96

2000

[UNIT VERIFY ERR.]

• The I/O module status is different from the I/O module

information at power ON.

• The I/O module (or intelligent function module) is nearly

removed, completely removed, or mounted during running.

■Collateral information

• Common Information (SD5 to SD15): Network No./Station

No.

• Individual Information (SD16 to SD26): -

■Diagnostic Timing

• Always

• Read common information of the error using GX

Works2 or GX Developer to identify the numeric

value (module No.). Check the module

corresponding to the value and replace it as

necessary.

• Monitor the special register SD1400 to SD1431 using

GX Works2 or GX Developer to identify the module

whose data bit is "1". Then check the module and

replace it as necessary.

REM: Off

ERR: On

Remote I/O status:

Stop/Continue

*1

2011

[BASE LAY ERROR]

The QA1S6B or QA6B was used as the base unit.

■Collateral information

• Common Information (SD5 to SD15): Base No.

• Individual Information (SD16 to SD26): -

■Diagnostic Timing

• At power-on/At reset

*2

Do not use the QA1S6B or QA6B as the base unit.

REM: Off

ERR: On

Remote I/O status: Stop

2100

[SP. UNIT LAY ERR.]

• In the I/O Assignment tab of the PLC parameter dialog

box, "Intelligent" (intelligent function module) is set for the

slot where an I/O module is mounted, and vice versa.

• In the I/O assignment setting of the PLC parameter, switch

setting was made to the module that has no switch setting.

• In the I/O assignment setting of the PLC parameter dialog

box, the number of points assigned to the intelligent

function module is less than the number of points of the

mounted module.

[NET/10 mode]

• In the I/O Assignment tab of the PLC parameter dialog box

or the I/O assignment setting of the network parameter,

"Intelligent" (intelligent function module or special function

module) is set for the slot where an I/O module is mounted,

and vice versa.

• In the I/O assignment setting of the PLC parameter, switch

setting was made to the module that has no switch setting.

• In the I/O assignment setting of the PLC parameter dialog

box or the I/O assignment setting of the network

parameter, the number of points assigned to the intelligent

function module (special function module) is less than the

number of points of the mounted module.

■Collateral information

• Common Information (SD5 to SD15): Module No.

• Individual Information (SD16 to SD26): -

■Diagnostic Timing

• At power-on/At reset

*2

• Set the I/O assignment again so that the setting

matches with the mounting status of the intelligent

function module or the remote I/O module.

• Delete the switch setting in the I/O assignment

setting of the PLC parameter.

[NET/10 mode]

• Set the I/O assignment of the PLC parameter or the

I/O assignment of the network parameter again so

that the setting matches with the mounting status of

the intelligent function module (special function

module) or the remote I/O module.

• Delete the switch setting in the I/O assignment

setting of the PLC parameter.

REM: Off

ERR: On

Remote I/O status: Stop

2103

[SP.UNIT LAY ERR.]

The QI60 is mounted.

■Collateral information

• Common Information (SD5 to SD15): Module No.

• Individual Information (SD16 to SD26): -

■Diagnostic Timing

• At power-on/At reset

*2

Remove the QI60.

REM: Off

ERR: On

Remote I/O status: Stop

2106

[SP.UNIT LAY ERR.]

• Five or more Q series Ethernet modules are mounted.

• 65 or more Q series CC-Link modules are mounted.

■Collateral information

• Common Information (SD5 to SD15): Module No.

• Individual Information (SD16 to SD26): -

■Diagnostic Timing

• At power-on/At reset

*2

• Reduce the number of the Q series Ethernet

modules to four or less.

• Reduce the number of the Q series CC-Link modules

to 64 or less.

REM: Off

ERR: On

Remote I/O status: Stop

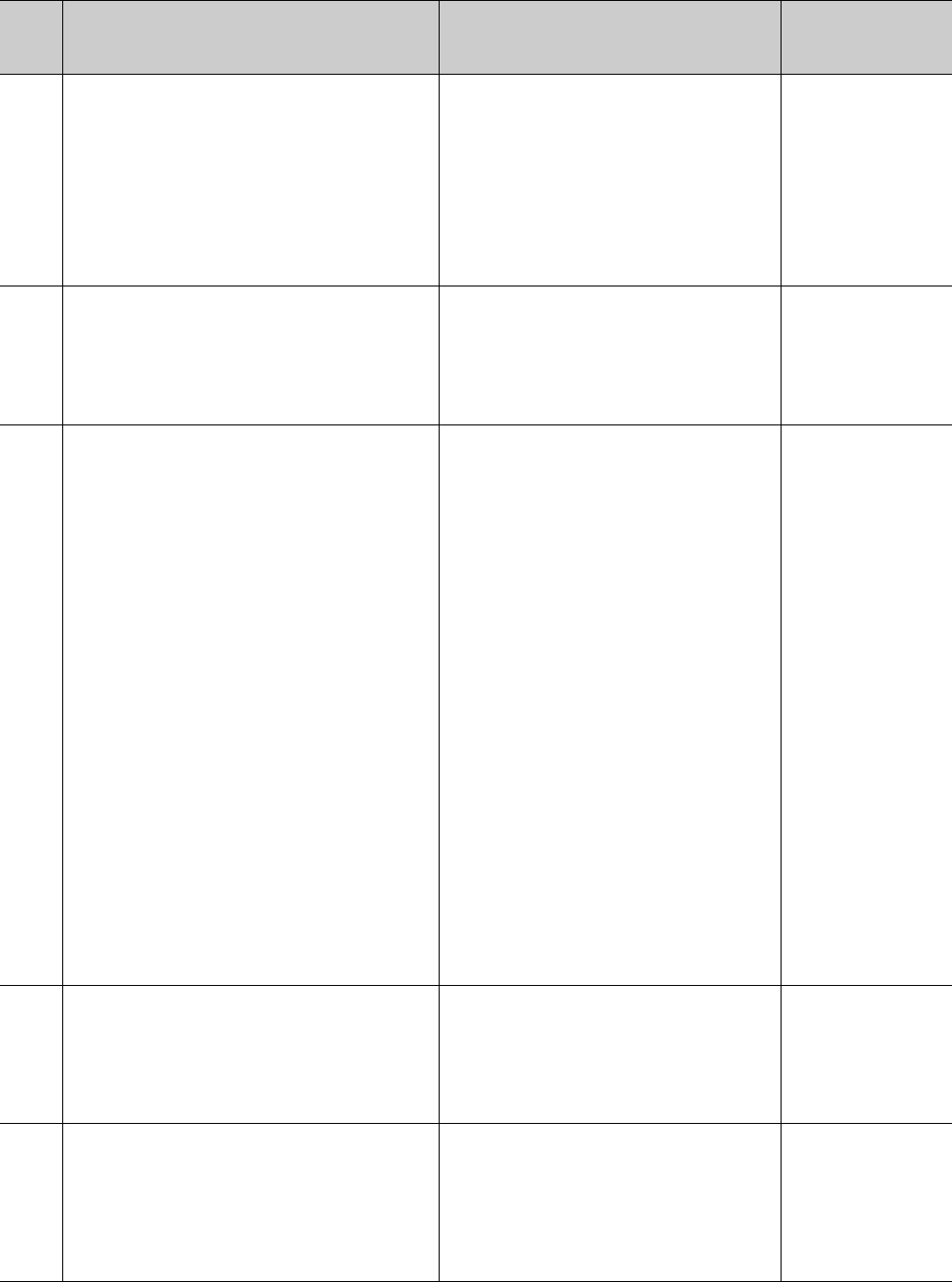

Error

code

(SD0)

Error contents and cause Corrective action

LED status,

Remote I/O operation

status