allowance A:

2 — 4 mm (0.08 — 0.16 in)

2) Pedal-to-floor plate gap in disengaged position.

(1) With the engine idling, pull the parking brake

lever completely.

(2) Slowly depress the clutch pedal while mov-

ing shift lever into reverse.

(3) Stop depressing the clutch pedal when

gearshifting is complete. With the clutch pedal in

this position, measure the distance between the

upper side of pedal pad and the lower end of

front panel (intersection of front panel with floor).

Check that the measured value is within the

specification.

Standard:

80 mm (3.15 in) or more

3) Pedal height

Check that the clutch pedal pad surface is level

with or higher than brake pedal pad surface.

2. HYDRAULIC CLUTCH TYPE

1) Push the release lever to retract the push rod of

the operating cylinder and check if the fluid level in

the clutch reservoir tank rises or not.

NON-TURBO MODEL

TURBO MODEL

2) If the fluid level rises, pedal free play is correct.

3) If the fluid level does not rise, or the push rod

cannot be retracted, adjust the clutch pedal. <Ref.

to CL-40, Clutch Pedal.>

4) Check the fluid level using the scale on the out-

side of the clutch master cylinder tank (A). If the lev-

el is below “MIN” (B), inspect the clutch master

cylinder, operating cylinder and hydraulic line for

fluid leaks. If fluid leaks are found, repair or replace.

If fluid leaks are not found, add clutch fluid to bring

it up to “MAX” (C) of clutch reservoir tank.

(1) Full stroke: 25.5 mm (1 in)

PM-00151

A

PM-00152

A

(1)

(A) Release lever

(B) Push rod

(C) Operating cylinder

(A) Release lever

(B) Push rod

(C) Operating cylinder

PM-00075

(A)

(C)

(B)

PM-00101

(A)

(B)

(C)