Instruction Manual MM850481 ed.01

4 PRINCIPLE OF OPERATION

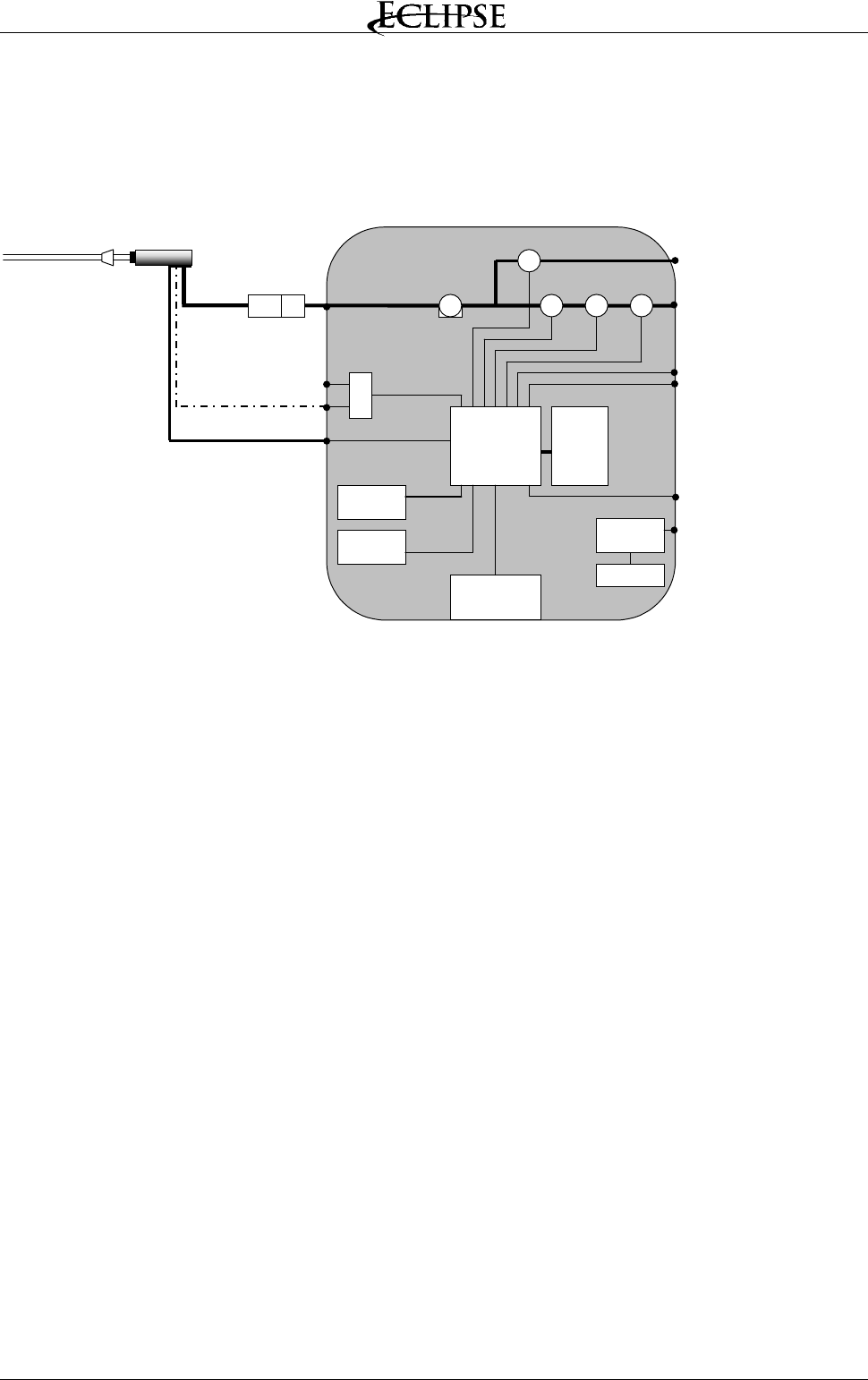

The EGA4 analyzer is based on the following functional blocks:

MicroController

Impact printer

Keyboard

Display

250

memory

Power supply

Ni-MH battery

Battery charger input

External probe input

Pt100 Tair input

Gas outlet

P2 -

∆

P

P1 – Draft/Pressure

Differential

pressure

sensor

Gas input

INLET

Pump 1° Sensoe O2

3° Sensor

TcK Tgas inpu

t

Water trap

Line filter

IR serial port

2° Sensor CO

4° Sensor

4.1 Measurement principle

The gas is sampled and aspirated through the probe with a primary pump powered at constant voltage.

To position the sampling probe in the exhaust gas pathway a hole of 11mm, up to 16mm, should be drilled and the

retaining cone of the sampling probe firmly screwed in it.

The retaining screw in the cone enables the probe to be easily moved to locate the core flow, normally correspondent to

the center of the section of the smoke tube. The flue gas and exhaust gas pathway, should be checked for gas-tightness

before carrying out a measurement and, if necessary, non gas-tight points should be sealed.

The O

2

sensor is essentially an electrochemical cell, with two electrodes and electrolyte solution. The behavior is similar

to a normal battery and therefore the sensitivity decreases with time. The expected life does not relate to the operative

time and is lost after approximately 24 months.

The toxic gas measurements (CO, SO

2

, NO and NO

2

) use electrochemical cells, with an expected operative life of 3

years.

The electrochemical cell grants accurate results for time intervals of approximately 60 minutes. The zero drift is

automatically corrected by the instrument every time the instrument is switched-on, using fresh ambient air as reference.

This operation should be made with the sampling probe not inserted in the chimney or with the sampling probe

pneumatic connector disconnected from the analyzer gas inlet.

When a long time analysis has to be made, a new autozero procedure should be performed.

The pressure/draught sensor is based on the principle of the extension metric measuring bridge. When the instrument is

switched-on, a zero calibration of the draught/pressure circuit is also executed. Leave open the “∆P” connector during

this phase.

Measured and calculated parameters are indicated on a LCD alphanumeric display (40x56 mm), equipped with a

automatic back light device for easy readings, also in poor light conditions.

4.1.1 Gas sampling probe

The sampling probe consists of a steel tube and a handle of thermoinsulating material. A positioning cone allows to place

the probe in holes with a diameter from 11 to 16 mm.

The gas temperature is acquired using a thermocouple type K with the junction placed on the top of the tip.

11