Ignition

23

Test the engine stop switch

To test the engine stop switch:

1. Open the grip by removing the five screws with a T-20

torx driver.

2. Disconnect the wires from the engine stop switch.

3. Connect an ohm meter or continuity light to the

switch.

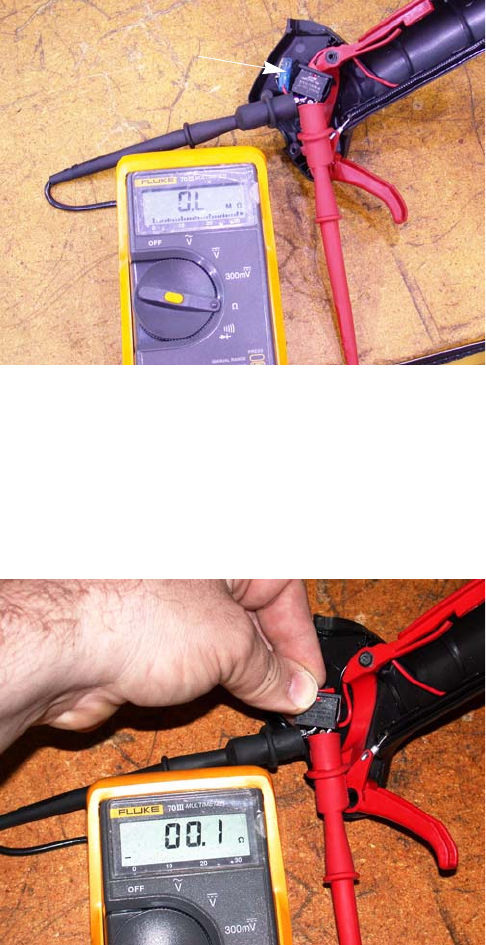

4. With the switch in the engine run position (l), the

meter should indicate no continuity. See Figure 4.3.

NOTE: Most stop switches are spring loaded to the run

position when it is released. This prevents no-start

situations caused by the customer failing to turn

the switch on.

5. Hold the switch in the stop position (0). The meter

should indicate continuity. See Figure 4.4.

• If the results are not as described, the switch is

bad and should be replaced.

• If the switch is working properly, there is a short in

the wires.

NOTE: If there is reason to suspect that the ignition timing

is off:

• Remove the starter by following the steps

described in Chapter 6: Starter.

• Make sure the module air gap is correct by follow-

ing the steps described in the module section of

this chapter.

• Inspect the flywheel. If the flywheel is damaged,

replace the flywheel.

• Remove the flywheel by following the steps in the

flywheel section of this chapter.

• Inspect the flywheel key, if damaged replace the

key.

• Inspect the key way on the crank shaft for damage,

if damaged short block the engine.

6. Assemble and test run the engine before returning it

to service.

Figure 4.3

Switch in the engine

run position

Figure 4.4