F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

21

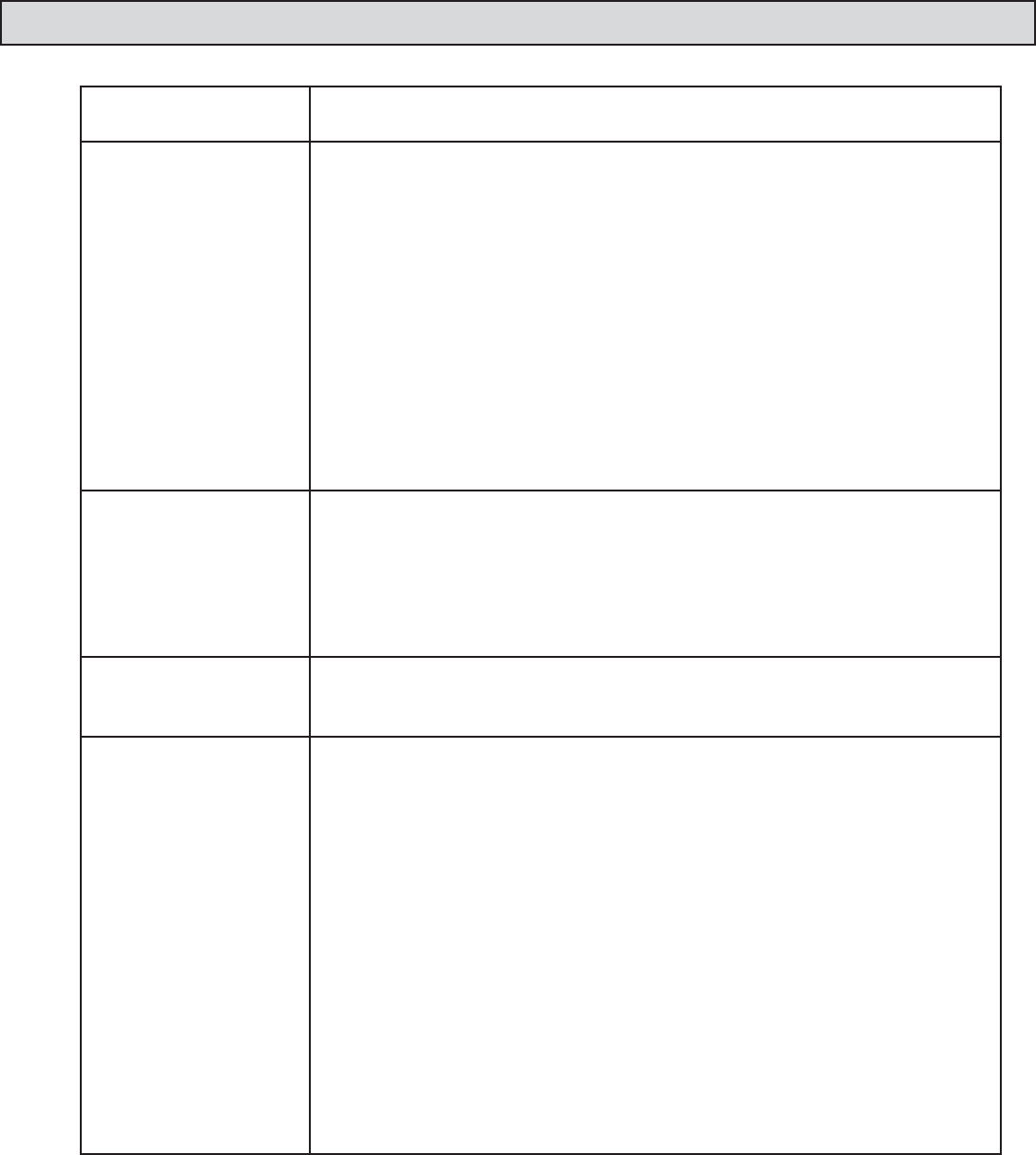

REPORTED

PROBLEM

POSSIBLE

SOLUTIONS

A non-zero fl ow indi-

cated when no actual

fl ow is in the pipe.

• Mains interference due to improper Earth ground connection. The protective

Earth PE terminal should be properly grounded (see page 17).

• Excessive mechanical vibration in the pipe. If so, support the pipeline near the

meter perpendicular to both the axis of the pipe and the axis of the shedder

bar.

• This problem may also be solved by reducing the factory set gain. (Contact

ONICON for assistance.)

NOTE: By reducing the gain, the minimum measurable fl ow rate will go up

by the factor which is approximately equal to the square root of the gains

(odd gains new gain). If the minimum fl ow with reduced gain is above the

minimum fl ow which is required to be measured, then reducing the gain is

not the permanent solution. Then the installaion should be corrected and

also the vibrations should be eliminated.

“CHECK INST.” error

is displayed when no

fl ow is in the pipe.

The display should normally indicate 0.0 fl ow rate, LOW FLOW or LOW SIGNAL

when there is no fl ow in the pipe. The additional CHECK INSTALL error (fl ow

rate = 0.0 or some steady or fl uctuating value) is an indication of:

• Improper/inadequate earthing

• Excessive pipe vibration

Flow rate inidcated is

0.0 even with fl ow in

the pipe.

• The vortex sensor cable is disconnected or is not properly connected.

• Flow sensor is faulty. Contact ONICON for assistance.

The fl ow indicated

responds to changes

in the fl ow but the

indicated value does

not correspond to the

actual fl ow rate. Also

“CHECK INST.” Error

may appear intermit-

tently.

• The meter is not properly centered on the pipeline. The axis of the meter bore

should be aligned with that of the pipe.

• Gaskets at the meter are protruding into the pipe bore. The gaskets must not

project into the effective cross-section of the pipe.

• Irregularities on the surface of the pipe bore. The pipe bore should be free from

irregularities at the welded joints, dirt, deposits and excessive surface rough-

ness.

• The Vortex signal is distorted due to a bi-phase medium. Bi-phase media are

not permitted. Use a moisture separator for wet steam applications to remove

the moisture droplets from the steam. Use suitable fi lters in gas applications to

remove solid particles from the fl owing gas. • Incorrect angular position of the

meter. Refer to Section 3.1.1 for the allowable mounting positions.

• Insuffi cient upstream/downstream pipe lengths. Check that the upstream/

downstream pipe lengths are of the correct minimum length as given in

Section 3.1.3.

• Error in meter factor K-Factor programming. Contact ONICON for assistance.

• Check that the fl ow direction and the direction arrow on the meter body agree.

4.5 TROUBLESHOOTING HINTS