ENGINE <6A1> -

On-vehicle Service

11B-9

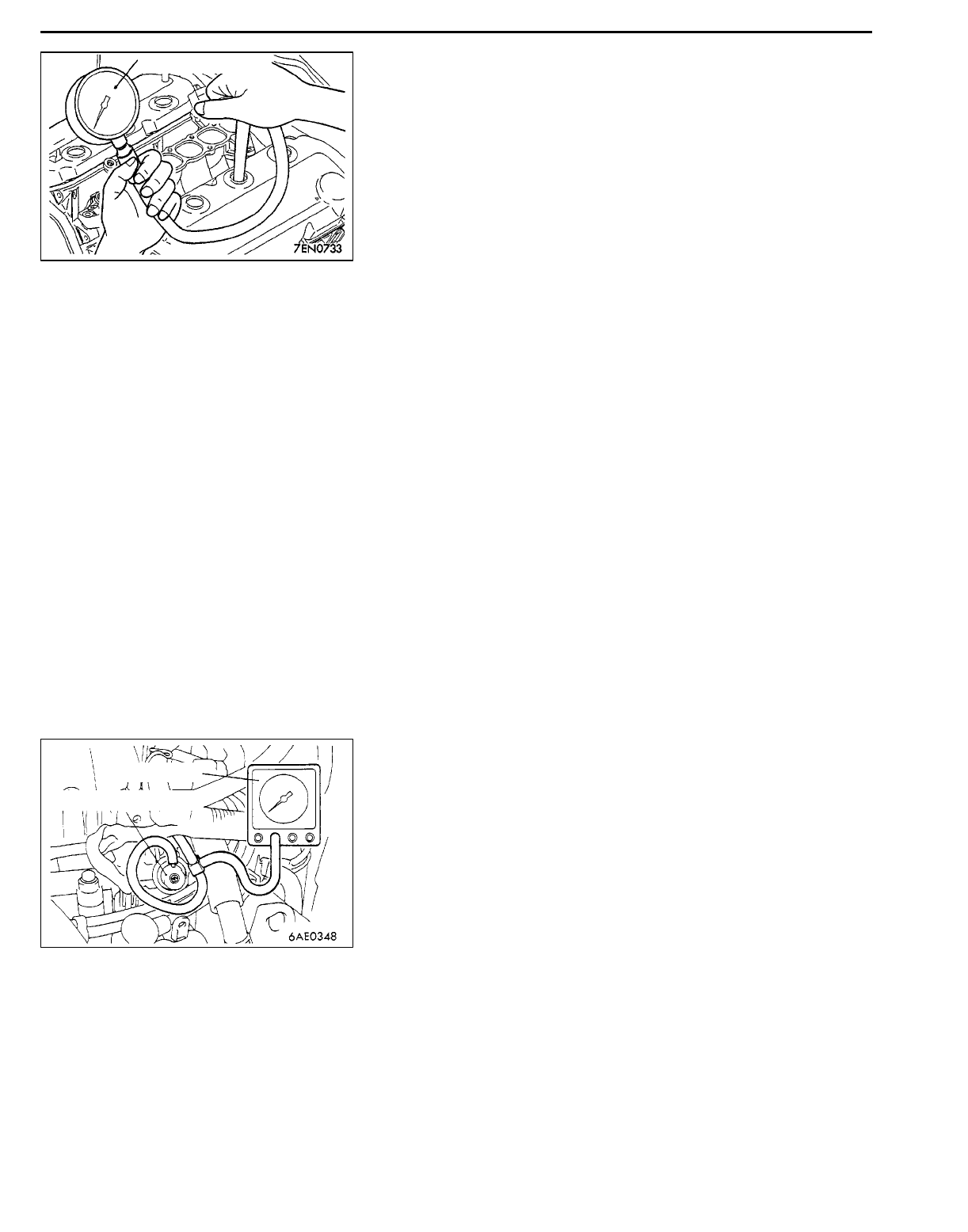

6. Set compression gauge to one of the spark plug holes.

7. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 250-400 r/min):

1,177 kPa

Limit (at engine speed of 250-400 r/min):

Min. 875 kPa

8. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders

are below the limit.

Limit: Max. 98 kPa

9. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

10. Connect the crank angle sensor connector.

11. Install the spark plugs and spark plug cables.

12. Use the MUT-II to erase the diagnosis codes.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

MANIFOLD VACUUM CHECK

11100270393

1. Start the engine and allow it to warm up until the

temperature of the engine coolant reaches 80 to 95_C.

2. Connect a tachometer.

3. Attach a three-way union to the vacuum hose between

the fuel pressure regulator and the air intake plenum,

and connect a vacuum gauge.

4. Start the engine and check that idle speed is within the

standard value. Then read off the vacuum gauge.

Limit: Min. 60 kPa

Compression gauge

Vacuum gauge

Fuel pressure regulator