F-2200 Series Vortex Flow Meter Installation and Operation Guide • Revised 12/08

20

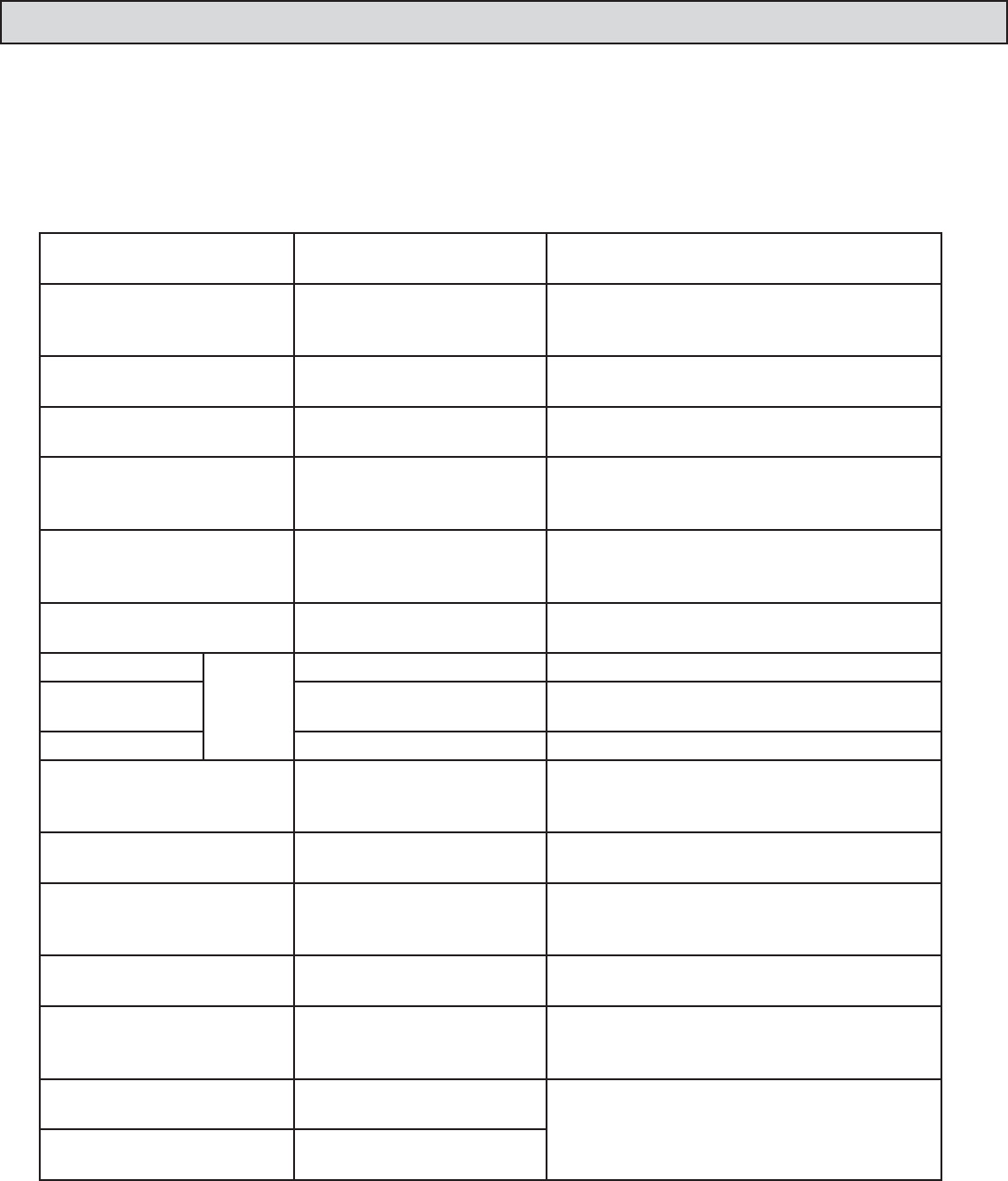

4.4 ERROR HANDLING

The meter can detect errors in either the test or the measurement modes. When in the measurement

mode, a blinking vertical bar will appear in the top left corner of the display indicating an error has

been detected. If the error reporting function is enabled, error messages will be displayed as separate

menu pages. The rst line of the error menu page indicates the total number of errors and the second

line displays the error message. Measurement mode error messages are listed below.

Error Message

(display second line)

Type Description Corrective Action

Required

NO SIGNAL No signal from the vortex

sensor

No fl ow. Also check for any other errors dur-

ing power-on diagnostics. If there is a sensor

problem, contact ONICON.

LOW FREQ. Vortex frequency is too low Check for fl ow rate lower than specifi ed mini-

mum. Contact ONICON.

HIGH FREQ. Vortex frequency is too high Check for fl ow rate higher than specifi ed maxi-

mum. Contact ONICON.

LOW FLOW Flow rate lower than speci-

fi ed range

Converter will continue to display actual fl ow

rate. However, accuracy of measurement may

suffer.

HIGH FLOW Actual fl ow rate higher than

specifi ed range

Corrective action depends on application pro-

cess. If the fl ow rate exceeds the maximum

value it may damage the sensor physically.

INV. CONFIG. Confi guration data in non-

volatile memory is not valid

Contact ONICON.

ISO FAIL Checked

during

power-

on only

Sensor isolation has failed Contact ONICON.

AMP FAIL Pre-amplifi er section has

failed

Contact ONICON.

PIEZO FAIL Piezo wires broken Contact ONICON.

CHECK INST Flow signal quality is bad Check: 1) Flow rate, if OK; 2) Check for

excessive pipe vibration and upstream fl ow

disturbances; 3) Contact ONICON.

LOW SIGNAL Vortex signal amplitude too

low

Check: 1) Flow rate, if OK; 2) Contact ONI-

CON.

HIGH SIGNAL Vortex sensor signal

amplitude too high

This occurs in cases of high density medium.

Check 1) Flow rate, if OK 2) Contact ONI-

CON.

LOW.TEMP.PHY. Operating temperature is

lower than the physical limit

Take corrective action depending on the pro-

cess.

HIGH.TEMP.PHY. Operating temperature is

higher than the physical limit

Take corrective action immediately. This will

cause damage to the shedder bar as well as

to the electronics.

T.SENS.SHORT Temperature sensor/wires

short circuit

Indicates a fault in the temperature sensor.

Contact ONICON.

T.SENS.OPEN Temperature sensor open

circuit