ENGINE <4D6> -

On-vehicle Service

11C-11

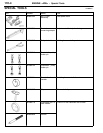

7. Turn the crankshaft clockwise to move the No.1 cylinder

approximately 30_ before compression top dead centre.

8. Set the needle of the dial gauge to 0.

9. Check that the needle doesn’t move even if the crankshaft

is turned slightly (2 - 3_) in both clockwise and

anti-clockwise direction.

NOTE

If the needle moves, the notch is not positioned properly,

so once again move the No.1 cylinder approximately 30_

before compression top dead centre.

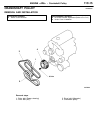

10. Turn the crankshaft clockwise to align th e No.1 cylinder

to 10_ ATDC.

11. Check that the value indicated on the dial gauge is at

the standard value.

Standard value: 1

±

0.03 mm

12. If the value is outside the standard value, adjust the

injection timing by the following procedure.

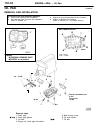

(1) Loosen the injection pipe union nuts (4 places) on

the injection pump. (Do not remove the union nuts.)

Caution

When loosening the nuts, hold the delivery valve

holders with a spanner so that they don’t turn

at the same time.

(2) Loosen the upper mounting nuts and the lower

mounting bolts of the injection pump. (Do not remove

the nut and bolt.)

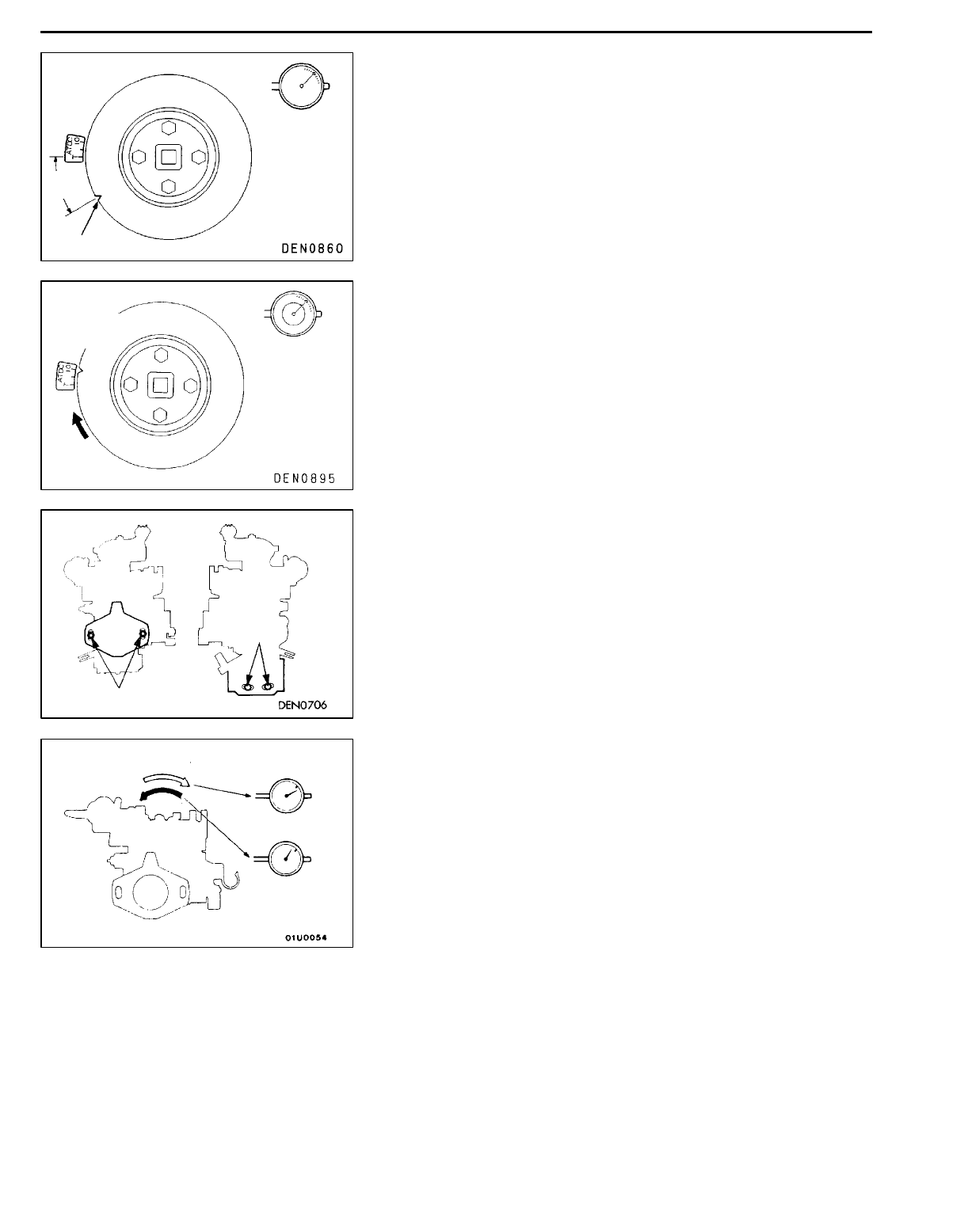

(3) Tilt the injection pump to the left or right a n d adjust

the needle on the dial gauge so that the display value

is uniform.

(4) Provisionally tighten the mounting nuts and bolts of

the injection pump.

(5) Repeat steps 7 - 12 to check if the adjustment has

been made correctly.

(6) Tighten the mounting nuts and bolts securely.

(7) Tighten the injection pump union nuts securely.

Caution

When tightening the nuts, hold the delivery valve

holders with a spanner so that they don’t turn

at the same time.

13. Remove the special tool.

14. Install a new gasket to the timing check plug.

15. Tighten the timing check plug securely.

Set to 0

Approx.

30

_

Timing mark

Set to 10

_

ATDC

1

±

0.03 mm

Nuts

Bolts

When the value is

1

±

0.03 mm or more

When the value

is 1

±

0.03 mm

or less