Bettis P/N 124840E

Revision “B”

Page 21 of 46

3.3.23.2.2 Install the jackscrew (3-290) through the outboard side of the outer

end cap (3-80).

3.3.23.2.3 Apply a light coating of lubricant to threads of jackscrew (3-290).

3.3.23.2.4 Screw jackscrew adapter (3-280) onto jackscrew (3-290). NOTE:

The small round end of the M3 adapter will install on the jackscrew

pointing to the inboard end of the jackscrew.

3.3.23.2.5 Position the jackscrew with the inboard end of the jackscrew located

with the needle bearing thrust washer assembly (3-340) up against

or near the jackscrew adapter (3-280).

3.3.23.2.6 Install outer end cap (3-80) over tie bars (3-20) and into cylinder

(3-70).

3.3.23.2.7 Install tie bar nuts (3-90) onto tie bars (3-20). NOTE: Do not tighten

nuts.

3.3.23.2.8 Install two socket cap screws (3-320) through jackscrew adapter (3-

280) and tighten into the outer end cap (3-80).

3.3.23.2.9 Lightly lubricate o-ring seal (4-150) and install onto the outboard end

of the jackscrew. Push the o-ring (4-150) down the jackscrew until it

contacts the jackscrew adapter (3-280).

3.3.23.2.10 Install flat hex nut (3-300) onto jackscrew (3-290). Rotate the flat

hex nut (3-300) until it is up against the o-ring seal (4-150).

3.3.23.2.11 Install outer end cap (3-80) over tie bars (3-20) and into cylinder

(3-70). Continue at step 3.3.24

3.3.23.3 STANDARD OUTER END CAP INSTALLATION Install outer end cap

(3-80) over tie bars (3-20) and into cylinder (3-70).

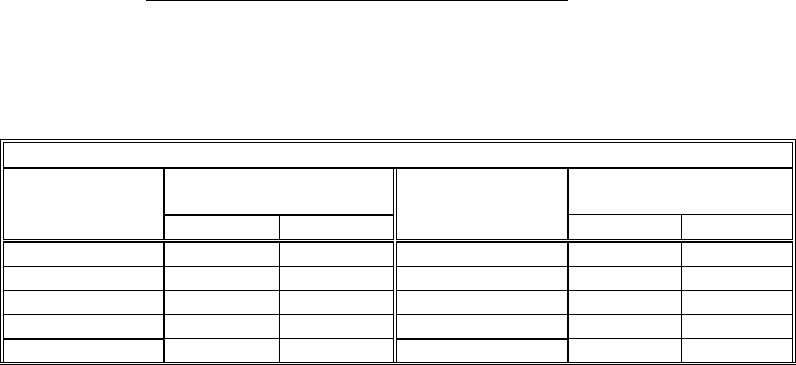

3.3.24 Install tie bar nuts (3-90) onto tie bars (3-20). Torque tighten tie bar nuts, alternately in 100

foot pound / N-m increments, until a final lubricated torque, as listed in the following table, has

been achieved.

TIE BAR NUTS

TORQUE

(±5 % Percent)

TORQUE

(±5 % Percent)

HOUSING

MODEL

FT-lb. N-m

HOUSING

MODEL

FT-lb. N-m

G01 120 163 G7 500 678

G2 120 163 G8 500 678

G3 150 203 G10 1200 1627

G4 150 203 G13 1600 2169

G5 400 542