Parker Hannifin Corporation

Automation Actuator Division

Wadsworth, Ohio

24

Automation

PM-ER01/USA

ER Series Rodless Actuator

Maintenance Instructions and Parts List

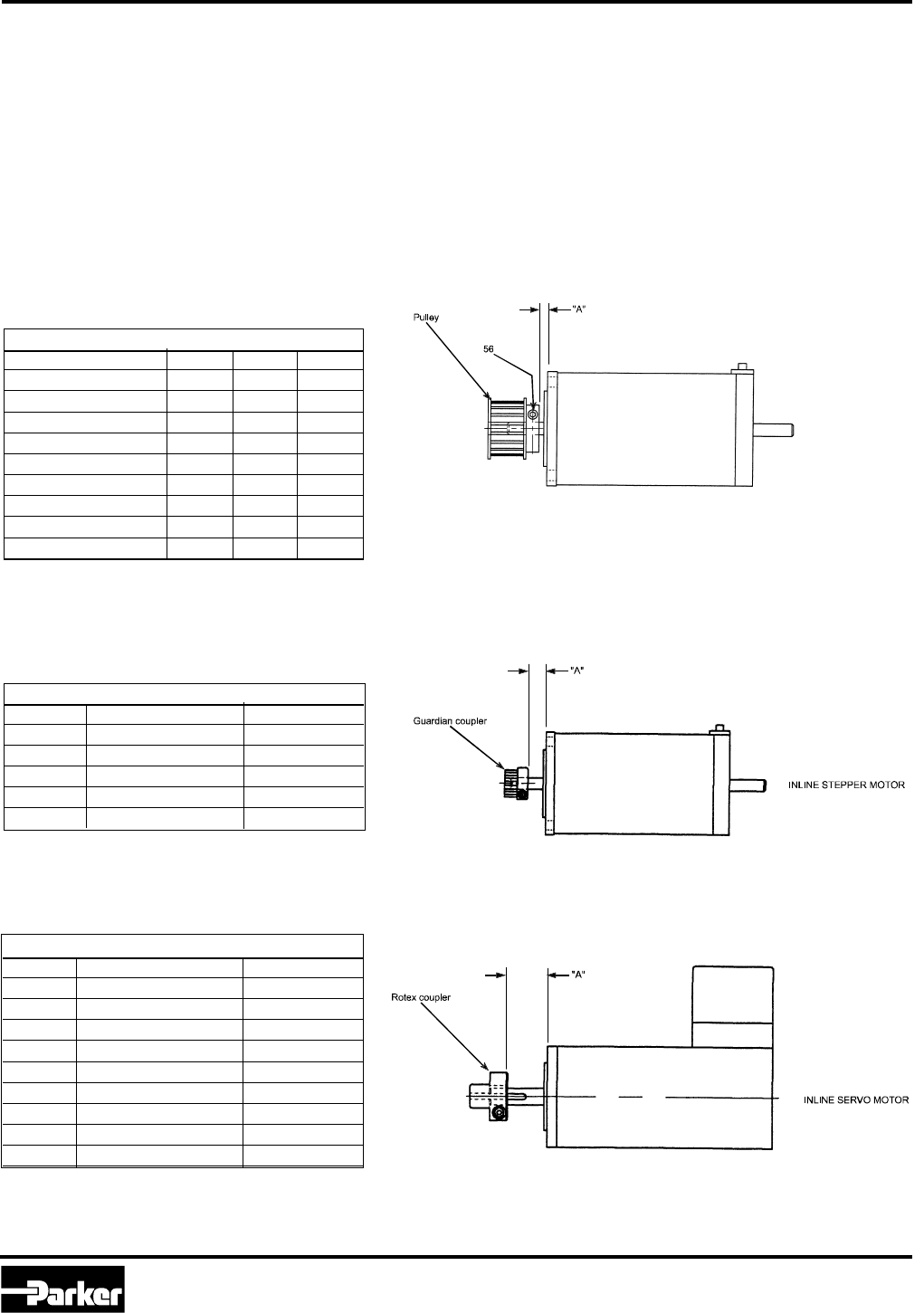

1. Determine type of motor (inline or parallel).

2. Referring to the appropriate illustration and specification table, assemble coupler to motor shaft using Loctite

609. Make sure to measure the “A” dimension from the mounting face of the motor. Do not measure off of the

pilot. Tighten set screw (if applicable).

3. Make sure to torque motor mounting hardware as necessary (if applicable). Refer to page 14 for torque

values.

NOTE: Use precautions contained with Loctite or any other adhesive used in assembly.

Motor Coupler and Pulley spacing

Motor coupler and pulley spacing refers to the required position of the coupler or pulley on the motor

shaft to ensure correct coupler or belt engagement.

Coupler and Pulley Spacing

Inline Servo Motors dimension “A”

Model Motor Dimension

ERB32 SM16 0.984

ERB32 SM233B* 0.450

ERB50 SM233B* 0.773

ERB50 J034x 0.852

ERB50 J092x, APEX605 & 606 0.749

ERB80 J034x 0.356

ERB80 J092x 0.218

ERB80 APEX605, 606, & 610 0.218

ERB80 APEX620 0.995

PARALLEL STEPPER MOTOR

Inline Stepper and DC Motors dimension “A”

Model Motor (Step, DC) Dimension

ERS32 S57-102, AD23A 0.331

ERS50 S57-102, AD23A 0.102

ERS50 S83-135, AD34A 0.693

ERS80 S83-135, AD34A 0.134

ERS80 S106-178, AD42A 0.528

Coupler Spacing

for Inline Driven Units

* T- shaft option

Pulley Spacing

for Parallel Driven Units

Motor ER32 ER50 ER80

S57-102, AD23A 0.176 0.193 —

S83-135, AD34A — 0.190 0.255

S106-178, AD42A ——0.193

SM16x 0.364 ——

SM233* 0.176 0.193 —

J034x — 0.190 0.193

J092x — 0.410 0.311

APEX605,6 ——0.311

APEX610 ——0.311

Parallel Motors dimension “A”

* T- shaft option